Preparation method for one-dimensional tubular MOF material, and preparation and application of one-dimensional nitrogen-doped porous carbon nanotube material

A technology of MOF and nanotubes, which is applied in the direction of carbon nanotubes, nanocarbons, electrical components, etc., can solve the problems of low specific capacity and restrict the development of lithium-ion batteries, and achieve high porosity, high yield, and less variety requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. Preparation of ZnCo-BTC nanowire powder.

[0033] (1) 0.42g of 1,3,5-trimesic acid was dissolved in 90ml of deionized water to form solution I, 0.25g of cobalt acetate tetrahydrate and 0.22g of zinc acetate dihydrate were dissolved in 10ml of deionized water to form solution II, When solution I is preheated to 100°C in an oil bath, add solution B, stir and react at a constant temperature for 1 min, centrifuge the product, wash it with ethanol, and dry it in an oven at 80°C to obtain ZnCo-BTC nanowire powder .

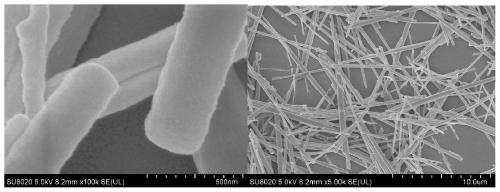

[0034] figure 1 For the ZnCo-BTC nanowire material prepared in this example, it can be seen that the unconverted MOFs materials are all one-dimensional nanomaterials, and the surface is relatively smooth.

Embodiment 2

[0035] Example 2. Preparation of one-dimensional tubular MOF materials by ZnCo-BTC nanowires

[0036] (1) 20mg ZnCo-BTC nanowire powder is dispersed in 30ml ethanol aqueous solution (V 醇 :V 水 =9:1), forming a uniform suspension A, 4g of 2-methylimidazole was dissolved in 10ml of aqueous ethanol (V 醇 :V 水 =9:1), forming solution B, preheating B in a water bath to 45°C, adding A, stirring at constant temperature for 15 minutes.

[0037] (2) Centrifuge the product, wash it with ethanol three times, and then wash it twice with deionized water, and dry it in an oven at 80°C to obtain a one-dimensional tubular MOF material powder.

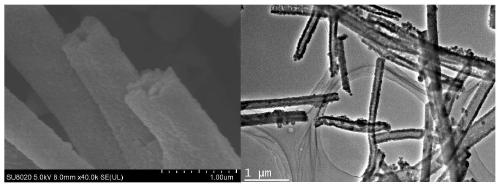

[0038] figure 2 FESEM image and TEM image of the one-dimensional tubular MOF material powder prepared for this example. The FESEM image shows that the originally smooth nanowire surface becomes rough, and the TEM image shows a tubular structure. Figure 4 In the XRD pattern of the one-dimensional tubular MOF material prepared for this example, it ...

Embodiment 3

[0039] Example 3. Preparation of nitrogen-doped porous carbon material from one-dimensional tubular MOF material

[0040] (1) The one-dimensional tubular MOF material prepared by ZnCo-BTC was annealed at 900 ° C under argon protection, and kept for 2 hours; the one-dimensional tubular nitrogen-doped porous carbon material was obtained.

[0041] (2) The one-dimensional tubular nitrogen-doped porous carbon material was placed in a nitric acid solution (concentrated nitric acid: water = 1:2), and stirred and reacted in a water bath at 80° C. for 24 hours.

[0042] (3) Centrifuge the product, wash it with ethanol, and dry it in an oven at 80° C. to obtain a one-dimensional nitrogen-doped porous carbon nanotube material.

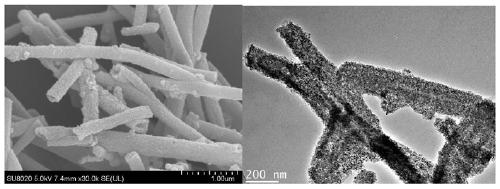

[0043] image 3 It is the FESEM image and TEM image of the one-dimensional tubular nitrogen-doped porous carbon material prepared in this example, indicating that after annealing and pickling steps, the morphology of the one-dimensional tubular MOF material can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com