High-efficiency thermally-conductive graphene far infrared heating film and preparation method thereof

A technology of far-infrared heating film and thermally conductive graphite, used in electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of low heating rate, high energy consumption, slow thermal conductivity, etc., to reduce resistance and improve conversion. Efficiency, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

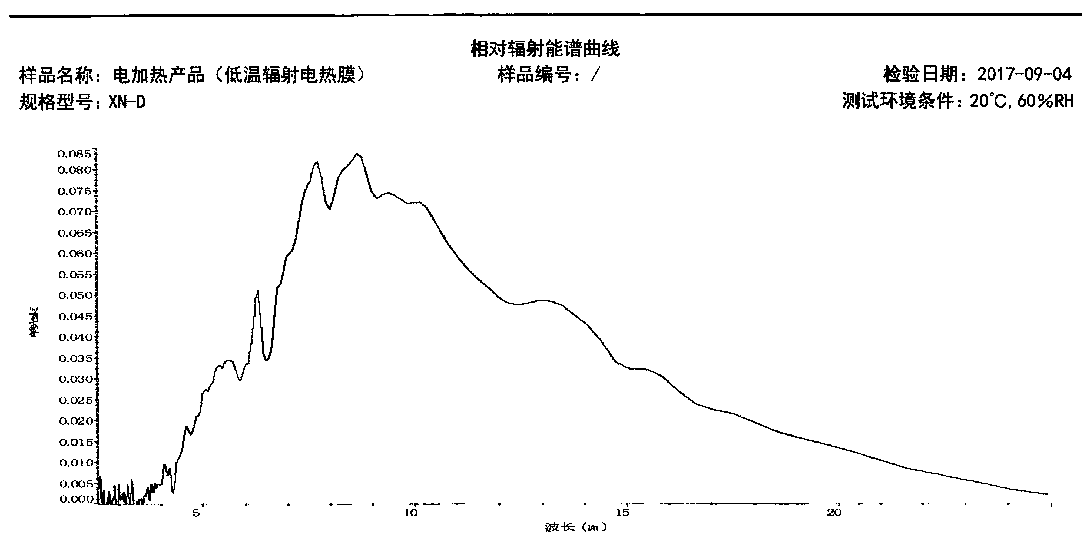

Image

Examples

Embodiment 1

[0033] A high-efficiency heat-conducting graphene far-infrared heating film is composed of a conductive paste layer and an insulating substrate, and the parts by weight of each component forming the conductive paste layer are:

[0034] Hydrotalcite modified graphene 50 parts

[0035] Water glass 45 parts

[0036] Terpineol 40 parts

[0037] 20 parts of water-based polyurethane

[0038] 5 parts ethyl cellulose

[0039] Dispersant 6 parts

[0040] Silicone oil 15 parts

[0041] 40 parts of water.

[0042] A method for preparing an efficient heat-conducting graphene far-infrared heating film, comprising the following steps:

[0043] (1) Preparation of hydrotalcite-modified graphene:

[0044] S1. Add graphite powder into the ball mill tank, pour carbon dioxide gas into the ball mill tank to remove the air in the tank, and make the pressure in the tank reach 1.2Mpa, and perform ball milling reaction to obtain carboxylated graphene, and prepare the concentration with deionize...

Embodiment 2

[0051] A high-efficiency heat-conducting graphene far-infrared heating film is composed of a conductive paste layer and an insulating substrate, and the parts by weight of each component forming the conductive paste layer are:

[0052] Hydrotalcite modified graphene 6 parts

[0053] 30 parts of water glass

[0054] Terpineol 30 parts

[0055] Tetrabutyl titanate 10 parts

[0056] 2 parts ethyl cellulose

[0057] Dispersant 4 parts

[0058] Silicone oil 5 parts

[0059] 25 parts of water.

[0060] A method for preparing an efficient heat-conducting graphene far-infrared heating film, comprising the following steps:

[0061] (1) Preparation of hydrotalcite-modified graphene:

[0062] S1. Add graphite powder into the ball milling tank, pour carbon dioxide gas into the ball milling tank to remove the air in the tank, and make the pressure in the tank reach 0.8Mpa, and perform ball milling reaction to obtain carboxylated graphene, and prepare the concentration with deionized w...

Embodiment 3

[0069] A high-efficiency heat-conducting graphene far-infrared heating film is composed of a conductive paste layer and an insulating substrate, and the parts by weight of each component forming the conductive paste layer are:

[0070] Hydrotalcite modified graphene 30 parts

[0071] 40 parts of water glass

[0072] Terpineol 35 parts

[0073] Lipid 15 parts

[0074] 4 parts ethyl cellulose

[0075] Dispersant 5 parts

[0076] Silicone oil 7 parts

[0077] 30 parts of water.

[0078] A method for preparing an efficient heat-conducting graphene far-infrared heating film, comprising the following steps:

[0079] (1) Preparation of hydrotalcite-modified graphene:

[0080] S1, graphite powder is added in the ball mill tank, and carbon dioxide gas is charged into the ball mill tank to get rid of the air in the tank, and the pressure in the tank reaches 1Mpa, and the ball mill reaction is carried out to obtain carboxylated graphene, and the concentration is prepared with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com