Acid recovery and purification system for pickling waste liquid

A technology for pickling waste liquid and purification system, which is applied in the fields of metallurgical waste water treatment, chemical instruments and methods, special treatment targets, etc. The upper and lower forces on the membrane and the difference in concentration are different, the water distribution is uniform, and the floor space is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

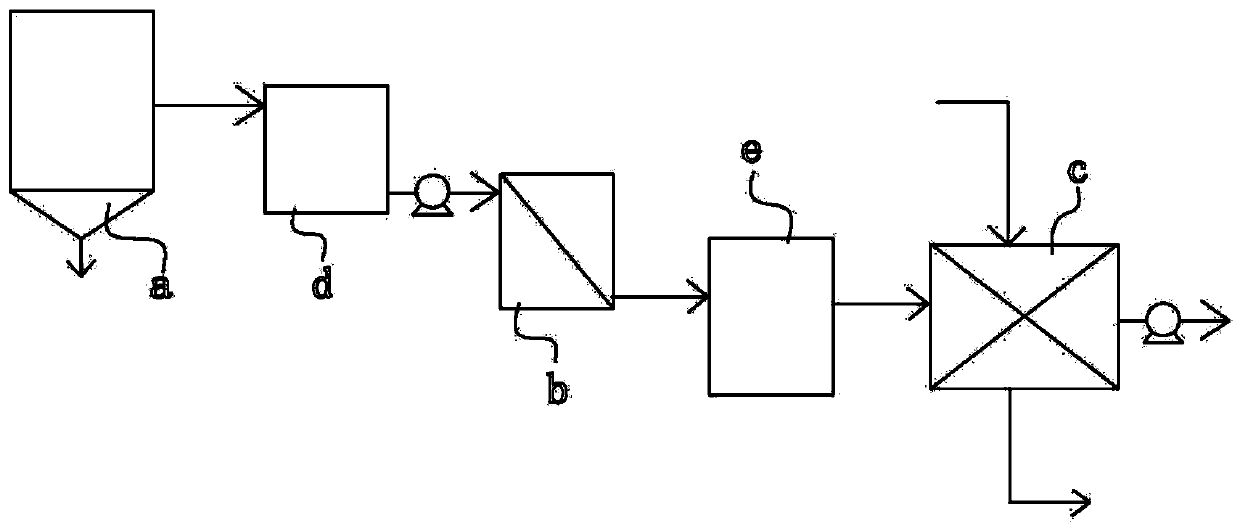

[0062] Example 1: Reference figure 1 , An acid recovery and purification system for pickling waste liquid. The system is used to treat acid-containing wastewater in the metal finishing industry. Such wastewater includes phosphoric acid (20-30%), sulfuric acid (5%), and nitric acid (1- 2%), aluminum: ≥75mg / L, chromium: ≥5mg / L, and nickel ≥6mg / L. The waste acid to be recycled in the system of the present invention is mainly phosphoric acid (weak acid). As we all know, the adsorption affinity of acid radical ions is The acidity is proportional to the strength of the acid. Strong acid ions are more electronegative and easier to be adsorbed by the resin, while weak acid ions are less electronegative and less likely to be adsorbed by the resin;

[0063] The pickling waste liquid flows through the waste acid settling device a, the first storage tank d, the filtering device b, the second storage tank e, and the ion exchange resin recovery device c in sequence;

