Konjac cereal recombined rice beneficial for glucose homeostasis and preparation method thereof

A technology of reconstituted rice and steady state, applied in the field of food processing, can solve the problems of efficacy verification of recombinant rice products, lack of scientificity, rigor, ignoring the influence of glycemic index, etc., to delay the oxidation of lipids and other biological membranes. process, better hypoglycemic effect, better inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

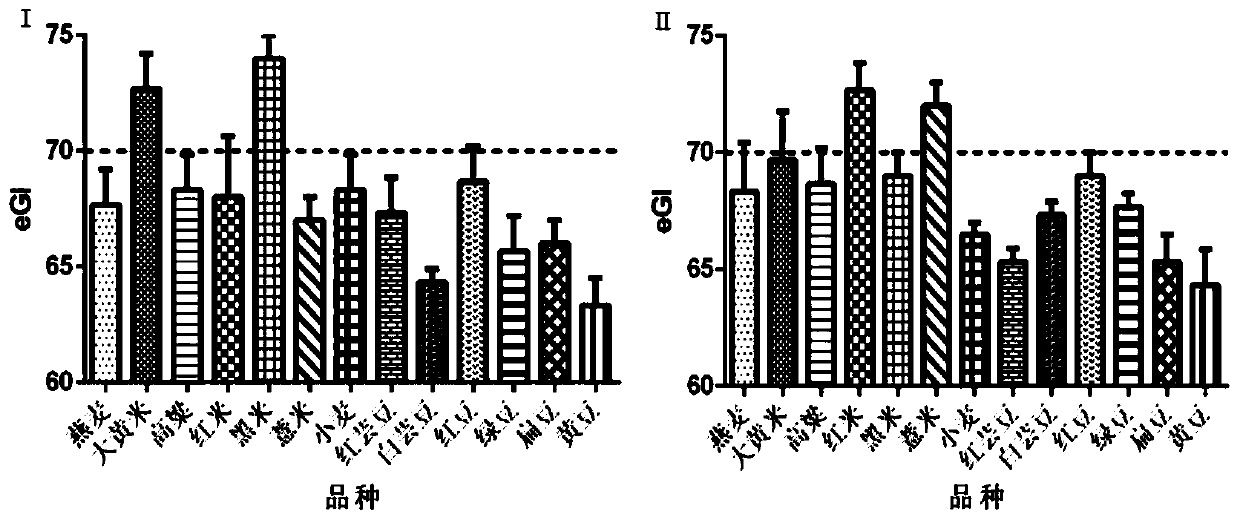

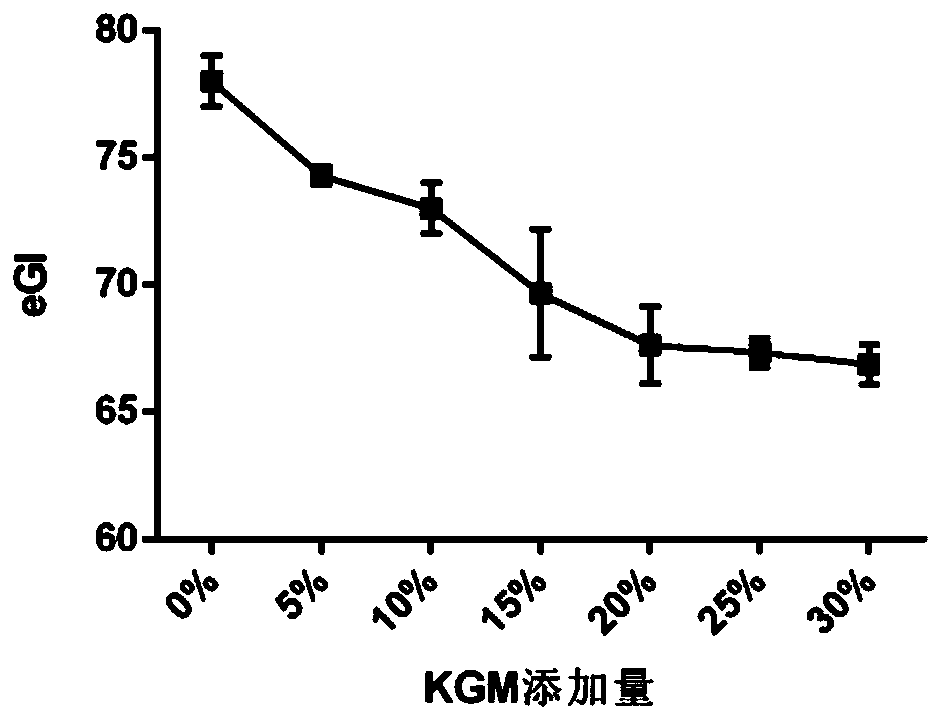

[0033] The screening of embodiment 1 konjac miscellaneous grains recombinant rice raw material

[0034] 1. Screening of recombinant rice starch matrix raw materials

[0035] According to the experimental analysis of the sensory and functional properties of commercially available konjac recombined rice, with the goal of improving the hardness, elasticity, and chewiness of recombined rice, reducing the glycemic index of recombined rice and making it have the function of improving the blood sugar homeostasis of diabetic organisms, the raw materials are considered Economical, product achievability and safe nutrition, through data analysis and comparison of material and nutritional components, preliminarily select black rice, barley, sorghum, red beans, wheat, mung beans, soybeans, lentils, red kidney beans, red rice, oats, White kidney beans and large yellow rice were used as starch substrates for follow-up studies.

[0036] All kinds of miscellaneous grain raw materials are crus...

