Industrial lignin composite montmorillonite wood modifier as well as preparation method and application thereof

A technology for industrial lignin and montmorillonite, which is applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of harming the environment and human health, low dispersibility of natural montmorillonite, and unsatisfactory effect, and achieves alleviation of pollution. , to achieve high-value utilization, to achieve the effect of resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

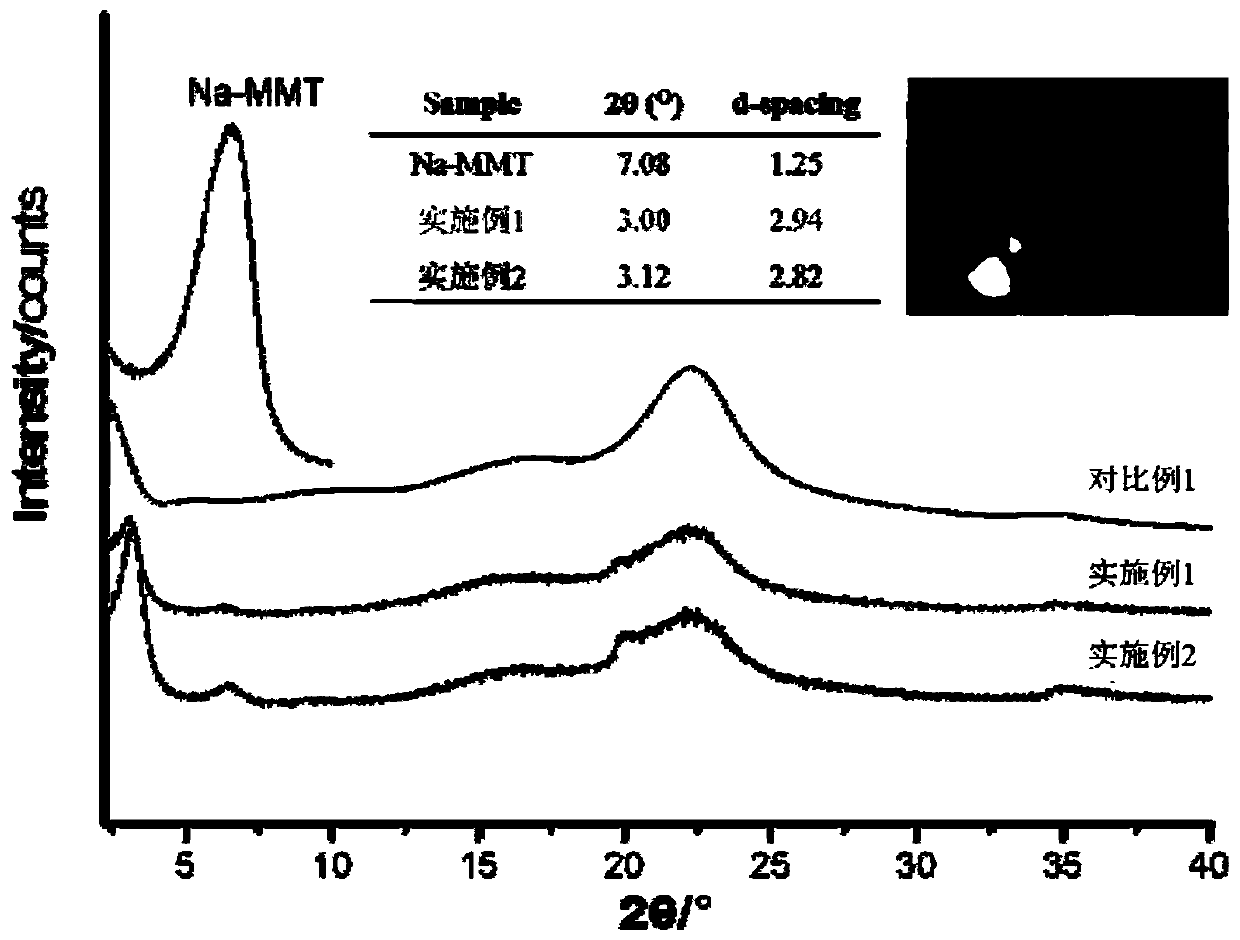

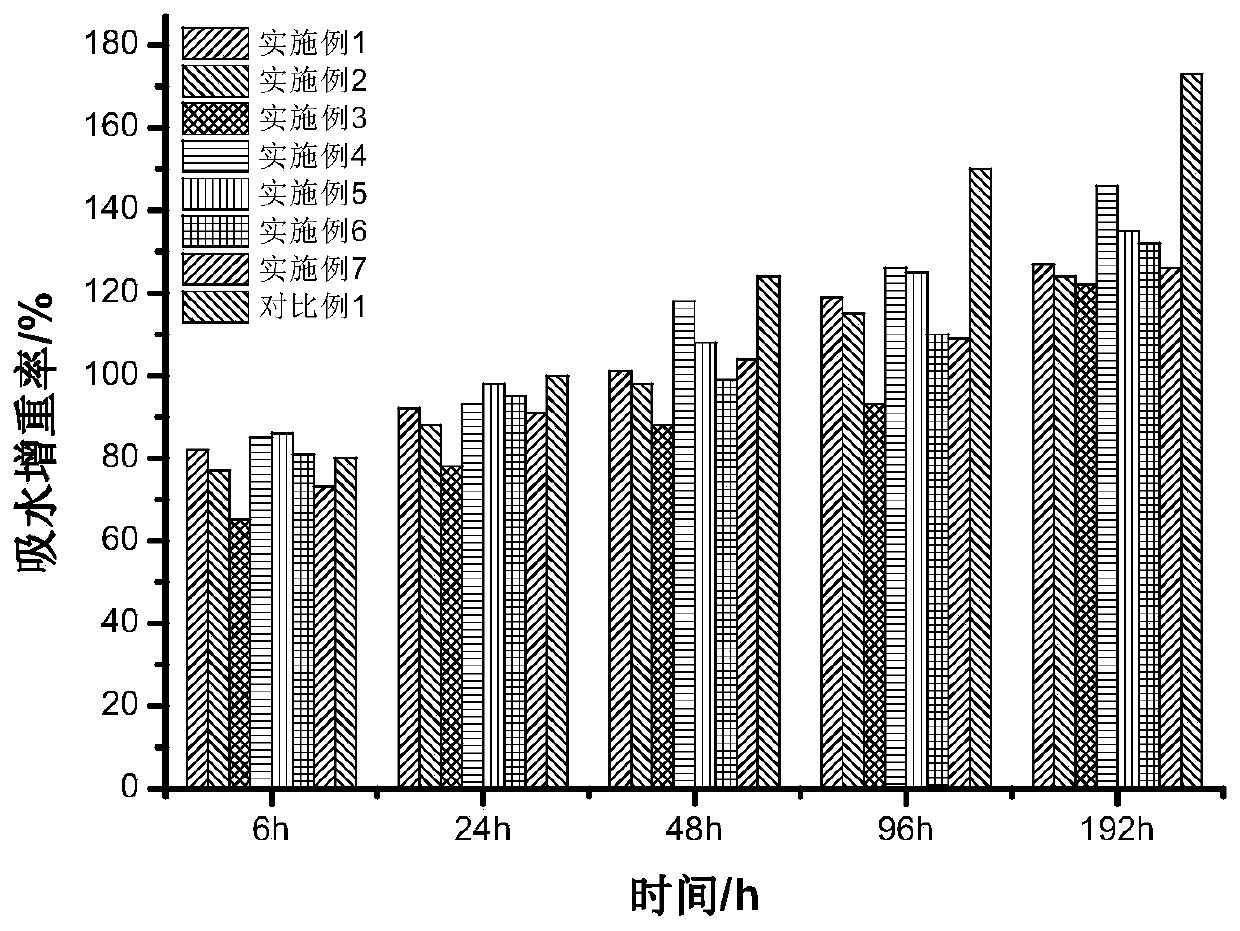

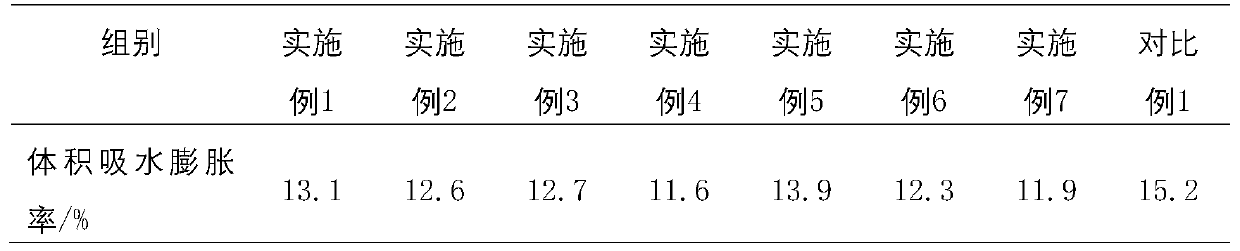

[0030] Sodium montmorillonite (Na-MMT), alkali lignin, cetyltrimethylammonium bromide (CTAB), polyvinyl alcohol (PVA) with a degree of polymerization of 500, ethanol, fast-growing poplar (Populus cathayana Rehd, 20*20*20mm3), are commercially available.

[0031] (1) Preparation of industrial lignin composite montmorillonite modifier

[0032] Select 1 part of Na-MMT, 1 part of CTAB, 1 part of PVA, 20 parts of ethanol, and 50 parts of deionized water. Put the mixture into a beaker and stir it, put it into an ultrasonic oscillator after stirring evenly, and process it with ultrasonic waves for 30 minutes under the condition of 100 Hz to obtain a suspension of montmorillonite.

