Durable Zn-nSiO2 electroplated copper-nickel alloy super hydrophobic and oleophobic material

A superhydrophobic and oleophobic, zn-nsio2 technology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problems of poor durability, superhydrophobic materials only have superhydrophobicity, and do not have superoleophobic properties, etc., to achieve faster The effect of nucleation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

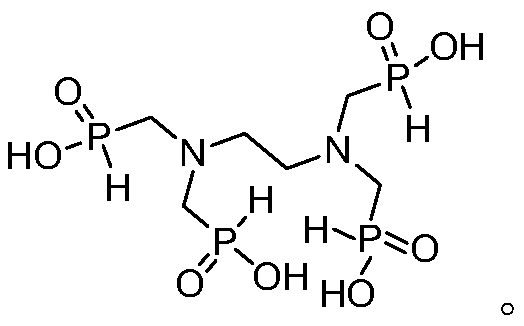

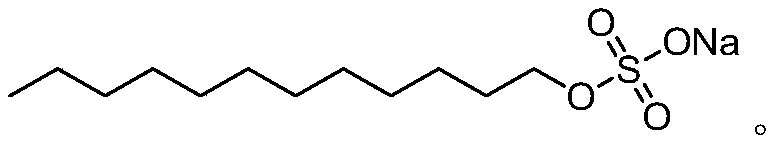

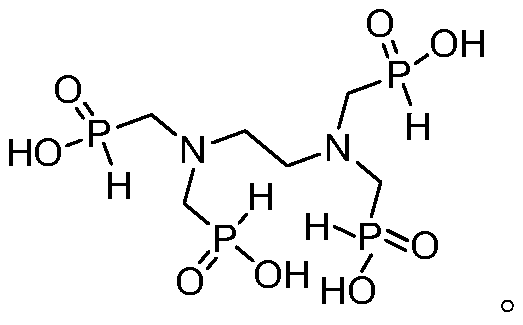

[0023] In order to achieve the above object, the present invention provides the following technical solutions: a durable Zn-nSiO 2 The electroplated copper-nickel alloy superhydrophobic and oleophobic material comprises the following raw materials in proportions by weight: 0.4-1 part of copper(II) chloride dihydrate, 0.5-1.5 part of nickel nitrate hexahydrate, 4-7 parts of diethylene dichloride Sodium amine tetramethylene phosphate, 0.1-0.5 parts of sodium dodecyl sulfate, 15-20 parts of mixed plating solution, 20-25 parts of electrolytic purification solution, 45-60 parts of electrode activation solution, copper (II) chloride dihydrate The molecular formula is CuCl 2 2H 2 O, where CuCl 2 The mass fraction is 74.1-76.2%, and the molecular formula of nickel nitrate hexahydrate is Ni(NO 3 ) 2 ·6H 2 O, where Ni(NO 3 ) 2 The mass fraction is 59.1-61.4%. Sodium p-ethylenediaminetetramethylene phosphate is a metal complexing agent with a content of 95.2-97.5%. Its structural ...

Embodiment 1

[0029] (1) Preparation of Cu-Ni alloy by galvanostatic deposition method: N 2 Remove the air, and add 200mL of distilled water, then weigh 0.4 parts of copper (II) chloride dihydrate, 0.5 parts of nickel nitrate hexahydrate and 4 parts of sodium p-ethylenediaminetetramethylene phosphate into the three-necked flask, and stir for 1 -1.5h, to dissolve the solid completely, then weigh 0.1 part of sodium lauryl sulfate and add it to the three-necked bottle, after stirring evenly, slowly add 0.6mol / L NaOH solution dropwise to the three-necked bottle to adjust the three-necked bottle When the pH of the inner solution reaches 4-5, insert electrodes from the left and right mouths of the three-necked bottle, place the three-necked bottle in a constant temperature water bath and heat it to 45-50°C, and start electrodeposition. Through continuous nucleation, Cu- The number of Ni crystal nuclei increases with the increase of electrolysis time, and the nuclei produced continue to nucleate a...

Embodiment 2

[0032] (1) Preparation of Cu-Ni alloy by galvanostatic deposition method: N 2 Remove the air, and add 200mL of distilled water, then weigh 0.5 parts of copper (II) chloride dihydrate, 1.3 parts of nickel nitrate hexahydrate and 5 parts of sodium p-ethylenediamine tetramethylene phosphate into the three-necked flask, and stir for 1 -1.5h, to dissolve the solid completely, then weigh 0.2 parts of sodium lauryl sulfate and add it to the three-necked bottle. After stirring evenly, slowly add 0.6mol / L NaOH solution dropwise to the three-necked bottle to adjust the When the pH of the inner solution reaches 4-5, insert electrodes from the left and right mouths of the three-necked bottle, place the three-necked bottle in a constant temperature water bath and heat it to 45-50°C, and start electrodeposition. Through continuous nucleation, Cu- The number of Ni crystal nuclei increases with the increase of electrolysis time, and the nuclei produced continue to nucleate and grow under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com