A corn stalk/chitin composite hemostatic sponge and its preparation method and application

A corn stalk and hemostatic sponge technology, applied in the application, pharmaceutical formulation, surgical adhesive and other directions, can solve the problems of poor hemostatic performance, insufficient flexibility, etc., and achieve the advantages of low cost, simple preparation method and easy operation, and reduction of secondary bleeding. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

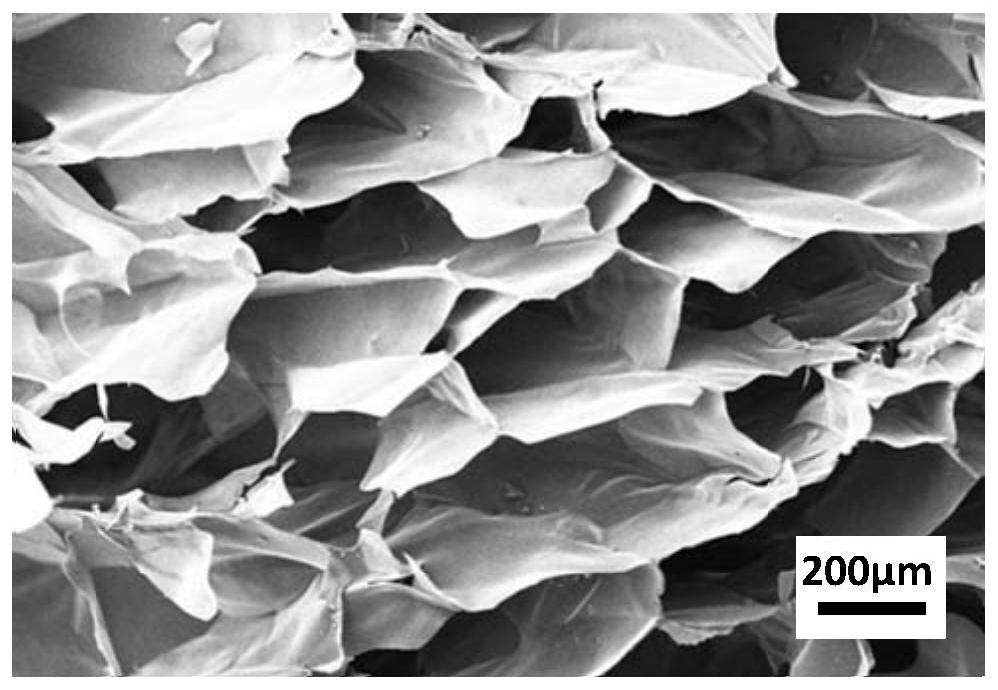

Image

Examples

Embodiment 1

[0046] A preparation method of a corn stalk / chitin composite hemostatic sponge, comprising the steps of:

[0047] (1) After washing and drying the whole component of corn stalks to remove impurities, they are pulverized into powder by a pulverizer to obtain corn stalk powder (particle size is 40-60 mesh), and then the corn stalk powder is processed under the action of mechanical external force of a ball mill. Ball milling (intermittent ball milling, pause for 5 minutes every 10 minutes, and the speed is 200r / min), the time of ball milling is 6 hours, and the corn stalk powder after ball milling is obtained;

[0048] (2) Perform ball milling on chitin under the mechanical external force of the ball mill (intermittent ball milling, stop for 5 minutes every 10 minutes, and the speed is 200r / min), and the time of ball milling is 6 hours to obtain chitin powder;

[0049] (3) Add the ball-milled corn stalk powder in step (1) into the sodium hydroxide / urea solvent, the mass ratio of ...

