4-hydroxyindole preparation method suitable for industrial production

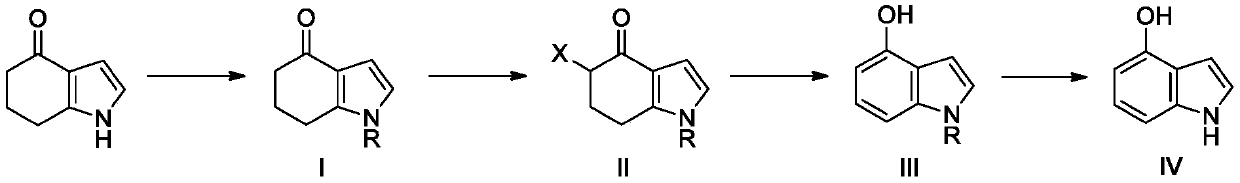

A technology of oxindole and indole, which is applied in the field of preparation of 4-oxindole and industrialized production, can solve the problems of high reaction temperature, harsh conditions, and high equipment requirements, and achieve simplified operation steps, mild reaction conditions, and high reaction yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

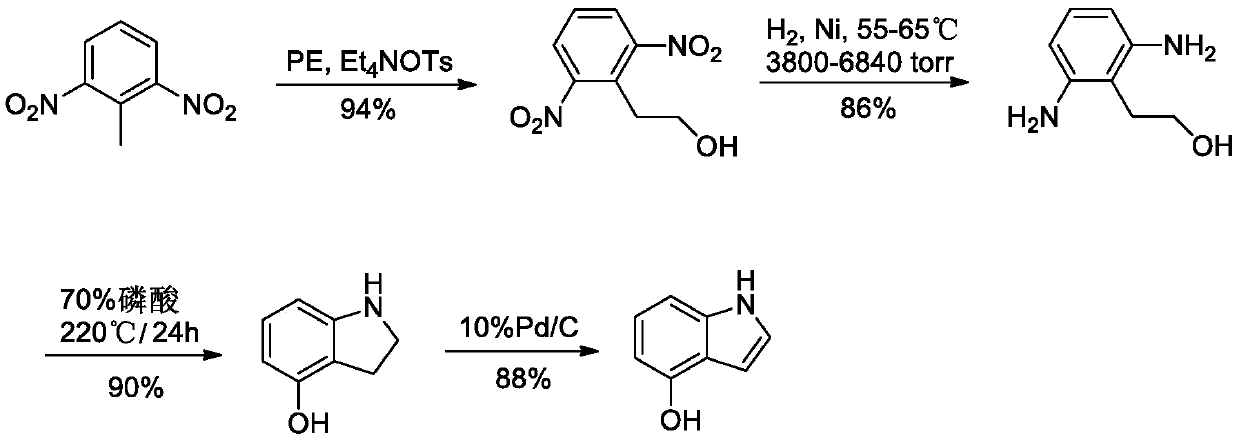

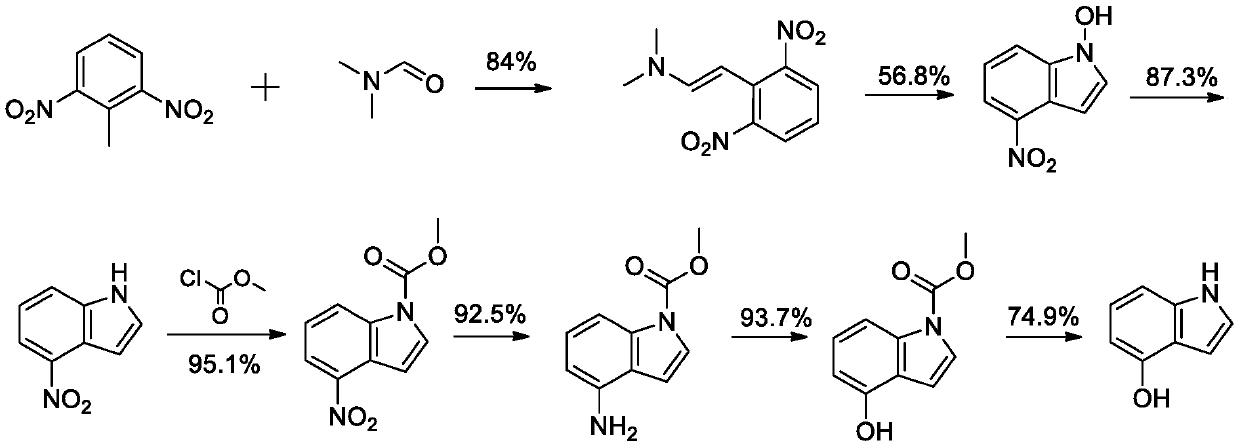

Method used

Image

Examples

Embodiment 1

[0058] NaH (2.64 g) and DMF (120 mL) were added to the reaction flask, and then a DMF solution of 1,5,6,7-tetrahydro-4H-indol-4-one (13.5 g) was added dropwise at 0°C. After stirring for a while, acetyl chloride (8.6 mL) was added dropwise. After the addition, the temperature was raised to room temperature for 3 h, distilled water (200 mL) was added, and extracted with EtOAc (2×100 mL). The organic phase was washed with brine (200mL), Na 2 SO 4 Dry, filter, and concentrate under reduced pressure to obtain 17.2 g of oil I (yield 97%). 1 H-NMR (DMSO) δ7.41 (d, 1H), 6.54 (d, 1H), 3.24 (t, 2H), 3.06 (t, 2H), 2.86 (m, 2H), 2.60 (s, 3H).

Embodiment 2

[0060] Cool the chloroform solution (200mL) of compound I (17.2g) to 0°C, add liquid bromine (1g) dropwise, stir at room temperature after the dropwise addition, pour into ice water after the reaction is complete, separate the liquids, and use 5% saturated carbonic acid for the organic phase Wash with sodium hydrogen, in saturated sodium carbonate solution, extract with ethyl acetate, wash with water, Na 2 SO 4 Dry, concentrate under reduced pressure to obtain a crude product, and refine with ether-isopropanol to obtain 24.3 g of compound II (yield 98%). 1 H-NMR (CDCl 3 )δ7.47(d,1H),6.61(d,1H),2.48(m,2H),4.46(t,1H),2.54(m,2H),2.60(s,3H).

Embodiment 3

[0062] Under nitrogen, compound II (24.3g), DBU (14.5g) and THF (200mL) were added to the reaction flask, stirred at 50°C for 2h, the reaction was completed, cooled to 0°C, added pentane (600mL), filtered, Wash the filter cake with 600 mL THF and pentane (1:1), and concentrate by distillation to obtain 16 g of compound III (96% yield). 1 H-NMR (CDCl 3 ) 2.31 (s, 3H), 5.25 (s, 1H), 6.48-7.84 (m, 5H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com