Surface modification method and device for third-generation semiconductor material in oxygen-enriched environment

A surface modification and semiconductor technology, which is applied in the direction of welding/cutting media/materials, welding media, laser welding equipment, etc., can solve the problem that the scratches on the surface of single crystal cutting sheets cannot be directly applied, and the surface precision processing technology is complex and difficult to complete Targeted surface modification and other issues, to achieve time and economic cost advantages, improve surface and sub-surface defects, and solve the effect of difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

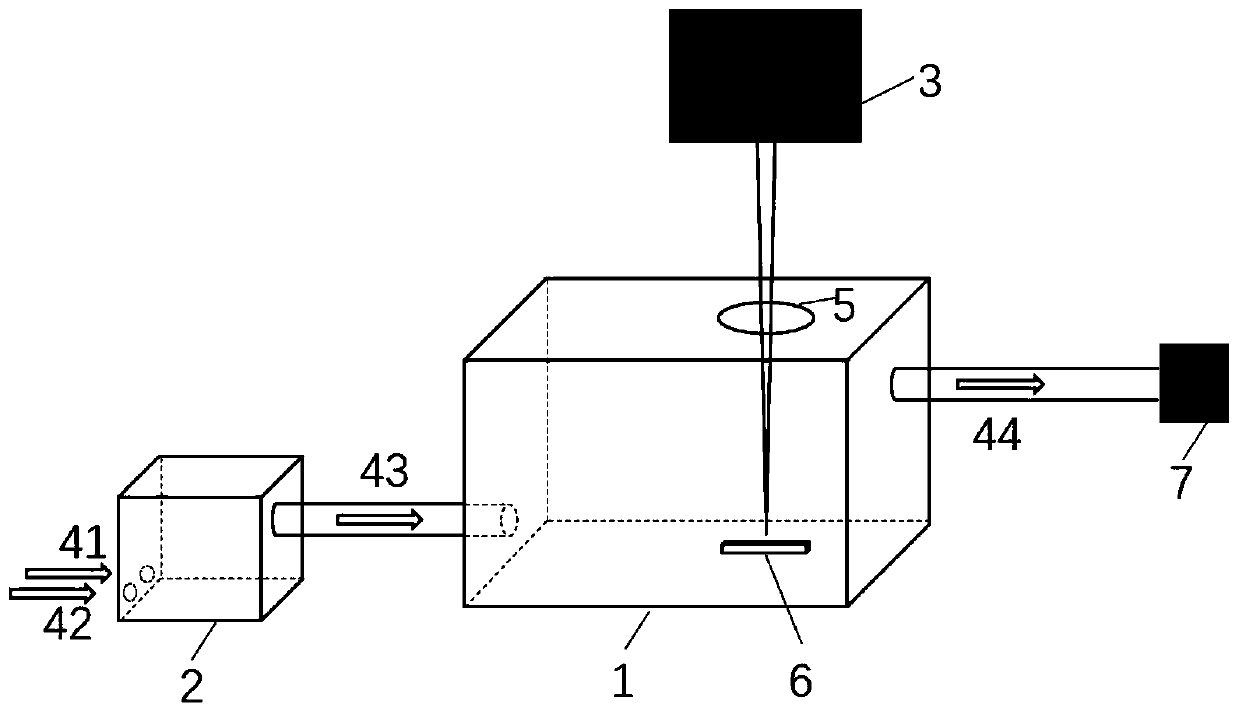

[0029] figure 1 It is a schematic diagram of the construction device of the oxygen-enriched environment of the present invention. The device for constructing the oxygen-enriched environment includes an oxygen-enriched container 1, a gas mixing chamber 2, a laser processing device and a vacuum pump 7, is the flow direction of the gas, the gas mixing chamber 2 is connected with the oxygen-enriched container 1 through pipelines, the laser processing device includes a laser emitter 3 and a workbench, and the laser generated by the laser emitter 3 is emitted from the oxygen-enriched container 1 is incident from above; the oxygen-enriched container 1 is fixed on the workbench of the laser processing device, and an opening 5 is arranged on the upper surface of the oxygen-enriched container 1, and the opening 5 is covered with a U-shaped rubber sealing ring Sealed with quartz glass, the gas mixing chamber 2 is provided with an oxygen content detector, which can be read from the outs...