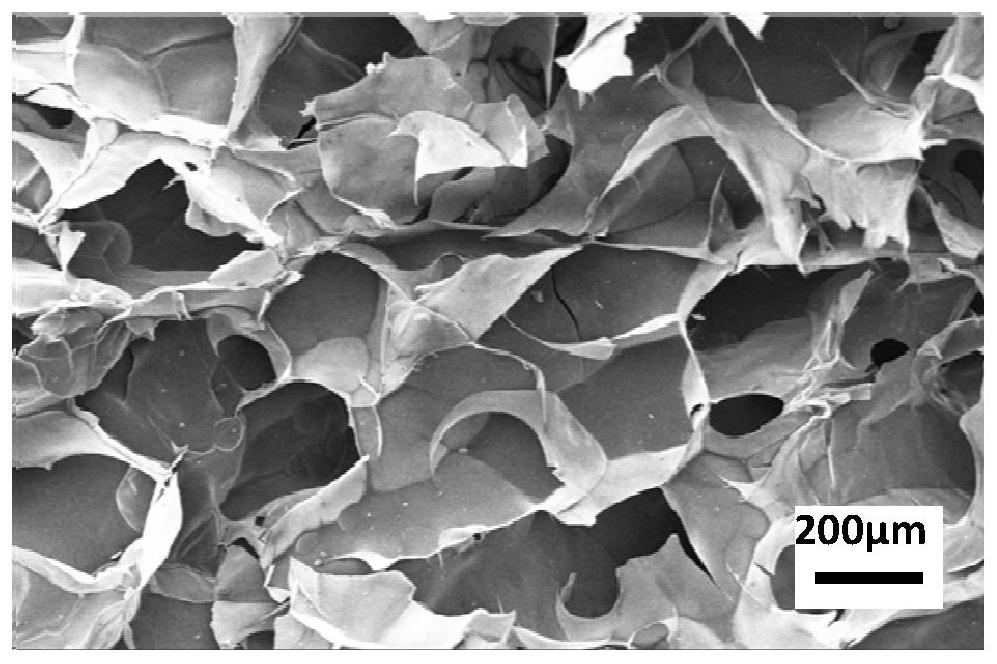

Embodiment 2

[0056] A preparation method of a corn stalk / chitin composite hemostatic sponge, comprising the steps of:

[0057] (1) After washing and drying the whole component of corn stalks to remove impurities, they are pulverized into powder by a pulverizer to obtain corn stalk powder (particle size is 40-60 mesh), and then the corn stalk powder is processed under the action of mechanical external force of a ball mill. Ball milling (intermittent ball milling, stop for 6 minutes every 12 minutes, and the speed is 205r / min), the time of ball milling is 7 hours, and the corn stalk powder after ball milling is obtained;

[0058] (2) Perform ball milling on chitin under the mechanical external force of the ball mill (intermittent ball milling, stop for 6 minutes every 12 minutes, and the speed is 205r / min), and the time of ball milling is 7 hours to obtain chitin powder;

[0059] (3) Add the ball-milled corn stalk powder in step (1) into the sodium hydroxide / urea solvent, the mass ratio of t...

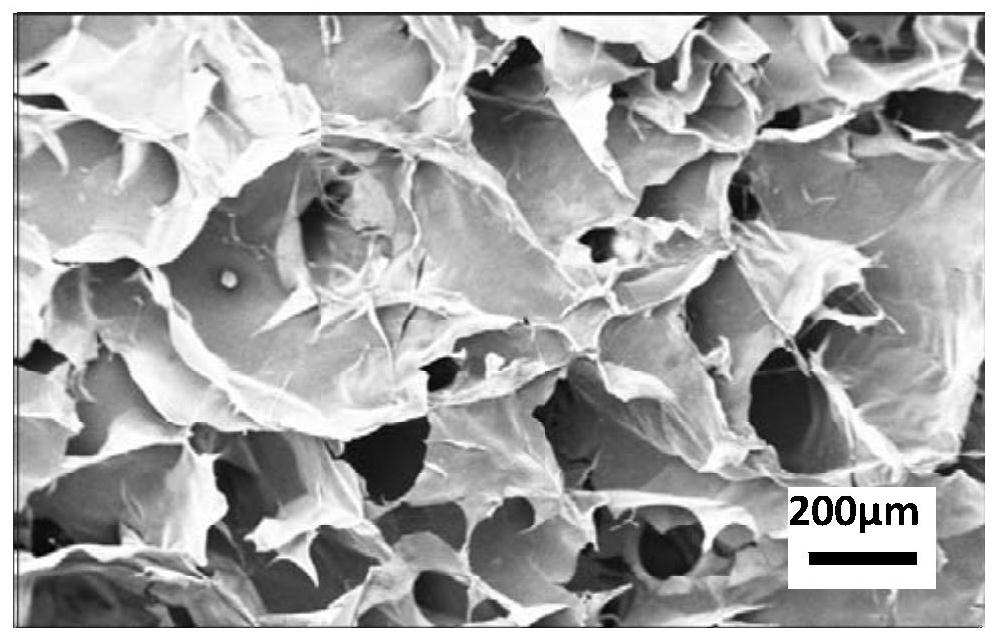

Embodiment 3

[0066] A preparation method of a corn stalk / chitin composite hemostatic sponge, comprising the steps of:

[0067] (1) After washing and drying the whole component of corn stalks to remove impurities, they are pulverized into powder by a pulverizer to obtain corn stalk powder (particle size is 40-60 mesh), and then the corn stalk powder is processed under the action of mechanical external force of a ball mill. Ball milling (intermittent ball milling, stop for 7 minutes every 15 minutes, and the speed is 210 r / min), the time of ball milling is 8 hours, and the corn stalk powder after ball milling is obtained;

[0068] (2) Perform ball milling on chitin under the mechanical external force of the ball mill (intermittent ball milling, stop for 7 minutes every 15 minutes, and the speed is 210 r / min), and the milling time is 8 hours to obtain chitin powder;

[0069] (3) Add the ball-milled corn stalk powder in step (1) into the sodium hydroxide / urea solvent, the mass ratio of the bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com