Method for fractionation of soybean 7S globulins and 11S globulins of low phytic acid

A technology for fractionation and soybean protein, applied in the field of fractions rich in 11S globulin, which can solve the problems of solubility change, reduction of phytic acid enrichment, impact on component purity, etc., to improve fractionation efficiency, increase nutritional value, Effect of avoiding the desalination step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

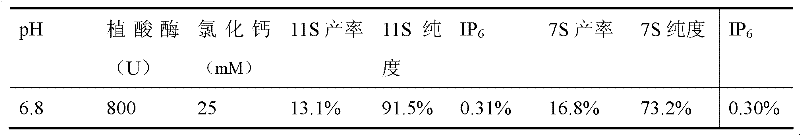

[0028] The defatted soybean meal (NSI=91, protein weight content 49%) was crushed and passed through a 60-mesh sieve to obtain defatted soybean powder, mixed with water at a mass ratio of 1:15, extracted at room temperature and pH 8.0 for 1 hour, and then centrifuged The defatted soybean protein extract is obtained. The obtained defatted soybean protein extract was adjusted to pH 5.8 with hydrochloric acid and heated to 40°C. Add phytase ("PHYTASE", produced by BASF, Germany) to the solution (phytic acid content is 1.80% by weight of protein) in an amount of 800 μ per gram of protein, and perform enzyme treatment for 2 hours. Adjust the pH to 6.8 with 2mol / L hydrochloric acid, and add calcium chloride, the concentration of calcium chloride in the solution is 25mM. After stirring at room temperature for 10 min, centrifuge with a batch centrifuge (3000 g) to separate the soluble part containing 7S globulin and the insoluble part containing 11S globulin, and the feed solution is...

Embodiment 2

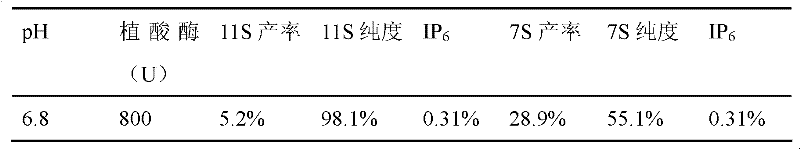

[0041] The defatted soybean meal (NSI=91, protein content 49%) was crushed and passed through a 60-mesh sieve to obtain defatted soybean powder, mixed with water at a mass ratio of 1:15, extracted at room temperature and pH 8.0 for 1 hour, and then centrifuged to obtain Defatted Soy Protein Extract. The resulting defatted soybean milk was adjusted to pH 6.8 with hydrochloric acid and heated to 50°C. Add German BASF "PHYTASE" phytase to this solution (phytic acid content is 1.80% protein weight), the addition amount is 600 μ of phytase per gram of protein, and carry out enzyme treatment for 2 hours. Adjust the pH to 6.4 with 2mol / L hydrochloric acid, add 5mM calcium chloride, stir at room temperature for 10min, and use a decanter to separate the soluble part containing 7S globulin and the insoluble part containing 11S globulin. part. During centrifugation, the feed solution was kept at room temperature. The electrophoretic patterns of the soluble and insoluble fractions afte...

Embodiment 3

[0050] The defatted soybean meal (NSI=91, protein content 49%) was crushed and passed through a 60-mesh sieve to obtain defatted soybean powder, mixed with water at a mass ratio of 1:15, extracted at room temperature and pH 8.0 for 1 hour, and then centrifuged to obtain Defatted Soy Protein Extract. The resulting defatted soybean milk was adjusted to pH 3 with hydrochloric acid and heated to 40°C. Add German BASF "PHYTASE" phytase (German BASF "PHYTASE") to this solution (phytic acid content: 1.80% protein weight), the addition amount is 1000 μ per gram of protein, and carry out enzyme treatment for 1 hour. Adjust the pH to 5.8 with 2mol / L hydrochloric acid, add 5mM calcium chloride, stir at room temperature for 10min, and centrifuge with a batch centrifuge (3000g) to separate the soluble fraction containing 7S globulin and 11S globulin the insoluble part. Compared with Comparative Example 3, the purity of the 11S component and the 7S component is higher. Correspondingly, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com