Method and breeding sewage treatment system for treating breeding sewage through pulverized fuel ash

A technology for aquaculture sewage and treatment system, which is applied in water/sewage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of use limitation, harsh synthesis conditions, and difficulty in dissolving, so as to reduce COD. Value and chromaticity, the effect of reducing sewage treatment costs and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below through specific embodiments.

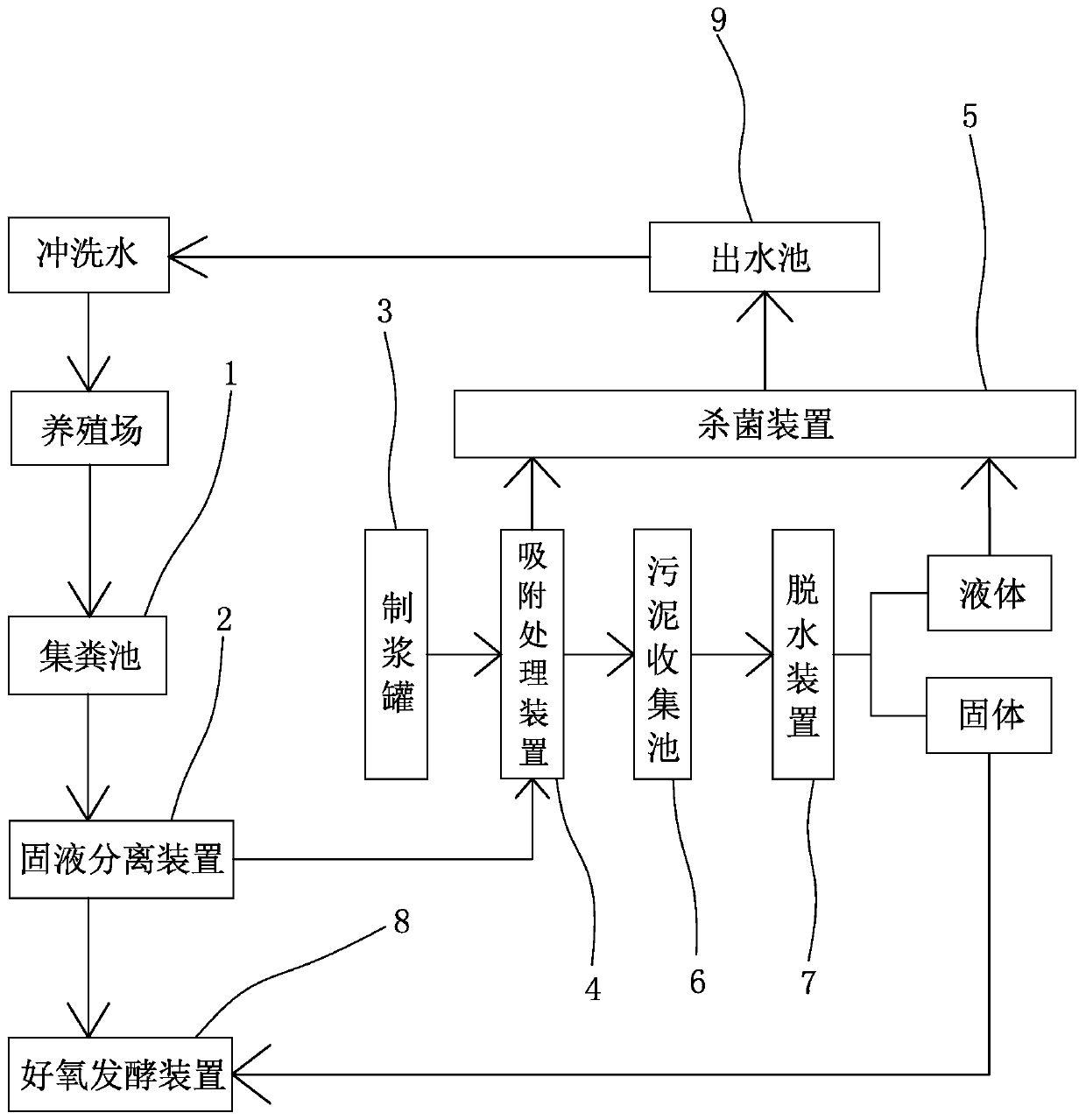

[0042] refer to Figure 1 to Figure 9 As shown, a breeding sewage treatment system utilizing fly ash to treat breeding sewage includes a septic tank 1, a solid-liquid separation device 2, a pulping tank 3, an adsorption treatment device 4, a sterilization device 5, a sludge collection tank 6, Dehydration device 7, aerobic fermentation device 8 and water outlet tank 9.

