A kind of preparation method of large particle pentaerythritol co-production potassium formate

A technology of pentaerythritol and large particles, which is applied in the field of preparation of large particle pentaerythritol co-production potassium formate, can solve the problems of product purity affecting filtration performance, different crystal particle sizes, uncontrolled cooling rate, etc., and achieve regular crystal shape, uniform distribution, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

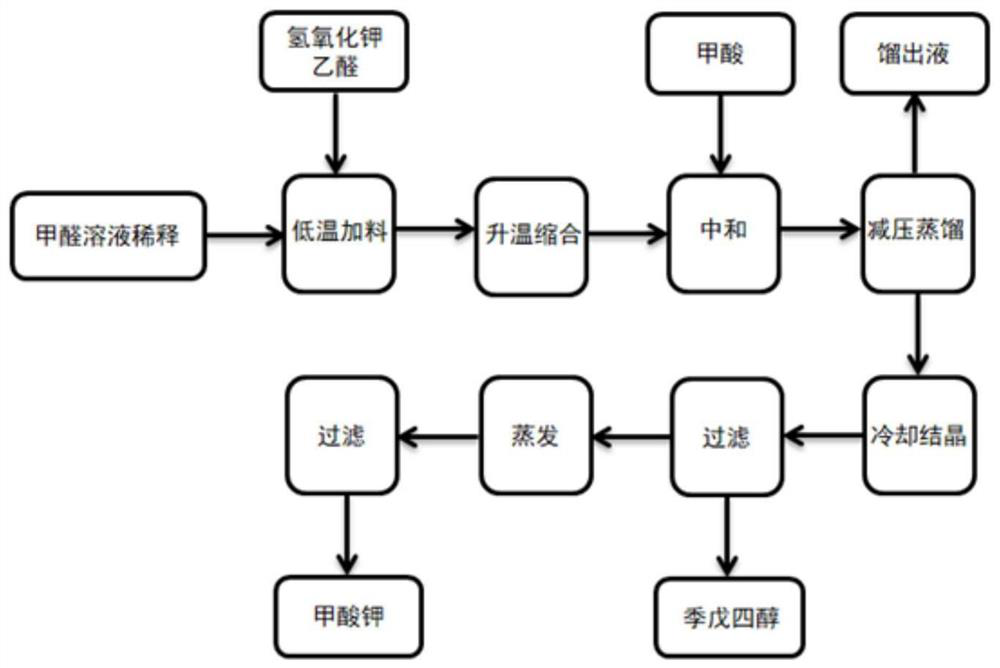

[0023] Such as figure 1 As shown, the present invention provides a kind of preparation method of large particle pentaerythritol co-production potassium formate, comprises the following steps: step 1, industrial formaldehyde solution is diluted to certain concentration, and the potassium hydroxide solution of certain concentration and acetaldehyde solution are proportional Slowly add to the formaldehyde solution to react, and keep the low temperature reaction; step 2, the solution obtained after the low temperature reaction in step 1, after raising the reaction temperature, to obtain a condensation liquid, add an appropriate amount of formic acid solution dropwise to the condensation liquid, adjust Solution pH value; Step 3, the solution obtained after adjusting the pH value in Step 2 is subjected to vacuum distillation to remove a part of solvent; Step 4, The first mother liquor obtained in Step 3 is crystallized by cooling and filtered to obtain the second mother liquor, and t...

Embodiment 1

[0037] A. Take 118.0511g of 34.00% formaldehyde solution, add water to make 160g / L solution;

[0038] B. Weigh 13.0502g of potassium hydroxide solid, add water to make 160g / L solution, take 10.1512g of acetaldehyde solution (the mass content of acetaldehyde is 99%) at the same time, add the two slowly to the solution obtained in step A, and keep the reaction temperature during The temperature is 10-15°C, and the dropwise reaction time is 1h; the molar ratio of formaldehyde: acetaldehyde: potassium hydroxide = 4:1:1.3 is added in proportion.

[0039] C. After the dropwise addition, raise the reaction temperature to 35° C., and the reaction time is 1 h. After the reaction, use formic acid to adjust the pH value of the solution to 6;

[0040] D. Distill the solution obtained in step C under reduced pressure, the vacuum degree is 0.09Mpa, the distillation temperature is 80°C to 90°C, and 80% of the liquid is controlled to evaporate, and the obtained mother liquor is crystallized ...

Embodiment 2

[0043] A. Take 118.0511g of 36.00% formaldehyde solution, add water to make 170g / L solution;

[0044] B. Weigh 13.0502g potassium hydroxide solid, add water and be mixed with 160g / L solution, get 10.1512 acetaldehyde solution (acetaldehyde content is 99%) simultaneously, both slowly add in the solution that A step obtains. During the period, keep the reaction temperature at 20-25°C, and the dropwise reaction time is 1h; add the molar ratio formaldehyde: acetaldehyde: potassium hydroxide = 4.1:1:1.15 in proportion;

[0045] C. After the dropwise addition, raise the reaction temperature to 38°C, and the reaction time is 1.2h. After the reaction, use formic acid to adjust the pH of the solution to a range of 6.25.

[0046] D. The solution obtained in step C is subjected to vacuum distillation, the vacuum degree is 0.095Mpa, the distillation temperature is 80°C to 90°C, and 82.5% of the liquid is controlled to evaporate, and the obtained mother liquor is cooled and crystallized a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com