Method for preparing 1,2-polybutadiene rubber toughened modified polylactic acid

A technology of polybutadiene rubber and polybutadiene, which is applied in the field of rubber toughening modified plastics, can solve problems such as strength decline, and achieve the effects of improving toughness, reducing the magnitude of strength decline, and high motion matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

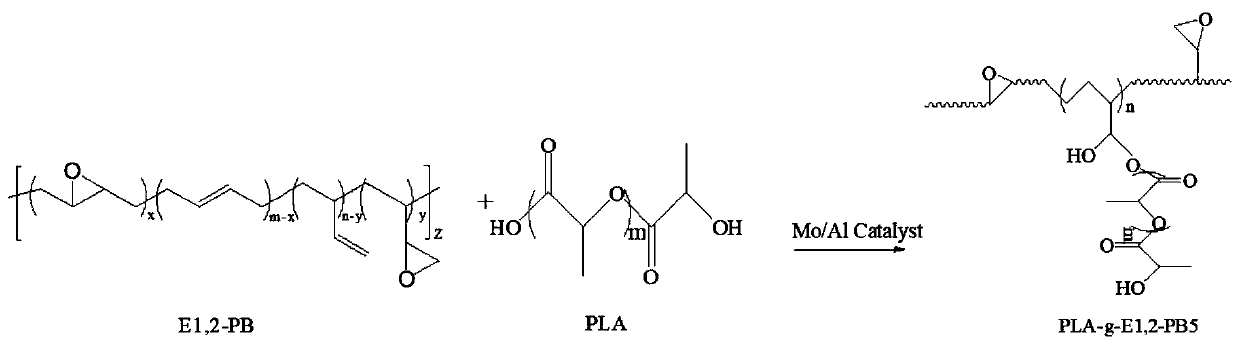

[0032] The invention provides a preparation method of polylactic acid toughened and modified by 1,2-polybutadiene rubber. First, 1,2 polybutadiene (E1,2-PB) with different epoxy degrees is prepared, and then E1,2-PB with different epoxy degrees is dissolved in the lactide polymerization system. During the in-situ polymerization of lactide (generation of polylactide (PLA), the grafting reaction with E1,2-PB occurs simultaneously. , generate PLA-g-E1,2-PB. Its specific mechanism is as follows figure 1As shown, polylactic acid is used as the matrix, PLA-g-E1,2-PB is used as the compatibilizer, and 1,2-PB is used as the toughening agent. The polylactic acid, PLA-g-E1,2-PB, and 1,2-PB were placed in a Haake mixer for internal mixing to obtain 1,2-PB toughened and modified polylactic acid.

[0033] Among them, 1,2 polybutadiene (E1,2-PB) with different epoxy degrees can be prepared by the following method: put the dried 1,2-PB in a round bottom flask, add toluene solvent at room te...

