Preparation method of three-dimensional supported cobalt hydroxide and method of using three-dimensional supported cobalt hydroxide for catalytically treating phenol wastewater by persulfate

A technology of cobalt hydroxide and persulfate, applied in metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult recycling and complex preparation methods, etc. , to achieve the effect of not easy inactivation, simple preparation method and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of foamy nickel-based cobalt hydroxide catalyst and the method for processing phenol waste water are as follows:

[0038] (1) Pretreatment of nickel foam

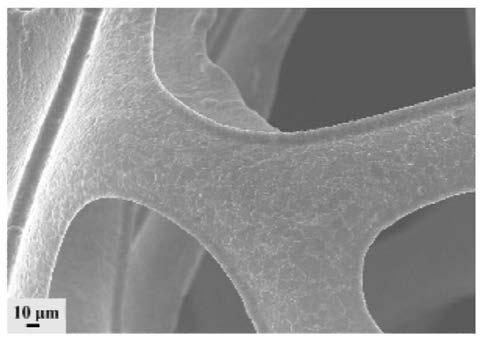

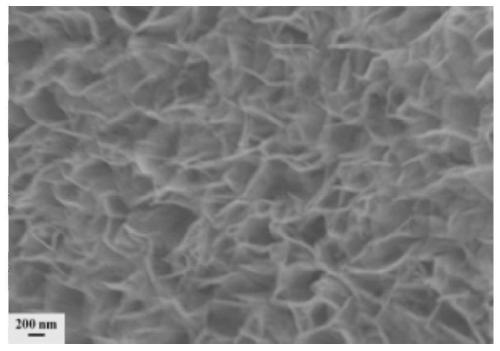

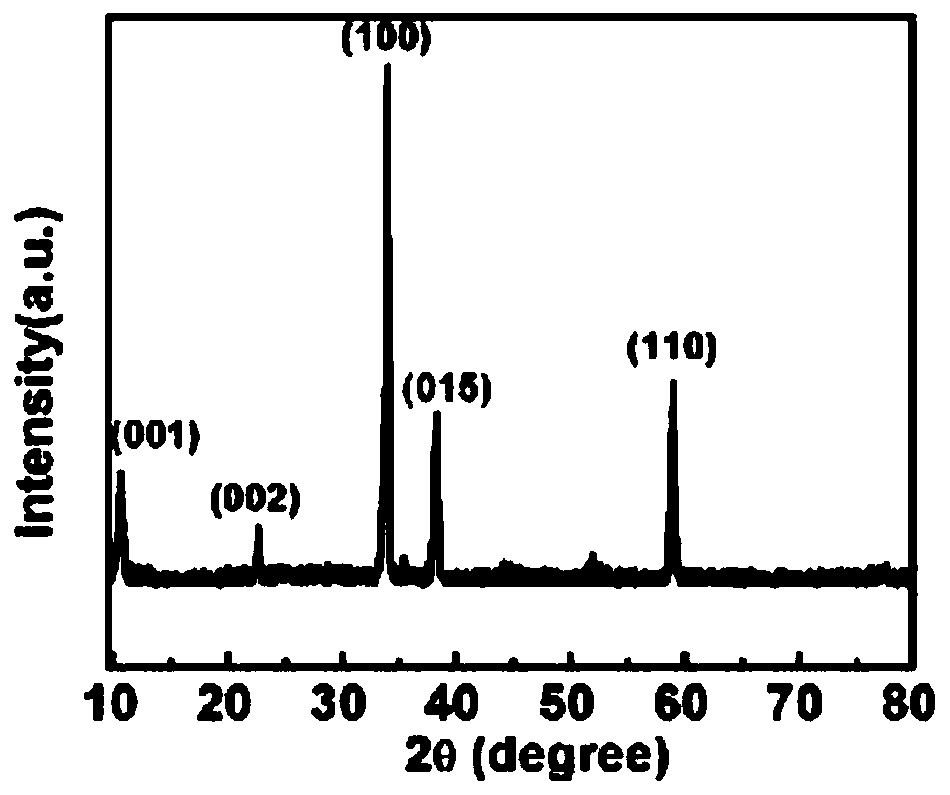

[0039] Soak nickel foam (3cm×4cm×2mm) in acetone and ultrasonicate for 15 minutes to remove a small amount of oil on the nickel foam substrate. Clean the foamed nickel after the above treatment with distilled water for 10 minutes, and then etch it with 5 mol / L hydrochloric acid for 20 minutes to remove the oxide layer on the surface of the substrate and form a microscopic rough surface on the surface of the foamed nickel, thereby enhancing its interaction with cobalt hydroxide. combination. The nickel foam etched by hydrochloric acid was ultrasonically cleaned with distilled water for 15 minutes, then rinsed several times with distilled water, and finally the nickel foam treated above was dried in an oven at 60°C for 2 hours. Observation by scanning electron microscope found that the surface of nick...

Embodiment 2

[0046] The preparation of foamy nickel-based cobalt hydroxide catalyst and the method for processing phenol waste water are as follows:

[0047] (1) Pretreatment of nickel foam

[0048] Soak nickel foam (4cm × 5cm × 2mm) in acetone, ultrasonic 12min, to remove trace oil stains on the nickel foam substrate, thereby increasing the hydrophilicity of the substrate; the nickel foam after the above treatment is ultrasonically cleaned with distilled water for 15min, and then Etch with 8mol / L hydrochloric acid for 15 minutes to remove the oxide layer on the surface of the substrate and form a microscopically rough surface on the surface of the nickel foam, thereby enhancing its bonding force with cobalt hydroxide; the nickel foam etched by hydrochloric acid is ultrasonicated with distilled water Wash for 15 minutes, rinse with distilled water for several times, and finally place the nickel foam treated above in an oven at 80°C for 1.5 hours to dry.

[0049] 2) Preparation of foamed n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com