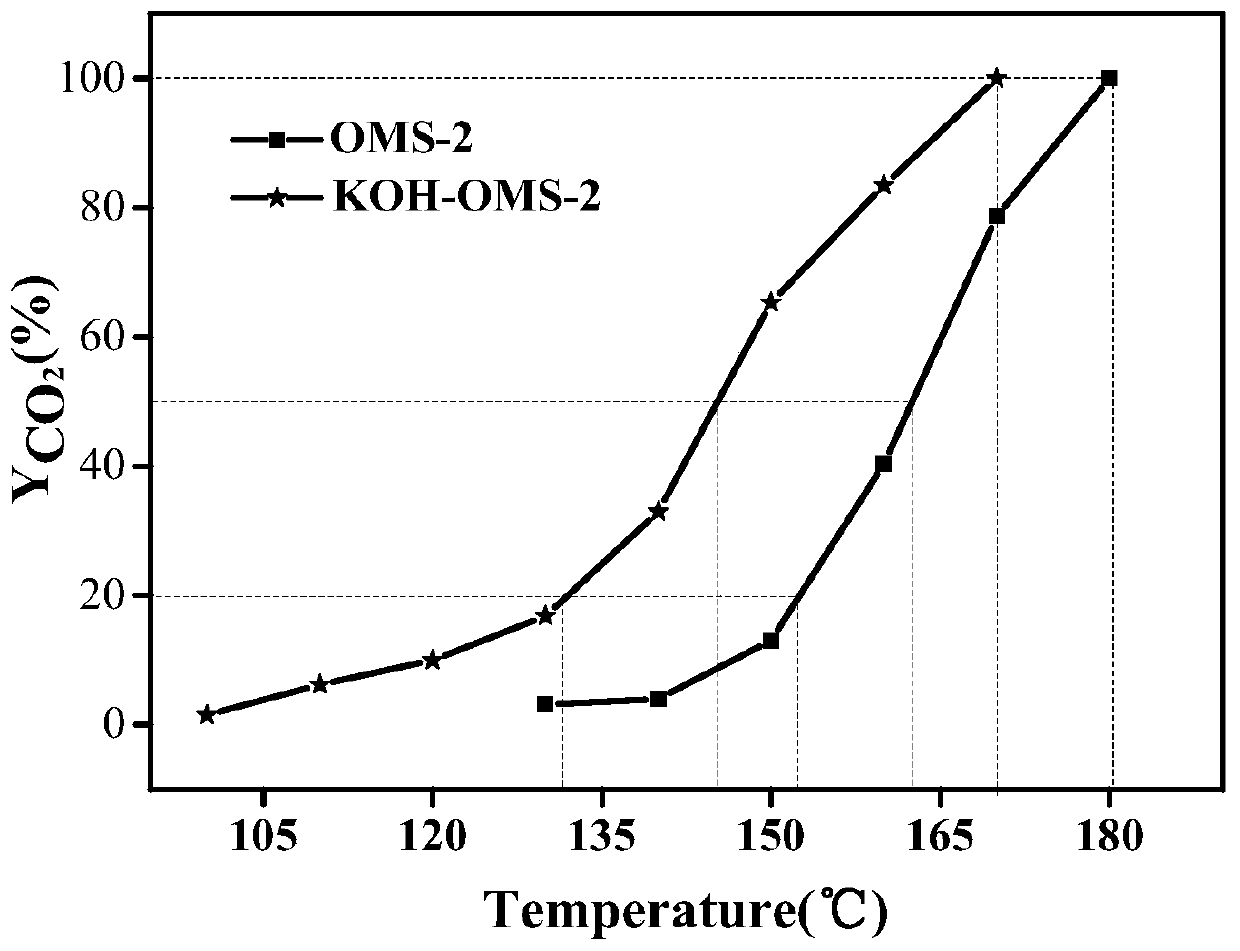

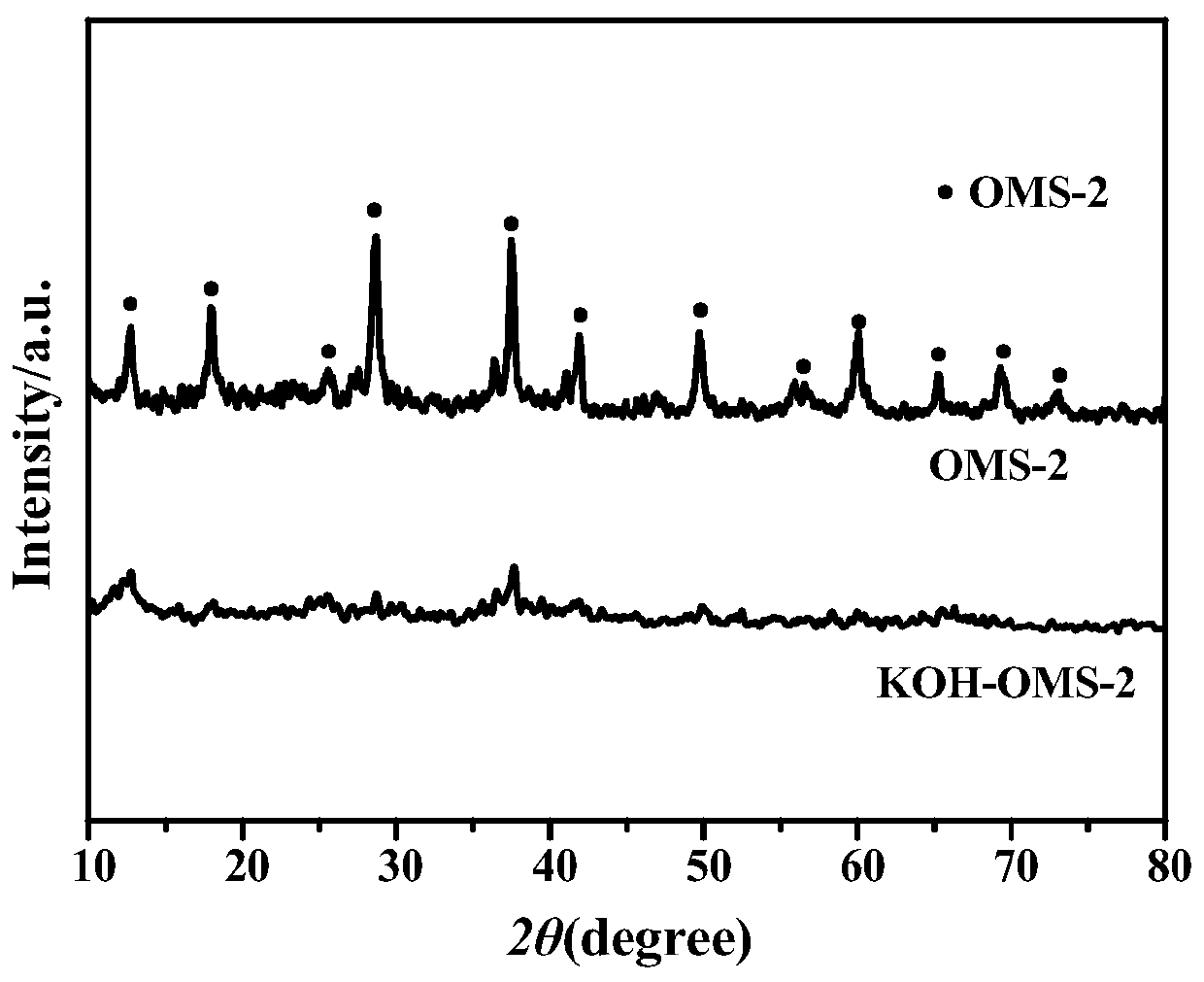

Potassium-doped MnO2 catalyst and preparation method thereof

A catalyst and potassium doping technology are applied in the field of potassium doped MnO2 catalyst and its preparation, which can solve the problems of complicated preparation process and incapability of doping, and achieve the effects of simple process, convenient operation and increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A potassium-doped MnO 2 The preparation method of catalyst, comprises the steps:

[0033] S1: Take 3.16g (0.02mol) of KMnO 4 Completely dissolved in 50 mL of distilled water to obtain KMnO 4 solution, take 2.1mL (0.02mol) of benzyl alcohol and add it dropwise to KMnO 4 In the solution, after the dropwise addition, stir and react in a water bath at 15°C for 24h, filter with suction, wash with water until neutral, then wash with ethanol, then wash with water until neutral, and dry at 110°C for 12h to obtain MnO 2 precursors, where MnO 2 Mn in the precursor 4+ Accounting for 92% of the total amount of Mn elements;

[0034] S2: Take 33.6g (0.6mol) KOH in a 50mL beaker, dissolve it in distilled water, transfer the KOH solution into a 100mL volumetric flask, dilute to the mark with distilled water, shake well, and prepare a 6M KOH solution. Measure 23mL of the prepared KOH solution in a 100mL round bottom flask, add 1g (11.5mmol) of the above MnO 2 The precursor was he...

Embodiment 2

[0036]A potassium-doped MnO 2 The preparation method of catalyst, comprises the steps:

