One-step Preparation of Shrimp Shell with Modified Chitin Fiber and Its Application

A chitin fiber and modification technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of poor adsorption performance of metal oxides, environmental pollution of reagents, complicated processes, etc., to increase transparent conductivity and reduce reagents. Dosage, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

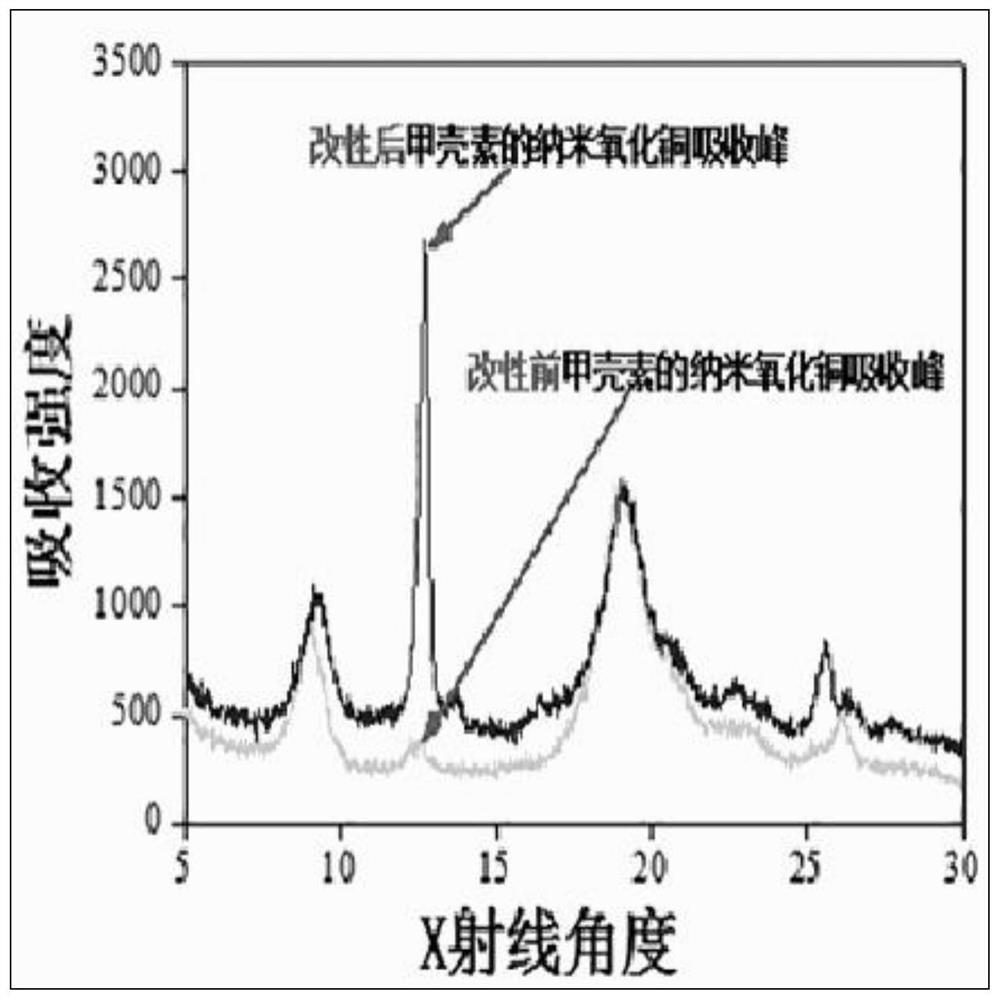

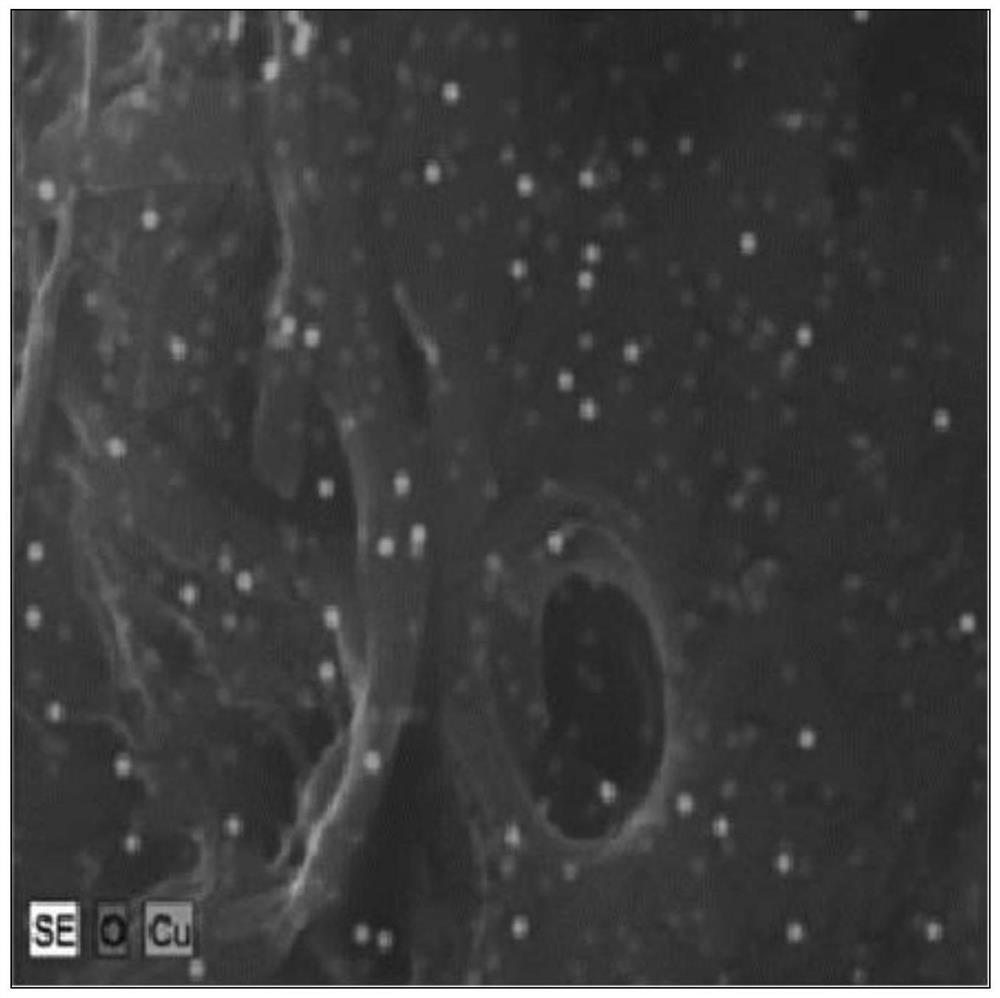

[0022] First dry the shells of Antarctic krill at 60°C for 24 hours, pulverize them with an ultrafine pulverizer, and squeeze them through a 1000-mesh sieve to obtain micron-sized Antarctic krill shell powder; then transfer 10g of shrimp shell powder to a 500mL sub In the aqueous solution of sodium aminodisuccinate, the concentration of the aqueous solution of sodium iminodisuccinate is 18% (w:v), add 15g of potassium persulfate and 25g of hydrogen peroxide, seal it, stir it while heating at 40°C for 2h, filter the product, The filter residue was washed with deionized water until neutral to obtain modified chitin fibers. Then, the modified chitin fiber was transferred into the acetic acid solution with pH value = 3 according to the solid-liquid ratio of 1g:50mL, ultrasonicated at 900W, 50Hz, and ice bath for 30min, and then centrifuged at 12000rpm at 4°C for 30min, and the upper supernatant; finally, the supernatant was diluted with deionized water, and the water was evaporate...

Embodiment 2

[0024] First dry 100g of Antarctic krill shells at 70°C for 18 hours, pulverize them with a superfine pulverizer, and squeeze them through a 1000-mesh sieve to obtain micron-sized Antarctic krill shell powder; then take 10g of shrimp shell powder and transfer it to a 300mL In