Preparation method of diamond tool

A diamond tool and diamond technology, applied in the direction of improving process efficiency, metal material coating process, improving energy efficiency, etc., can solve the problems of time-consuming and long diamond particles, limiting diamond particle tools, diamond thermal damage, etc., to achieve efficiency and performance. Both, the process heat input is small, and the residual stress is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

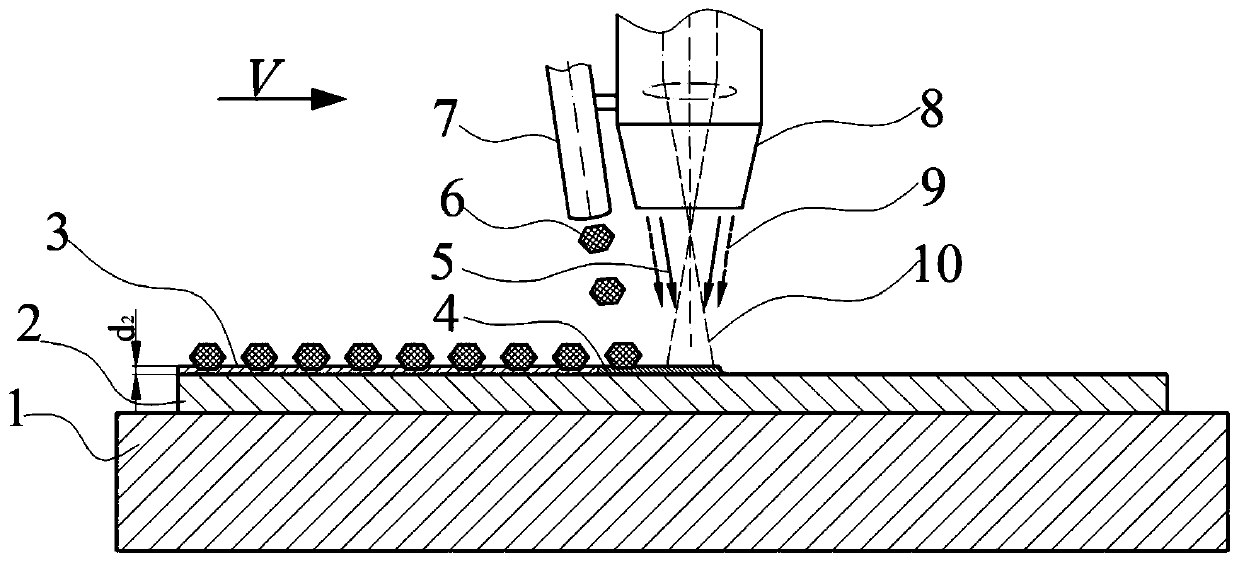

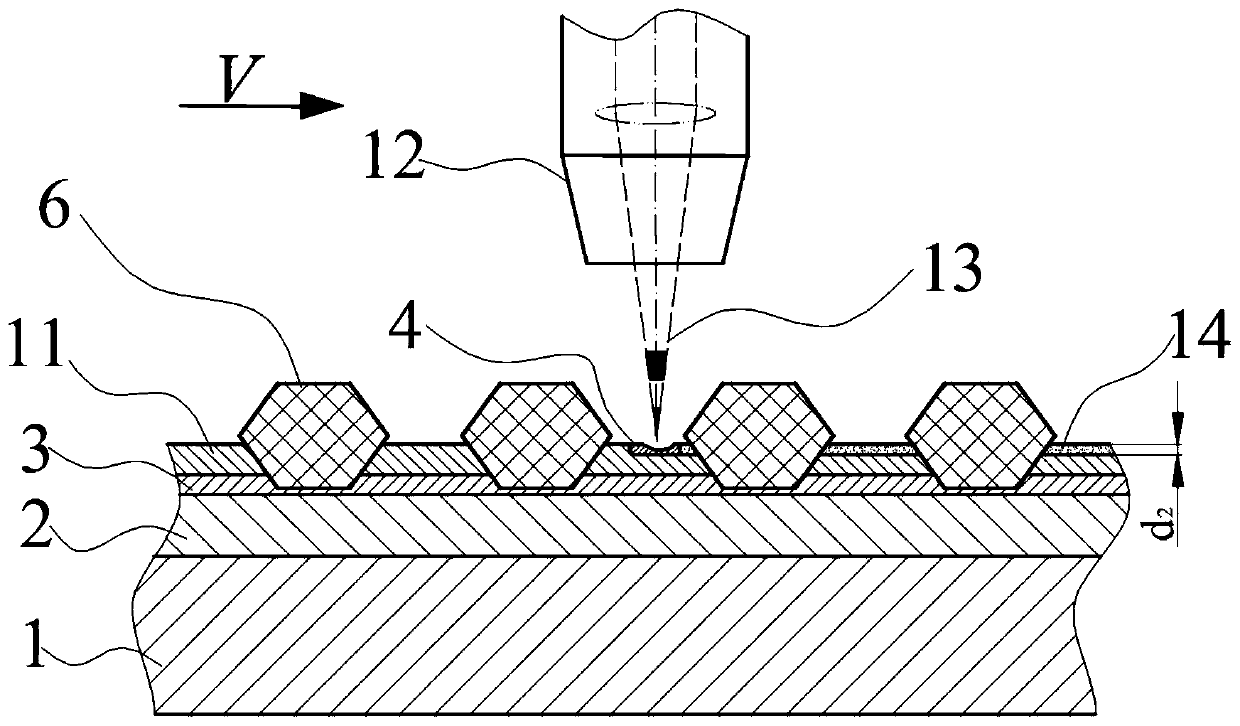

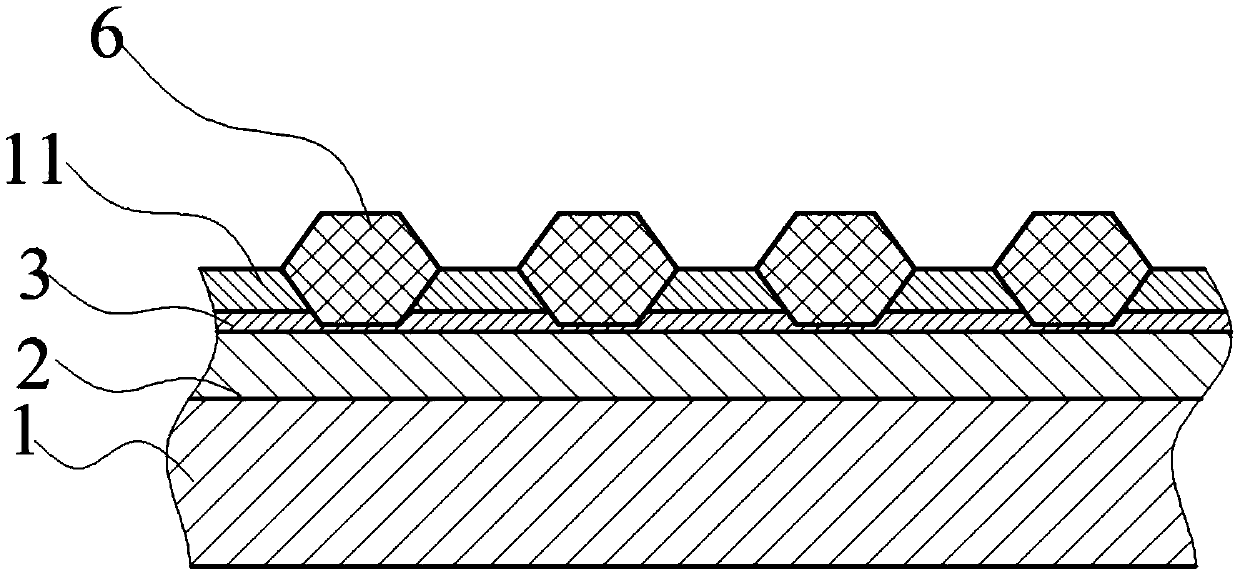

[0045] The following will be combined with Figure 1-3 And specific embodiments describe the technical solution of the present invention in detail.

[0046] like Figure 1-3 As shown, in the embodiment of the present invention, a diamond tool preparation method based on laser manufacturing technology includes the following steps.

[0047] Step 1, providing a substrate 1 of a diamond tool.

[0048] Optionally, the substrate 1 is 45 steel.

[0049] Step 2, providing diamond particles 6 .

[0050] Optionally, the diamond particles 6 are synthetic hexagonal diamonds with a size of 15-55 mesh.

[0051] Step 3, providing alloy powder.

[0052] Optionally, the size of the alloy powder is 200 mesh.

[0053] Step 4, providing a laser manufacturing system.

[0054] Optionally, the laser manufacturing system includes a high-power continuous laser, a short pulse laser, a first transmission fiber, a second transmission fiber, a first laser working head 8, a second laser working head...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap