Grafting-type ionic liquid polyimide film, preparation method and application of film

A technology of polyimide membrane and ionic liquid, which is applied in the field of membrane separation, can solve the problems of poor mutual solubility, easy rupture and easy loss of membrane liquid, etc., to improve permeation flux, increase plasticizing pressure point and service life , The effect of increasing penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

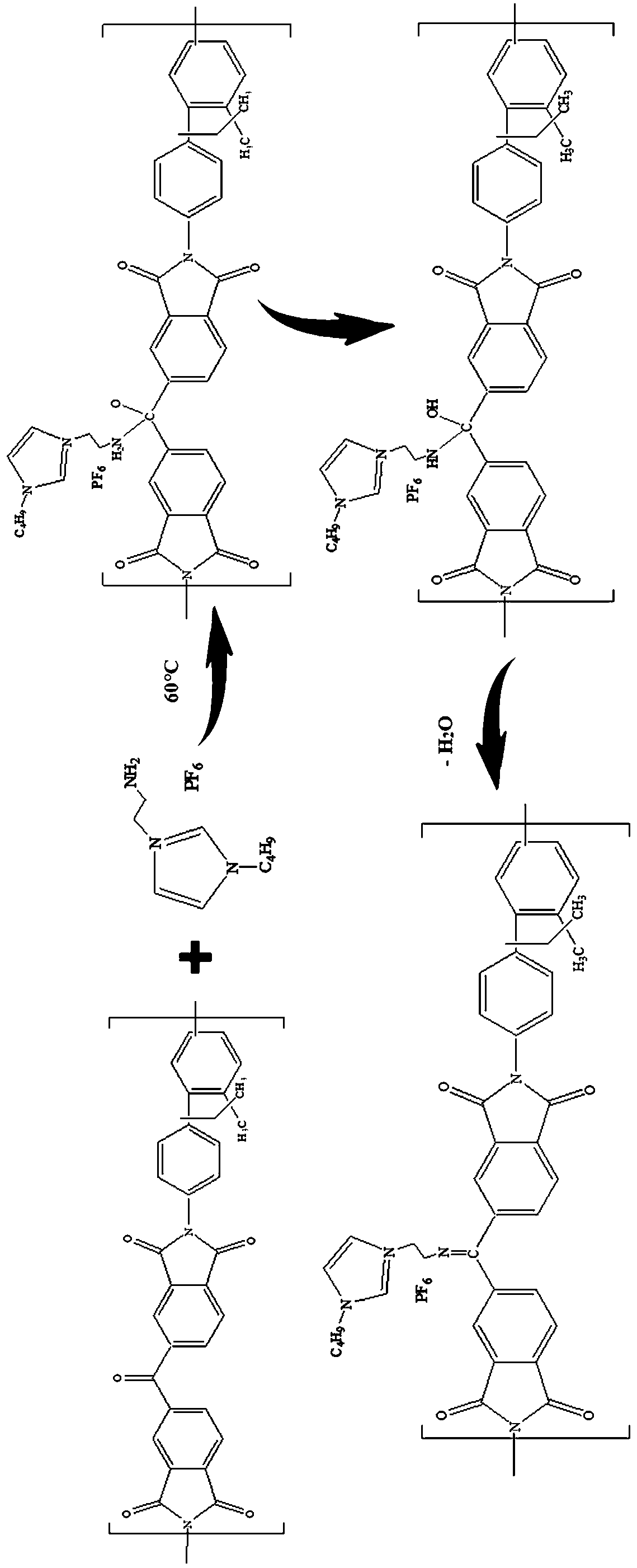

[0038] A method for preparing a grafted ionic liquid polyimide membrane, the method comprising the following steps:

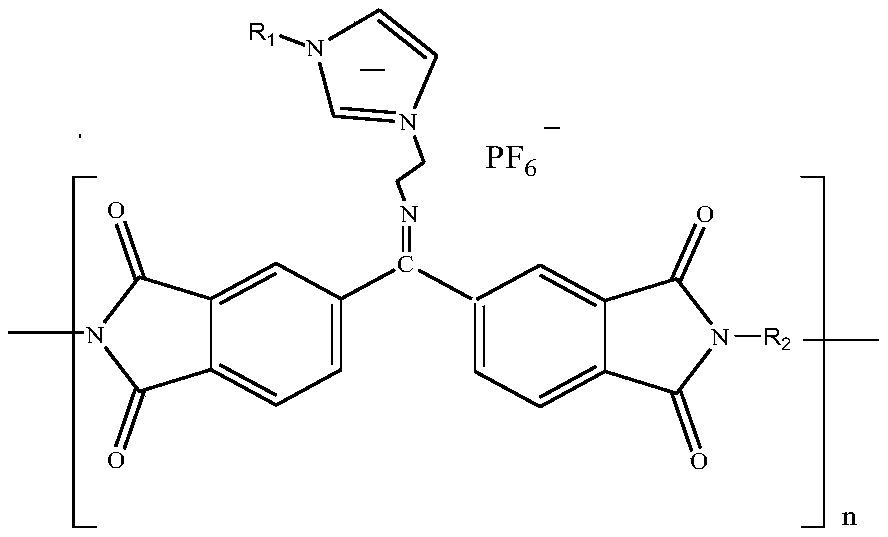

[0039] (1) Polyimide grafting: Add the aminated functional ionic liquid to the casting solution formed by polyimide, heat and stir in a water bath, and the aminated functional ionic liquid passes through the characteristic structure of the Schiff base to The base form is grafted on the polymer main chain to obtain an aminated casting solution;

[0040] (2) Preparation of grafted ionic liquid polyimide film: the aminated casting solution in step (1) is scraped and coated to form a film, and the solvent evaporation method is used to obtain a modified film, which is dried to solidify the film, and then After freezing, the membrane was peeled off to obtain a grafted ionic liquid polyimide membrane.