Embodiment 1

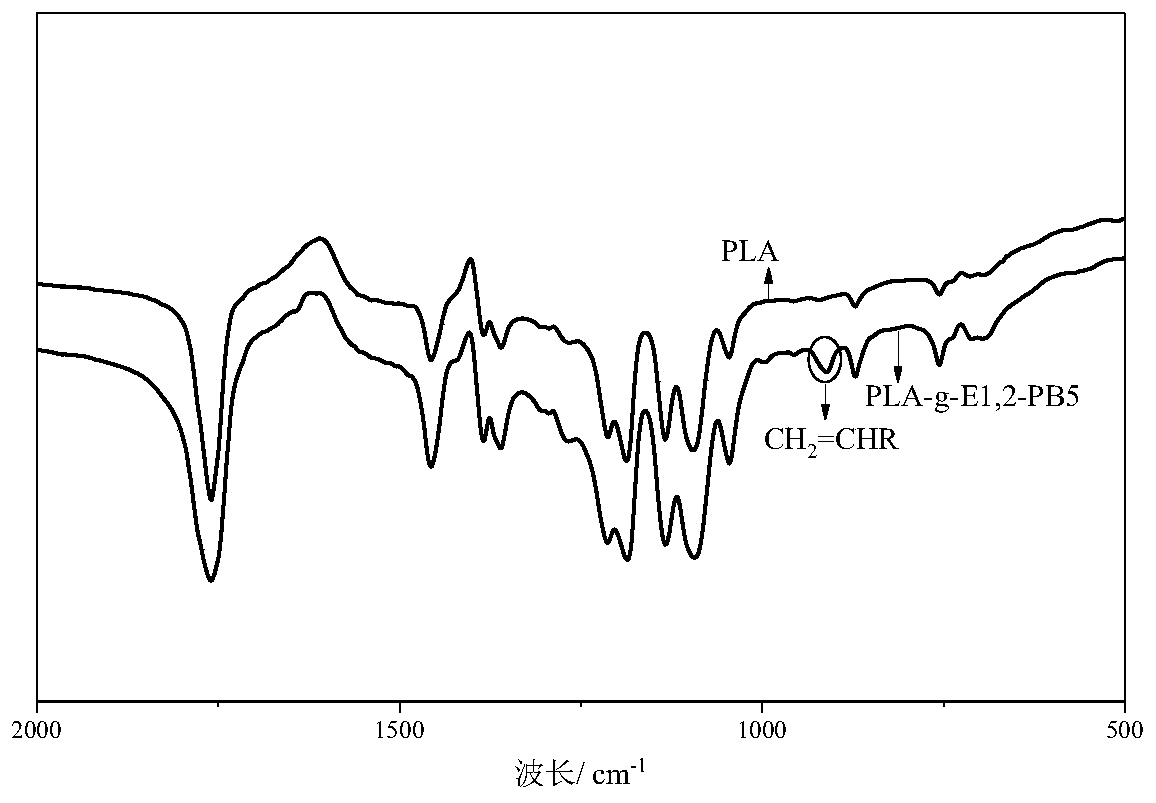

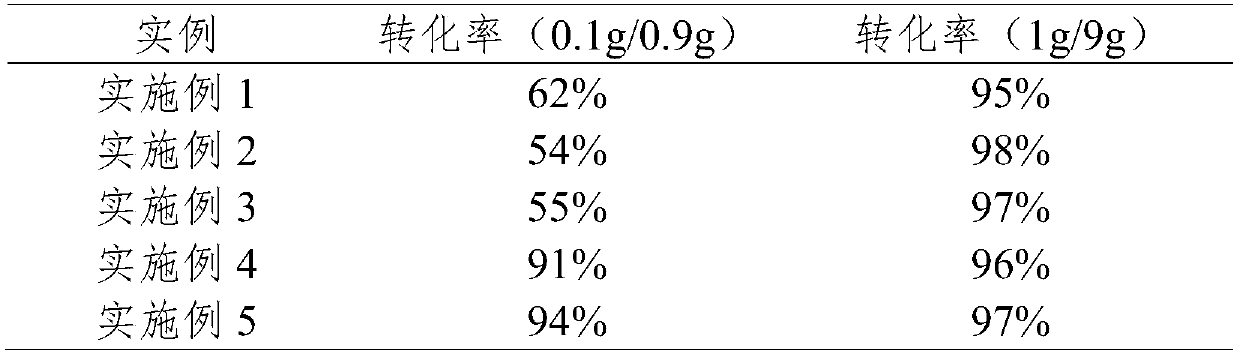

[0043] Put 0.1g of E1,2-PB with 5% epoxy degree and 0.9g of lactide in a test tube, add toluene solvent, after E1,2-PB is completely dissolved, add m-cresol substituted triisobutyl Base aluminum (Fen / Al=1), the molybdenum pentachloride catalyst (mass ratio is 3) that tributyl phosphate replaces, wherein, lactide: aluminum series catalyst: molybdenum series catalyst presses lactide: aluminum element : The molar ratio of the molybdenum element is 1000:30:1, the concentration of lactide is 1mol / L, the reaction is 10h, and the polymerization temperature is 100°C to obtain PLA-g-E1,2-PB5 (number 5 represents ring Oxygen degree is 5%), and its conversion rate is 62%. Such as figure 2 In order to obtain the infrared spectrum of PLA-g-E1,2-PB5, the results proved that PLA-g-E1,2-PB5 was successfully synthesized.

[0044] Put 1g of E1,2-PB with an epoxy degree of 5% and 9g of lactide in a test tube, add toluene solvent, and after E1,2-PB is completely dissolved, add m-cresol-substit...

Embodiment 2

[0046] Put 0.1g of E1,2-PB with 10% epoxy degree and 0.9g of lactide in a test tube, add toluene solvent, after E1,2-PB is completely dissolved, add 2-hydroxy-4-methoxy Triisobutylaluminum (Fen / Al=0.5) substituted by phenylacetophenone, tripropyl phosphate substituted molybdenum pentachloride catalyst (mass ratio is 2.5), wherein, lactide: aluminum series catalyst: molybdenum The molar ratio of the catalyst based on lactide: aluminum element: molybdenum element is 1300:40:1, the concentration of lactide is 0.8mol / L, the reaction is 9h, and the polymerization temperature is 90°C to obtain PLA-g- The conversion rate of E1,2-PB10 was 54%.

[0047] Put 1g of E1,2-PB with an epoxy degree of 10% and 9g of lactide in a test tube, add toluene solvent, after E1,2-PB is completely dissolved, add 2-hydroxy-4-methoxybenzene Triisobutylaluminum (Fen / Al=0.5) substituted by ethyl ketone, molybdenum pentachloride catalyst (mass ratio is 2.5) substituted by tripropyl phosphate, wherein, lacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com