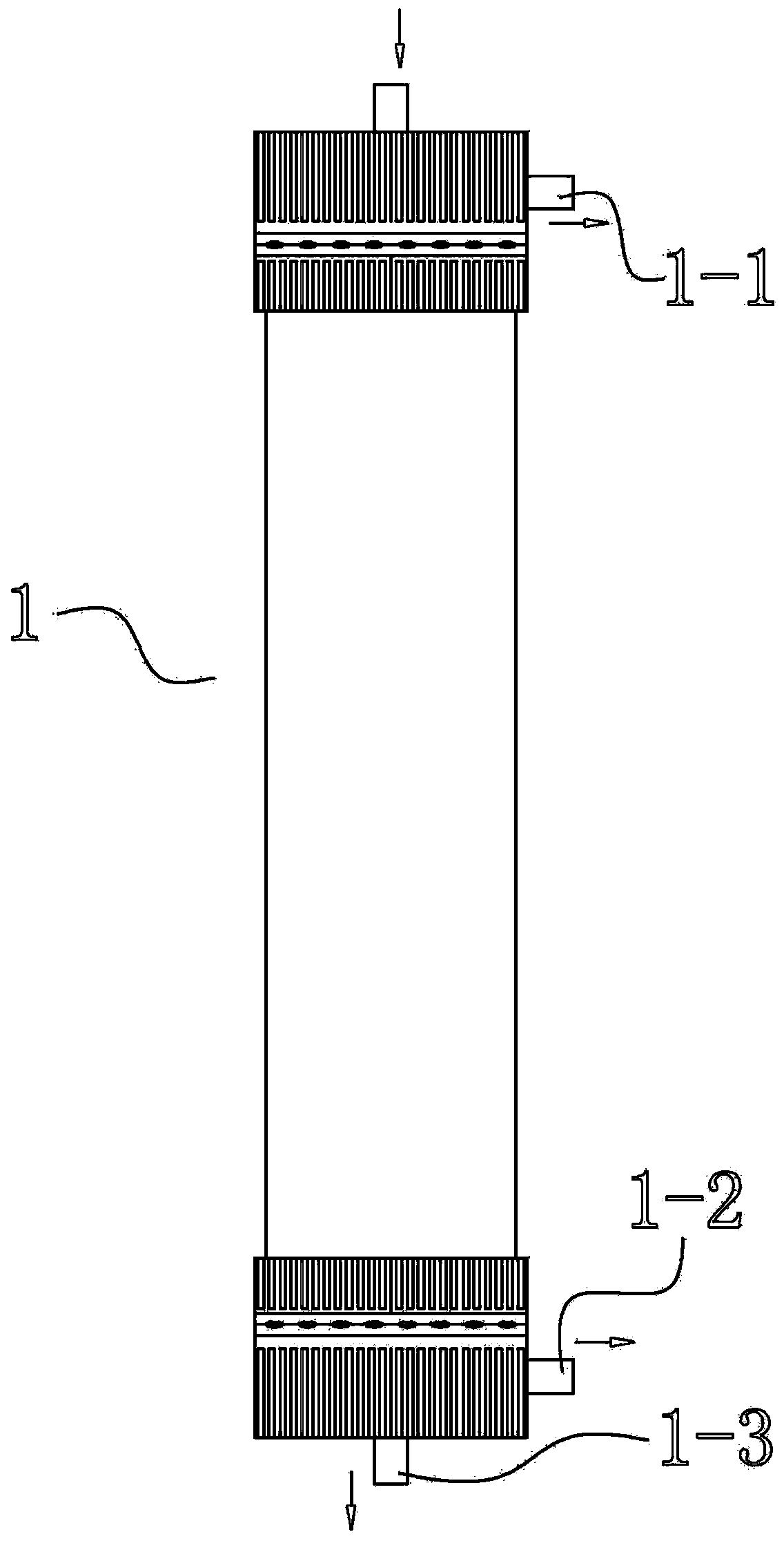

[0064] Among them, the was...

Embodiment 2

[0073] Example 2: Reference figure 1 , Figure 5 with Image 6 , An acid recovery and purification system for pickling waste liquid. The difference from embodiment 1 is that: the waste acid settling device a is provided with a detachable basket a-1, and the bottom surface of the basket a-1 A precipitation adsorption part a-2 with a porous structure is arranged at the location, and the precipitation adsorption part a-2 is composed of a plurality of precipitation adsorption plates a-2.1 with pores.

[0074] In actual use, the inside of the precipitation adsorption part a-2 formed by superimposing several pieces of the precipitation adsorption board a-2.1 is composed of staggered pore structure, and the pore structure is mainly composed of aluminum hydroxide, nickel hydroxide and chromium hydroxide. The sediment is easily adsorbed in the pores. At the same time, the interlaced pore structure supports each other so that the sediment is not easily desorbed from the sediment adsorption...

