Metal oxide composite material and preparation method thereof and application of metal oxide composite material

A technology of composite materials and oxides, which is applied in electrical components, battery electrodes, alkaline storage batteries, etc., can solve the problems of easy agglomeration of nano-zinc oxide and uneven modification of metal oxides, so as to achieve slow desorption of hydrogen and passivation, and improve Effect of Cycle Efficiency and Cycle Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Weigh 0.75g zinc nitrate hexahydrate, 0.035g stannous chloride dihydrate, 0.015g aluminum chloride and dissolve in 50ml DMF, dissolve 0.2g terephthalic acid, 1gPVP, 40μlTEA in another 50ml DMF .

[0034] 2) Slowly pour the latter solution into the former solution in step 1 and sonicate at 30°C for 15 minutes; the ultrasonic frequency is 30kHz, transfer the obtained mixed solution into a polytetrafluoroethylene liner with a steel shell, and react at 120°C for 8 hours; Cool to room temperature, centrifuge to separate the product, wash with ethanol 3 times, and vacuum dry at 100°C for 12 hours to obtain the precursor;

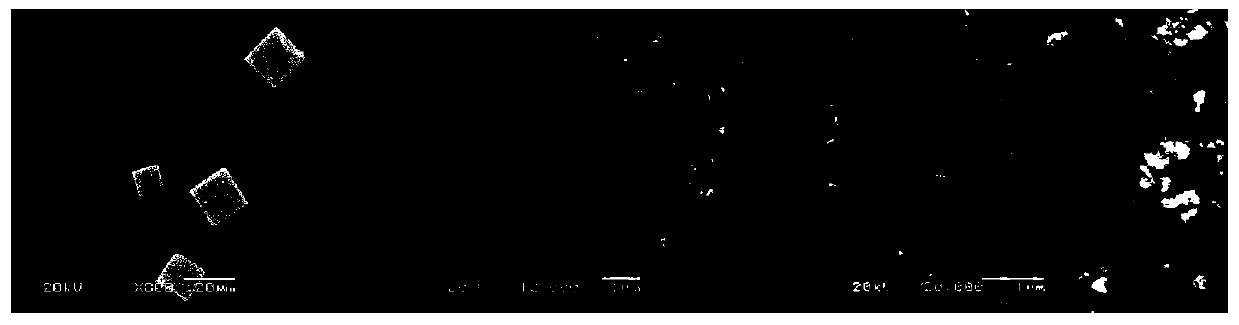

[0035] 3) The precursor is heated at 4° C. / min to 650° C. for 5 hours under an air atmosphere to obtain the cubic metal oxide composite material with a particle size of 5-50 μm, wherein the metal oxide nanosheets are 50-100 nm in size.

[0036] 4) Mix the nanocomposite material and electrode additives (conductive carbon, sodium carboxymethyl cellulose, ...

Embodiment 2

[0038] 1) Dissolve 0.75g zinc nitrate hexahydrate, 0.05g bismuth nitrate pentahydrate, 0.015g aluminum chloride in 50ml DMF, and dissolve 0.2g terephthalic acid, 1g PVP, 40μl TEA in another 50ml DMF.

[0039] 2) Slowly pour the latter solution into the former solution in step 1 and sonicate at 30°C for 15 minutes; the ultrasonic frequency is 30KHz, transfer the resulting mixed solution into a polytetrafluoroethylene liner with a steel shell, and react at 120°C for 8 hours; After cooling to room temperature, the product was separated by centrifugation, washed 3 times with ethanol, and dried in vacuum at 100°C for 12 hours;

[0040]3) The obtained precursor is heated up to 650° C. for 5 hours at 4° C. / min in an air atmosphere to obtain the cubic metal oxide composite material with a particle size of 5-50 μm, wherein the metal oxide nanosheets are 50-100 nm in size.

[0041] 4) Mix the nanocomposite material and electrode additives (conductive carbon, sodium carboxymethyl cellulo...

Embodiment 3

[0043] Other conditions are the same as in Example 1, except that the added stannous chloride dihydrate in step 1 is changed to 0.02g indium chloride.

[0044] The cycle test of the obtained product shows that after 160 cycles of charging and discharging, the specific capacity is 616.8mAh g-1, and the average Coulombic efficiency is 93.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com