the aqueous solution of sodium iminodisuccinate, the concentration of the aqueous solution of sodium iminodisuccinate is 10% (w:v), add 0.3g potassium persulfate and 30g hydrogen peroxide, seal it, and stir it while heating at 30°C for 3h, the product After filtering, the filter residue was washed with deionized water until neutral to obtain modified chitin fibers. Then the modified chitin fiber was transferred into the acetic acid solution with pH value = 2 according to the solid-liquid ratio of 1g:40mL, ultrasonicated at 900W, 50Hz, and ice-bathed for 40min, then centrifuged at 11000rpm at 4°C for 60min, and the upper supernatant; finally, the supernatant was diluted with deionized water and evaporated ...

Embodiment 3

[0026] First dry 100g of Antarctic krill shells at 50°C for 24 hours, pulverize them with a superfine pulverizer, and squeeze them through a 1000-mesh sieve to obtain micron-sized Antarctic krill shell powder; In the aqueous solution of sodium iminodisuccinate, the concentration of the aqueous solution of sodium iminodisuccinate is 25% (w:v), add 40g of potassium persulfate and 0.4g of hydrogen peroxide, seal it, and stir it while heating at 45°C for 0.5h. The product is filtered, and the filter residue is washed with deionized water until neutral to obtain modified chitin fibers. Then, the modified chitin fiber was transferred into the acetic acid solution with pH value = 4 according to the solid-liquid ratio of 1g:60mL, ultrasonicated at 900W, 50Hz, and ice-bathed for 30min, and then centrifuged at 10000rpm at 4°C for 50min. supernatant; finally, the supernatant was diluted with deionized water, and the water was evaporated to dryness in an oil bath at 110°C to obtain a flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com