Embodiment 3

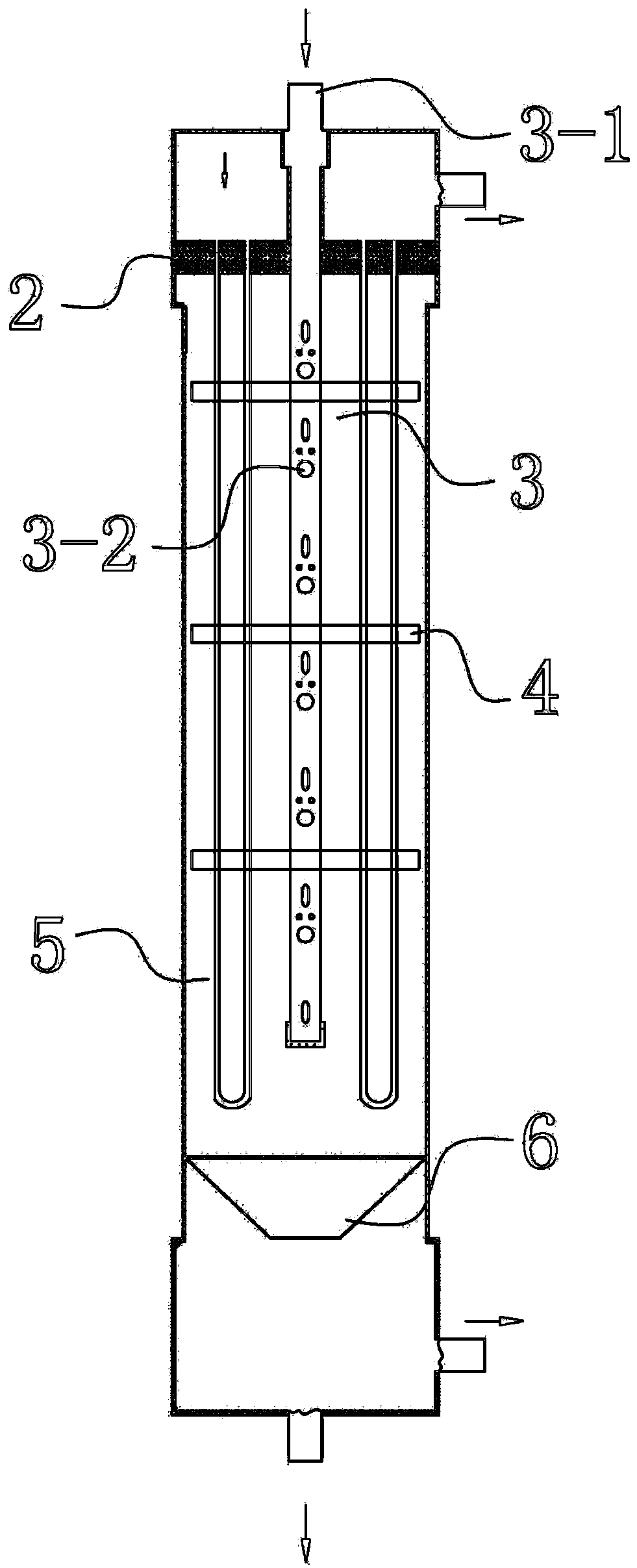

[0076] Example 3: Reference figure 1 , Figure 7 , Figure 8 with Picture 9 , An acid recovery and purification system for pickling waste liquid. The difference from Example 1 is that: the ion exchange resin recovery device c is provided with a plurality of speed increasing tubes c-1 at the inlet of the material liquid. The speed-increasing tube c-1 is composed of a condensing part c-1.1 and a speed-increasing port c-1.2 according to the flow direction of the material and liquid. The condensing part c-1.1 is a section of tube body whose inner diameter is gradually reduced according to the flow direction of the material and liquid. Small, the speed increasing port c-1.2 is in communication with the ion exchange resin recovery device c;

[0077] The material liquid outlet of the ion exchange resin recovery device c is provided with a plurality of pressure-increasing pipes c-2. The pressure-increasing pipe c-2 consists of a diffuser c-2.1 and a pressure-increasing port c in sequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com