Hollow spherical carbon nitride photocatalyst, and preparation method and application thereof

A catalyst and spherical technology, applied in the field of photocatalysis, can solve the problems of high hole-electron pair recombination rate, low visible light absorption efficiency, hindering practical application, etc., and achieve the effect of improving catalytic ability, high application prospect, and wide use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

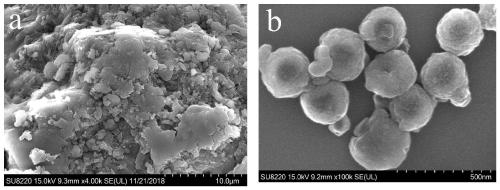

[0035] a g-C 3 N 4 The preparation of hollow sphere (HCNS) photocatalyst comprises the following specific steps:

[0036] 1. Measure 4ml of ammonia water, add 75ml of ethanol and 10ml of ultrapure water into it, and after ultrasonic stirring, add 5ml of tetraethoxysilane (TEOS) into the solution, react for 1 hour, and keep stirring at a constant speed.

[0037] 2. A mixture of 5ml TEOS and 2ml n-octadecyltrimethoxysilane was added dropwise to the mixed solution prepared above, and stood at room temperature for 2h. The solution was centrifuged to obtain a solid, which was then calcined at a high temperature of 500°C. After cooling to room temperature, grind and sieve to obtain a silica sphere template.

[0038] 3. Add 5 g of cyanamide to 1 g of silica template, mix and stir, and calcinate the obtained mixture at 550° C. in a nitrogen atmosphere.

[0039] 4. Add 1M ammonium bifluoride to the obtained powder to remove the template and obtain hollow carbon nitride sphere powde...

Embodiment 2

[0045] a g-C 3 N 4 The preparation of hollow sphere photocatalyst comprises the following specific steps:

[0046] 1. Measure 4ml of ammonia water, add 75ml of ethanol and 10ml of ultrapure water into it, and after ultrasonic mixing, add 6ml of tetraethoxysilane (TEOS) into the solution, react for 1h, and keep stirring at a constant speed.

[0047] 2. A mixture of 6ml TEOS and 3ml n-octadecyltrimethoxysilane was added dropwise to the mixed solution prepared above, and stood at room temperature for 4h. The solution was centrifuged to obtain a solid, which was then calcined at a high temperature of 550°C. After cooling to room temperature, grind and sieve to obtain a silica sphere template.

[0048] 3. 7 g of cyanamide was added to 1 g of silica template, mixed and stirred, and the obtained mixture was calcined at 550° C. in a nitrogen atmosphere.

[0049] 4. Add 1.5M ammonium bifluoride to the obtained powder to remove the template and obtain hollow carbon nitride sphere po...

PUM

| Property | Measurement | Unit |

|---|---|---|

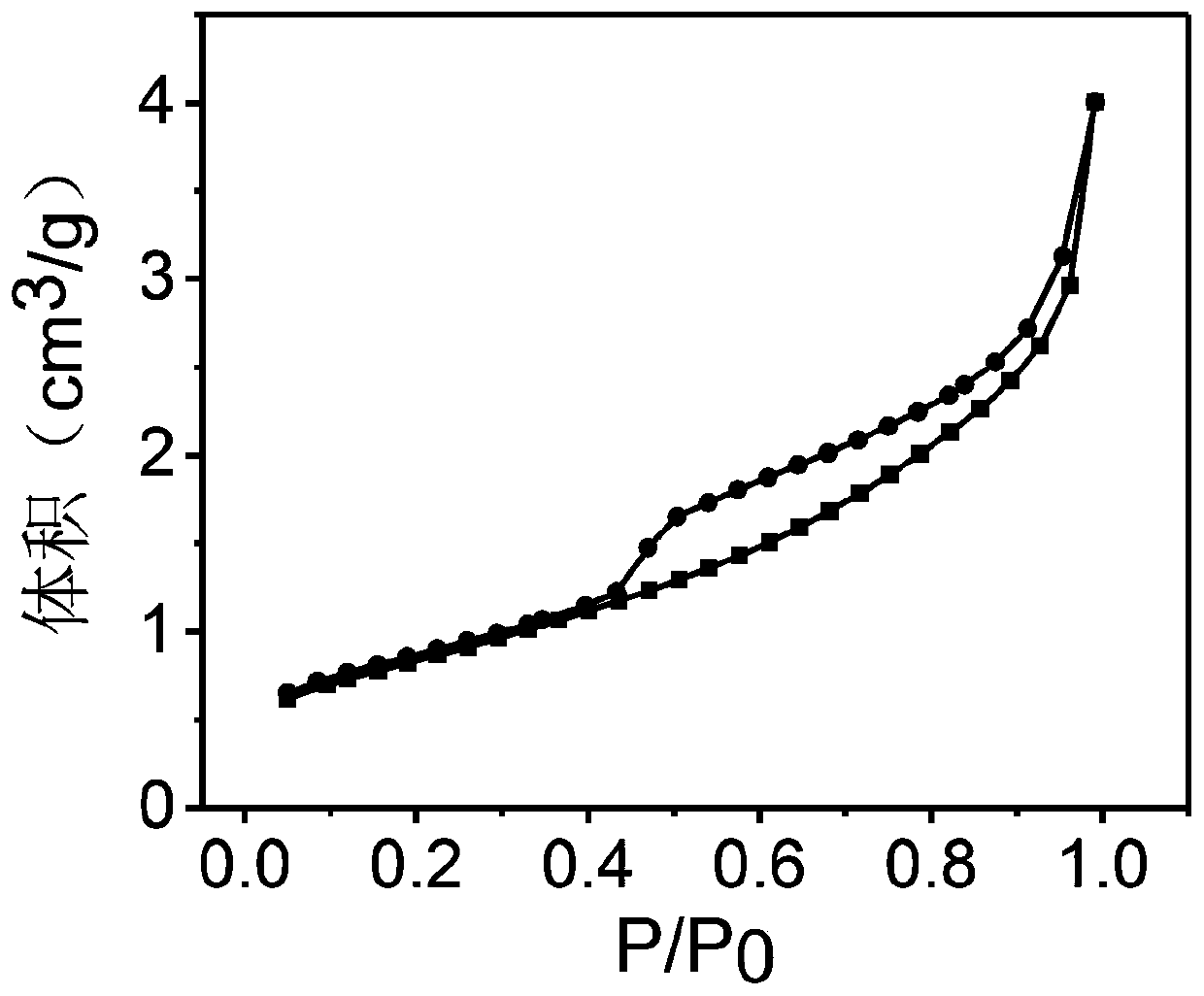

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com