CNF-metal compound independent electrode material and preparation method and application thereof

A metal compound, independent electrode technology, applied in active material electrodes, nanotechnology for materials and surface science, negative electrodes, etc. The effect of increasing the length, reducing the high current discharge and alleviating the volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

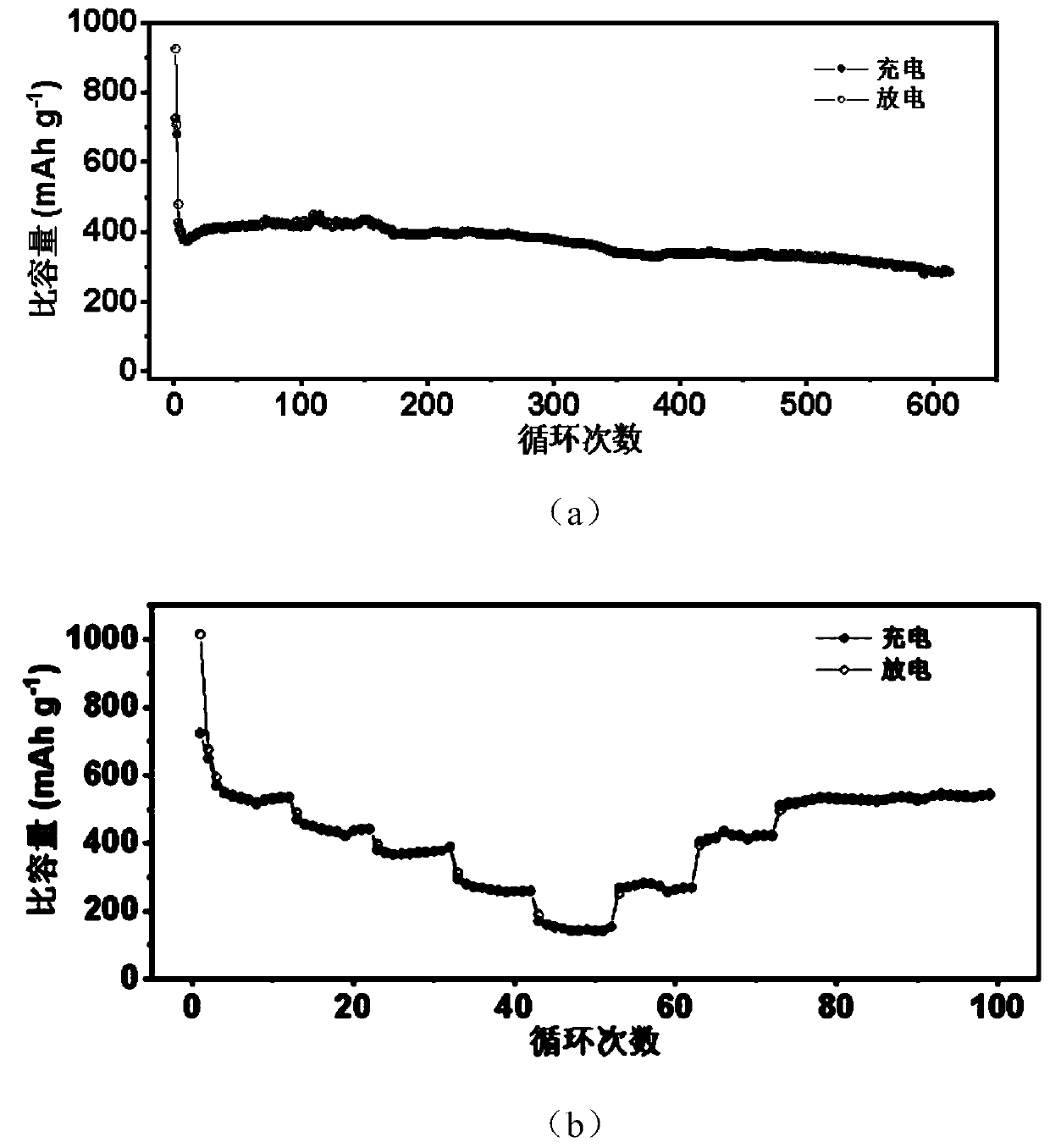

Examples

Embodiment 1

[0034] (1) 1g cobalt acetate (Co(Ac) 2 4H 2 O) and 2g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) Dissolve in 15g dimethylformamide (DMF), add 2.2g polyacrylonitrile (PAN) powder after dissolving completely, stir for 24h, obtain polyacrylonitrile solid content and be the homogeneous mixed spinning solution of 11%.

[0035] (2) Put the mixed spinning solution in a 10ml syringe, use a 20G stainless steel needle, set the spinning parameters: advance speed 1ml / h, voltage 14kV, spinning distance 20cm, use aluminum foil to receive; Dry in an oven at 60°C to obtain a PAN-metal salt nonwoven fabric, which is a blended fiber of metal salt and polymer.

[0036] (3) 4g terephthalic acid is dissolved in 300ml methanol to form a solution with a concentration of 0.15mol / L, and the PAN-metal salt nonwoven fabric obtained in step (2) is soaked in it for 24h, due to cobalt ions, nickel ions and The coordination of terephthalic acid can form a layer of MOF on the surface of the fiber. After takin...

Embodiment 2

[0042] (1) 2.3g cobalt acetate (Co(Ac) 2 4H 2 O) and 1 g zinc acetate (Zn(Ac) 2 2H 2 O) Dissolve in 30g dimethylformamide (DMF), add 3.3g polyacrylonitrile (PAN) powder after completely dissolving, stir in 60 ℃ oil bath for 24h, obtain polyacrylonitrile solid content is 9% homogeneous Mixed spinning solution.

[0043] (2) Put the mixed spinning solution in a 10ml syringe, use a 20G stainless steel needle, set spinning parameters: advance speed 0.6ml / h, voltage 15kV, spinning distance 20cm, use aluminum foil to receive. After spinning, take it off and dry it in an oven at 60°C to obtain a PAN-metal salt nonwoven fabric, which is a metal salt and polymer blended fiber.

[0044] (3) 3g dimethylimidazole is dissolved in 100ml methanol and form concentration is the solution of 0.05mol / L, the PAN-metal salt non-woven fabric that step (2) obtains is immersed in wherein 4h, because cobalt ion, zinc ion and The coordination of dimethylimidazole can form a layer of MOF on the surfa...

Embodiment 3

[0051] (1) 2g cobalt acetate (Co(Ac) 2 4H 2 O) Dissolve in 15g of dimethylformamide (DMF), add 3g of polyacrylonitrile (PAN) powder after dissolving completely, stir in 60 ℃ oil bath for 24h, obtain polyacrylonitrile with solid content of 15% uniform mixing spinning solution.

[0052] (2) Put the mixed spinning solution in a 10ml syringe, use a 20G stainless steel needle, set spinning parameters: advance speed 0.3ml / h, voltage 13kV, spinning distance 22cm, use aluminum foil to receive. After spinning, take it off and dry it in an oven at 60°C to obtain a PAN-metal salt nonwoven fabric, which is a metal salt and polymer blended fiber.

[0053] (3) 10g of dimethylimidazole is dissolved in 200ml of methanol to form a solution with a concentration of 0.1mol / L, and the PAN-metal salt non-woven fabric obtained in step (2) is soaked in it for 24h, due to cobalt ions and dimethyl The coordination of imidazole can form a layer of MOF on the surface of the fiber. After taking it out,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com