Embodiment 2

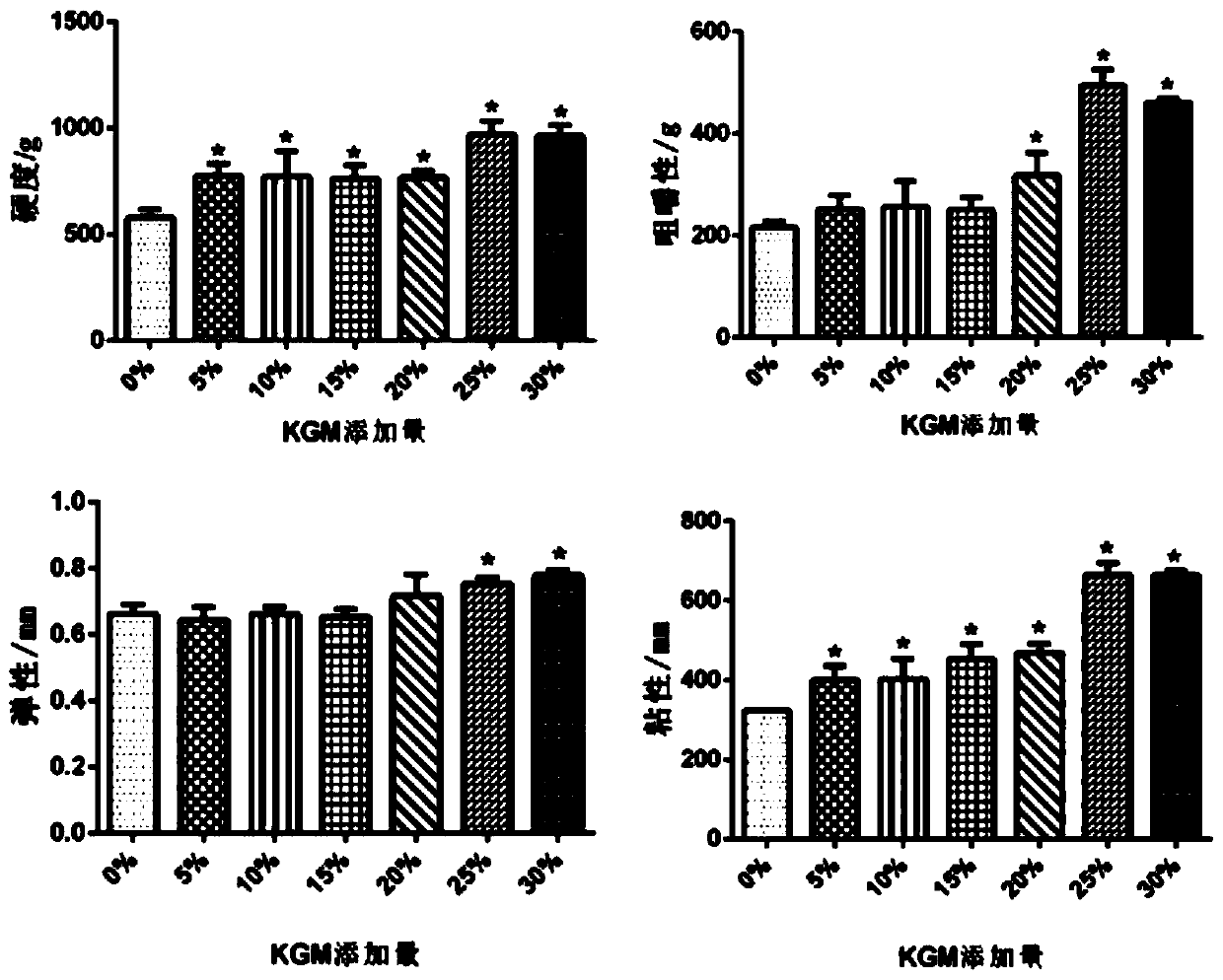

[0049] The groping of embodiment 2 preparation technology

[0050] 1. Determination of process parameters

[0051] Comprehensively considering the extrusion characteristics of the main raw materials and the viscosity characteristics of the powder mixing system, through the pre-production test, the process parameters are determined as follows: feeding rate 15kg / h, water flow rate of the extruder 20%, screw speed 150r / min, T2 cavity temperature 70°C, T3 cavity temperature 150°C, T4 cavity temperature 160°C, T5 cavity temperature 80°C, T6 cavity temperature 80°C, cutting speed 900rpm, 1.3mm 6-hole mold. Under the conditions of the production process, a recombined rice product with complete shape and uniform grains can be obtained.

[0052] 2. Control of product technical characteristics

[0053] The technical characteristics of the product, such as color, permeability, and particle fullness, can be regulated through technical means such as raw material selection, raw material m...

Embodiment 3

[0057] Embodiment 3 efficacy test

[0058] Test the efficacy of the product prepared in Example 1, adopt high-fat purified feed to raise combined intraperitoneal injection of streptozotocin to establish a type 2 diabetes rat model, and randomly divide it into a normal control group (CON) and a model control group according to fasting blood glucose (FBG) levels. group (MOD), natural rice (R) control group and 3 konjac recombinant rice dosage groups, 10 rats in each group.

[0059] CON: normal control group; MOD: diabetic control group; R: natural rice intervention group; KGM5%: konjac recombinant rice low-dose intervention group; KGM10%: konjac recombinant rice medium-dose intervention group; KGM15%: konjac recombinant rice high-dose intervention Group.

[0060] 1. The effect of the product on blood sugar indicators in type 2 diabetic rats

[0061] Fasting blood glucose results are shown in Table 2 and Figure 4 As shown, when the intervention reached the 30th day, compared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com