[0037] S1: Take 3.16g (0.02mol) of KMnO 4 Completely dissolved in 50 mL of distilled water to obtain KMnO 4 solution, take 2.1mL (0.02mol) of benzyl alcohol and add it dropwise to KMnO 4 solution, after the dropwise addition, stirred and reacted in a water bath at 10°C for 24h, filtered with suction, washed with water until neutral, then washed with water until neutral, and dried at 110°C for 12h to obtain MnO 2 precursors, where MnO 2 Mn in the precursor 4+ Accounting for 92% of the total amount of Mn elements;

[0038] S2: Take 11.2g (0.2mol) KOH in a 50mL beaker, dissolve it in distilled water, transfer the KOH solution into a 100mL volumetric flask, dilute to the mark with distilled water, shake well, and prepare a 2M KOH solution. Measure 23mL of the prepared KOH solution in a 100mL round bottom flask, add 1g (11.5mmol) of the above MnO 2 Precursor, heated and refluxed for 12h,...

Embodiment 3

[0040] A potassium-doped MnO 2 The preparation method of catalyst, comprises the steps:

[0041] S1: Take 3.16g (0.02mol) of KMnO 4 Completely dissolved in 50 mL of distilled water to obtain KMnO 4 solution, take 1.05mL (0.001mol) of benzyl alcohol and add it dropwise to KMnO 4 In the solution, after the dropwise addition, stir the reaction in a water bath at 10°C for 20h, filter with suction, wash with water until neutral, then wash with ethanol, then wash with water until neutral, and dry at 120°C for 10h to obtain MnO 2 precursors, where MnO 2 Mn in the precursor 4+ Accounting for 90% of the total amount of Mn elements;

[0042] S2: Take 44.8g (0.8mol) KOH in a 50mL beaker, dissolve it in distilled water, transfer the KOH solution into a 100mL volumetric flask, dilute to the mark with distilled water, shake well, and prepare an 8M KOH solution. Measure 23mL of the prepared KOH solution in a 100mL round bottom flask, add 1g (11.5mmol) of the above MnO 2 Precursor, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com