Composite rubber water-stopping belt

A technology for compounding rubber and waterstop, which is applied in microcapsule preparation, microsphere preparation, etc., can solve the problem of large spacing between reinforcing plates, and achieve the effect of improving breaking strength, avoiding decline, and avoiding gradual loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

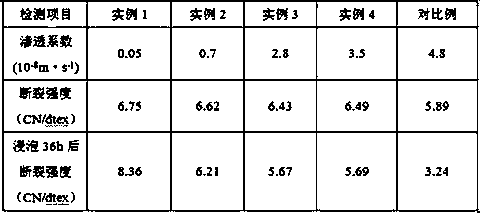

Examples

example 1

[0033] In parts by weight, successively take 20 parts of graphene oxide, 40 parts of toluene diisocyanate, and 40 parts of acetone, after mixing, heat and reflux for 5 hours, then filter, wash and vacuum-dry to obtain isocyanate-modified graphene oxide; In parts by weight, weigh in turn: 300 parts of deionized water, 100 parts of sodium chloride, 2.5 parts of magnesium hydroxide, 10 parts of magnesium chloride hexahydrate, 2 parts of dispersant, mix deionized water with sodium chloride, and add to Add magnesium hydroxide, magnesium chloride hexahydrate and a dispersant to the mixture of deionized water and sodium chloride, and stir and mix for 40 minutes at a temperature of 50°C and a rotating speed of 400r / min to obtain an aqueous phase mixture; Count and weigh in turn: 15 parts of acrylonitrile, 3 parts of vinylidene chloride, 12 parts of methyl methacrylate, 3 parts of butyl acrylate, 20 parts of low boiling point foaming agent, 4 parts of initiator and 5 parts of crosslinki...

example 2

[0035] In parts by weight, weigh in turn: 300 parts of deionized water, 100 parts of sodium chloride, 2.5 parts of magnesium hydroxide, 10 parts of magnesium chloride hexahydrate, 2 parts of dispersant, mix deionized water with sodium chloride, and Add magnesium hydroxide, magnesium chloride hexahydrate and a dispersant to the mixture of deionized water and sodium chloride, and stir and mix for 40 minutes at a temperature of 50°C and a rotation speed of 400r / min to obtain an aqueous phase mixture; by weight Count by parts, weighing in order: 15 parts of acrylonitrile, 3 parts of vinylidene chloride, 12 parts of methyl methacrylate, 3 parts of butyl acrylate, 20 parts of low boiling point foaming agent, 4 parts of initiator and 5 parts of crosslinking agent, mix acrylonitrile and methyl methacrylate, and add vinylidene chloride, butyl acrylate, low boiling point foaming agent, initiator and crosslinking agent to the mixture of acrylonitrile and methyl methacrylate, at temperatur...

example 3

[0037]In parts by weight, weigh in turn: 20 parts of styrene, 12 parts of divinylbenzene, 5 parts of benzoyl peroxide, 15 parts of epoxy resin, 12 parts of propylene oxide butyl ether, 7 parts of surfactant And 50 parts of deionized water, surfactant and deionized water are mixed in the there-necked flask, add styrene, divinylbenzene, divinylbenzene, epoxy resin and propylene oxide butyl ether in the there-necked flask, And pass nitrogen gas into the three-necked flask at a rate of 30mL / min, under the conditions of temperature 80°C and rotation speed 350r / min, stir and react for 8h, filter to obtain microcapsule blanks, and deionize the microcapsule blanks with deionized water After washing 10 times, dry at a temperature of 80°C for 3 hours to obtain microcapsules; in parts by weight, weigh in turn: 60 parts of nitrile rubber, 40 parts of natural rubber, 30 parts of chlorinated polyethylene rubber, 10 parts Parts of plasticizer, 5 parts of heat stabilizer, 12 parts of vulcaniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com