Novel anti-precipitation flame retardant PA6 composite material and preparation method thereof

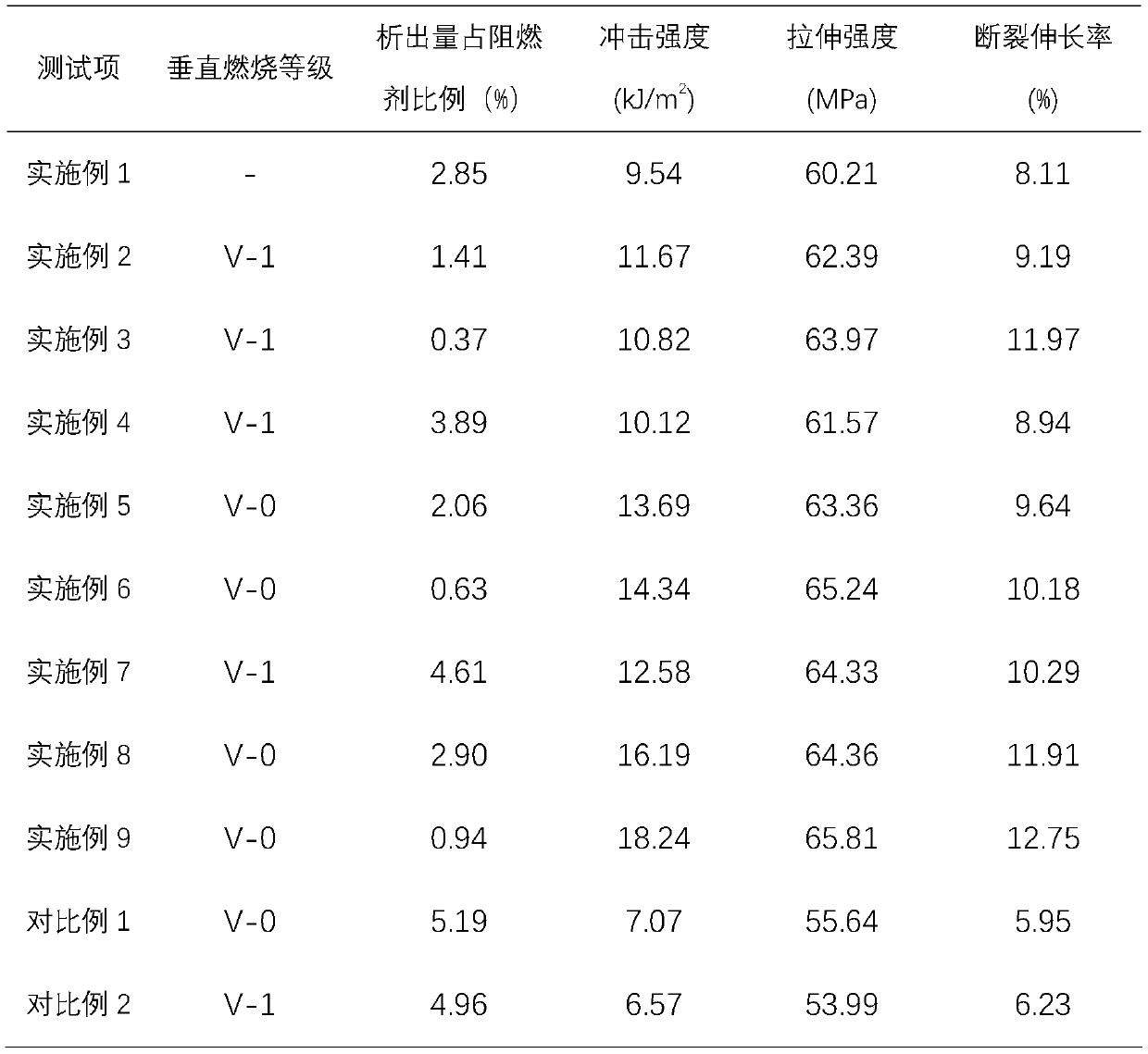

A composite material and anti-precipitation technology, applied in the field of polymer materials, can solve the problems of reducing the mechanical properties of PA6, the migration of flame retardants, and the high cost, and achieve the effects of improving mechanical properties, reducing the amount of precipitation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Stir 98wt% of PA6 particles, 1wt% of melamine and 1wt% of phytic acid in a high-speed mixer for 10 minutes at a stirring speed of 2500r / min;

[0034] (2) Put the mixture of PA6 particles and flame retardant in step (1) in a vacuum drying oven at 80°C for 24 hours;

[0035] (3) The PA6 particles and flame retardant dried in step (2) are extruded in a twin-screw extruder and pelletized. The twin-screw parameters are as follows: the temperature in the first zone is 210±10℃, and the temperature in the second zone is 230± 10℃, three zone temperature is 245±10℃, four zone temperature is 245±10℃, five zone temperature is 230±10℃, head temperature is 220±10℃, twin screw speed is 80r / min, feeder The speed is 6r / min, and the speed of the pelletizer is 300r / min;

[0036] (4) The particles obtained from the granulation in step (3) are injection molded into PA6 splines by a single screw injection molding machine. The temperature of each section of the injection molding machine is 210±...

Embodiment 2

[0038] (1) Stir 96wt% PA6 particles, 1wt% MPP and 3wt% aminotrimethylene phosphoric acid in a high-speed mixer for 10 minutes at a stirring speed of 2500r / min;

[0039] (2) Put the mixture of PA6 particles and flame retardant in step (1) in a vacuum drying oven at 80°C for 24 hours;

[0040] (3) Extrude the PA6 particle and flame retardant mixture dried in step (2) in a twin-screw extruder and pelletize. The twin-screw parameters are the temperature of the first zone is 210±10℃, and the temperature of the second zone is 230 ±10℃, three zone temperature is 245±10℃, four zone temperature is 245±10℃, five zone temperature is 230±10℃, head temperature is 220±10℃, twin screw speed is 80r / min, feeding The speed of the machine is 6r / min, and the speed of the pelletizer is 300r / min;

[0041] (4) The particles obtained from the granulation in step (3) are injection molded into PA6 splines by a single screw injection molding machine. The temperature of each section of the injection molding ma...

Embodiment 3

[0043] (1) Stir 94wt% PA6 particles, 1wt% ammonium acetate and 5wt% ethylenediamine tetramethylene phosphonic acid in a high-speed mixer for 10 minutes at a stirring speed of 2500r / min;

[0044] (2) Put the mixture of PA6 particles and flame retardant in step (1) in a vacuum drying oven at 80°C for 24 hours;

[0045] (3) Extrude the PA6 particle and flame retardant mixture dried in step (2) in a twin-screw extruder and pelletize. The twin-screw parameters are the temperature of the first zone is 210±10℃, and the temperature of the second zone is 230 ±10℃, three zone temperature is 245±10℃, four zone temperature is 245±10℃, five zone temperature is 230±10℃, head temperature is 220±10℃, twin screw speed is 80r / min, feeding The speed of the machine is 6r / min, and the speed of the pelletizer is 300r / min;

[0046] (4) The particles obtained from the granulation in step (3) are injection molded into PA6 splines by a single screw injection molding machine. The temperature of each section o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com