[0033] Add 1 part of alkali lignin to the montmorillonite suspension, put the mixture into a beaker and stir it, then use a planetary ball mill to disperse the mixture, the experimental conditions are 200r / min, ball milling time 2h, to obtain industrial lignin composite montmorillonite Soil removal modif...

Embodiment 2

[0037] Calcium-based montmorillonite (Ca-MMT), alkali lignin, CTAB, PVA with a degree of polymerization of 4000, ethanol, and fast-growing poplar (Populus cathayana Rehd, 20*20*20mm3), are all commercially available.

[0038] (1) Preparation of industrial lignin composite montmorillonite modifier

[0039] Select 4 parts of Ca-MMT, 3 parts of CTAB, 9 parts of PVA, 50 parts of ethanol, and 133 parts of deionized water. Put the mixture into a beaker and stir it, put it into an ultrasonic oscillator after stirring evenly, and process it with ultrasonic waves for 240 min under the condition of 100 Hz to obtain a montmorillonite suspension.

[0040] Add 20 parts of alkali lignin to the montmorillonite suspension, put the mixture into a beaker and stir it, then use a planetary ball mill to disperse the mixture. The experimental conditions are 180r / min and 4h ball milling time to obtain industrial lignin composite montmorillonite. Soil removal modifier suspension.

[0041] (2) Impre...

Embodiment 3

[0044] Na-MMT, papermaking black liquor, CTAB, PVA with a degree of polymerization of 1000, ethanol, and fast-growing poplar (Populuscathayana Rehd, 20*20*20mm3) are all commercially available.

[0045] (1) Preparation of industrial lignin composite montmorillonite modifier

[0046] Select 6 parts of Na-MMT, 18 parts of CTAB, 7 parts of PVA, 80 parts of ethanol, and 131 parts of deionized water. Put the mixture into a beaker and stir it, put it into an ultrasonic oscillator after stirring evenly, and process it with ultrasonic waves for 120 min under the condition of 100 Hz to obtain a montmorillonite suspension.

[0047] Add 6 parts of paper-making black liquor to the montmorillonite suspension, put the mixture into a beaker and stir it, then use a planetary ball mill to disperse the mixture. The experimental conditions are 240r / min and 3h ball milling time to obtain industrial lignin composite montmorillonite. Soil removal modifier suspension.

[0048] (2) Impregnation tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com