[0043] The septic tank 1 is used to collect the excrement produced by the farm.

[0044] The solid-liquid separation device 2 is connected to the septic tank 1, and performs solid-liquid separation on the feces collected in the septic tank 1 to obtain separation liquid and solid waste. The solid-liquid separation device 2 is a solid-liquid separation device commonly used in sewage treatment systems , and its specific structure will not be further described here.

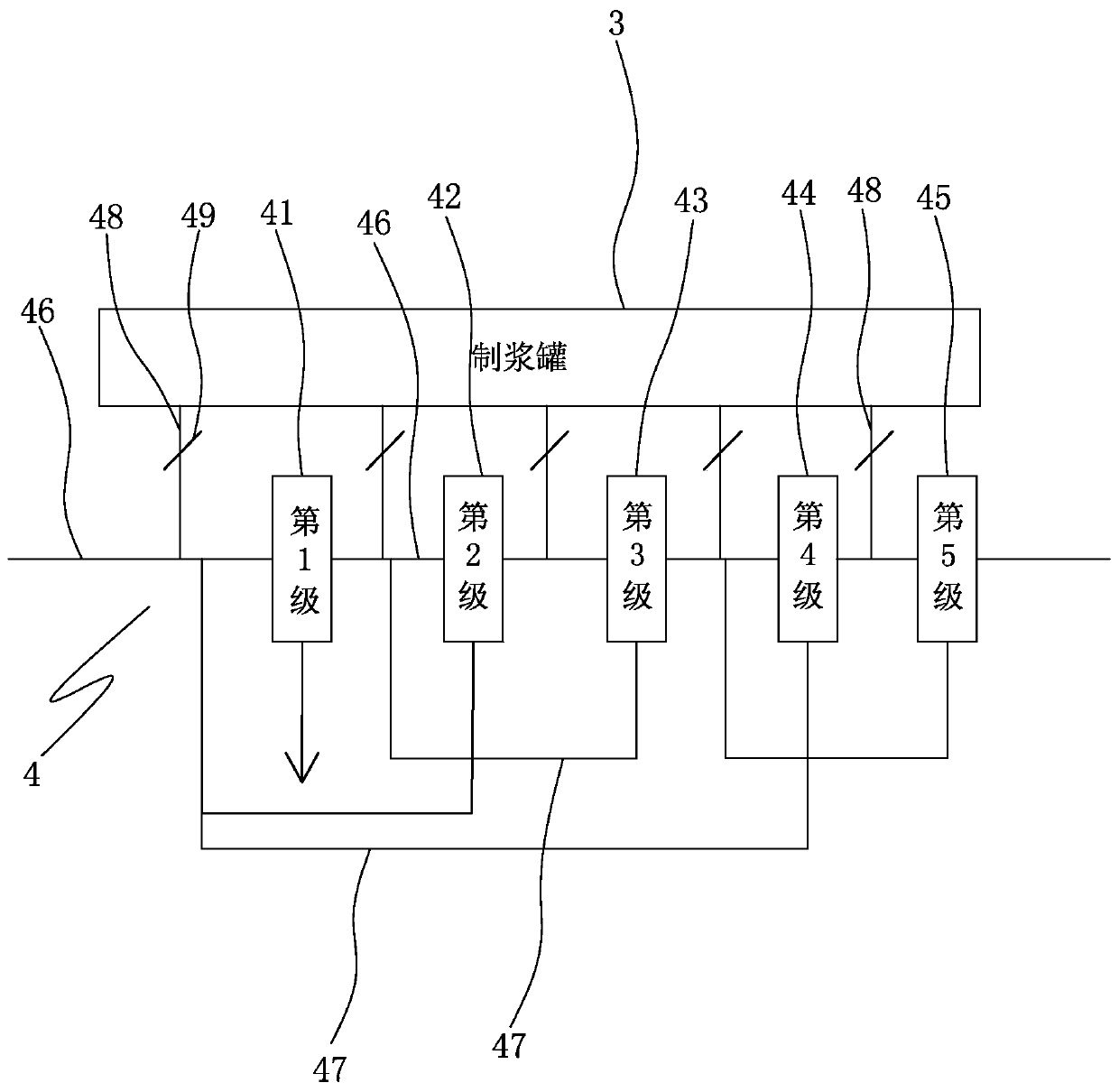

[0045]The pulping tank 3 is used to prepare fly ash s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com