[0041] The thickness of the film is generally controlled within the range of 25 μm ± 4 μm when scraping to form a film.

[0042] Wherein, the preparation method of s...

Embodiment 1

[0059] Take a 250mL or 500mL three-necked round-bottom flask, weigh ethylbromoethylamine hydrobromide and N-butylimidazole at a ratio of 1:1.125, heat in an oil bath, and reflux ethanol for 22-24 hours, evaporate the obtained product to remove ethanol , to obtain a viscous liquid, pour it into a flat-bottomed flask, put it in a vacuum drying oven, and dry it at 80°C for 4 to 6 hours to obtain the intermediate 1-(2-aminoethyl)-3-butylimidazolium bromide . Then, add equimolar KOH to the intermediate, put the product in a vacuum drying oven for 12h to 24h, add an appropriate amount of ethanol, stir and dissolve, and generate a large amount of white solid KBr, remove the impurity KBr, and obtain aminoethyl Butylimidazole Hydrobromide. Finally, the obtained product is subjected to ion exchange reaction with KPF6. After the two were dissolved in ethanol, they were continuously reacted in a water bath at 66°C for 18-20 hours and then taken out. Vacuum filtration removes the genera...

Embodiment 2

[0063] The aminated functional ionic liquid prepared in Example 1 was used.

[0064] First dissolve 10g of polyimide in 90g of N-methylpyrrolidone solvent, heat and stir at 60°C for 8h, then add 0.8g of 1-aminoethyl-3-butylimidazole hexafluorophosphate, continue heating and stirring for 12h, and After the formed casting solution was degassed at room temperature for 12 hours, the casting solution was poured onto a horizontal glass plate and scraped to form a film. Put the glass plate in a vacuum drying oven, volatilize the solvent and water at 60°C to solidify the film, take it out and place it in a -4°C freezer for 15 to 30 minutes, and scrape off the film carefully to obtain the grafted ionic liquid polymer. imide film.

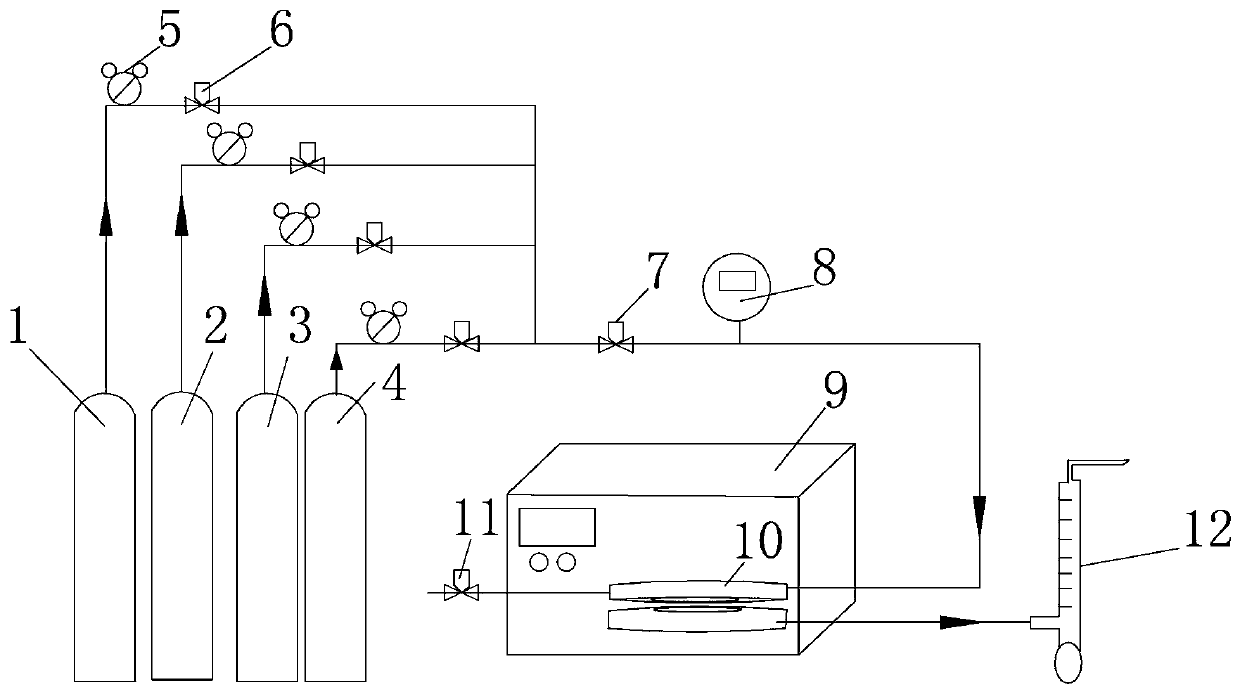

[0065] Under the test conditions of 0.1MPa and 30℃, the permeation flux of carbon dioxide increased from 5.28Barrer to 10.01Barrer, CO 2 / N 2 Selectivity increased from 21.9 to 84.9, CO 2 / CH 4 Selectivity increased from 24.1 to 44.5, CO 2 / O 2 Select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com