Embodiment 2

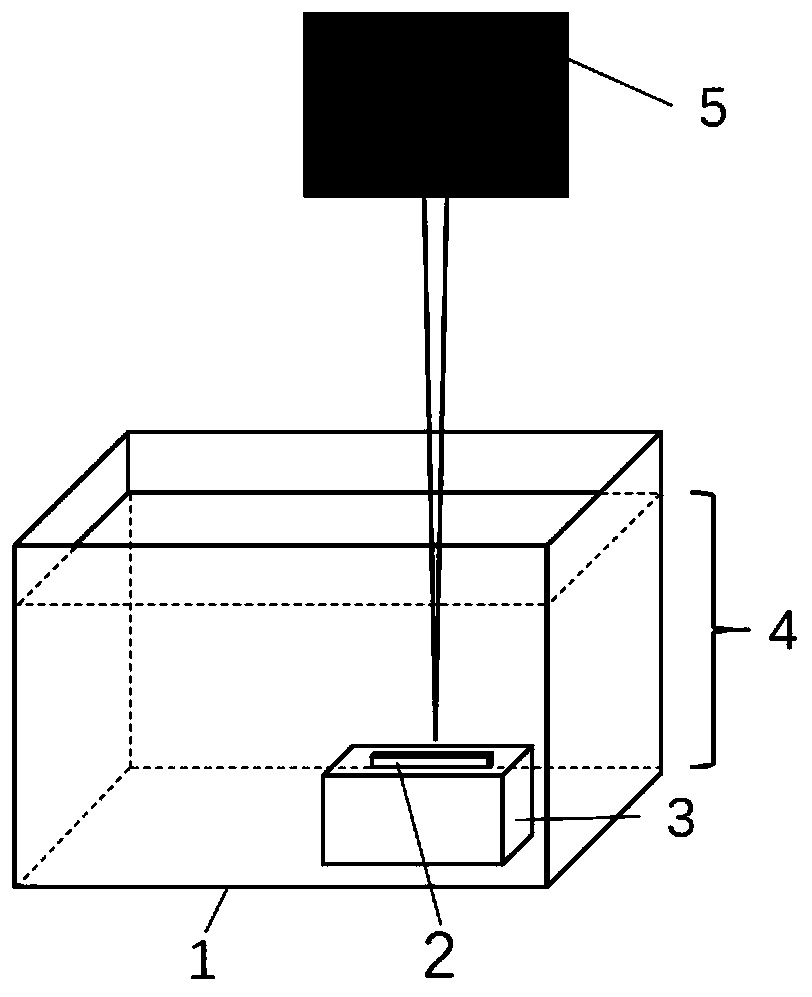

[0032] figure 2 It is a schematic diagram of a device for providing a liquid environment with high oxidation activity in Example 3 of the present invention. The device for constructing the oxygen-enriched environment includes an oxygen-enriched container 1 , a fixture 3 and a laser emitter 5 . Clamp the semiconductor material 2 (SiC, GaN, Si or GaAs) to be processed on the fixture 3, then place it in the oxygen-enriched container 1, and then add a transparent solution 4 with high oxidation activity (30% hydrogen peroxide aqueous solution) until the liquid level of the solution is 5-10 mm above the upper surface of the SiC material to be processed. The oxygen-enriched container 1 is fixed on the working platform of the laser processing device, and the height of the working platform is adjusted so that the laser beam passes through the transparent solution 4 with high oxidation activity and focuses on the upper surface of the semiconductor material 2 to be processed. Select t...

Embodiment 3

[0034] Indium sulfide ceramic materials will be oxidized when laser modification is carried out in the atmospheric environment. Place the indium sulfide ceramic material in a device with a high oxidation activity environment, and control the oxygen content in the processing atmosphere environment will certainly be able to adjust the degree of oxidation during processing. , so as to adjust the properties of the modified surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com