Nanorod alpha-ferric oxide composite MIL-101 heterojunction photo-anode and preparation method thereof

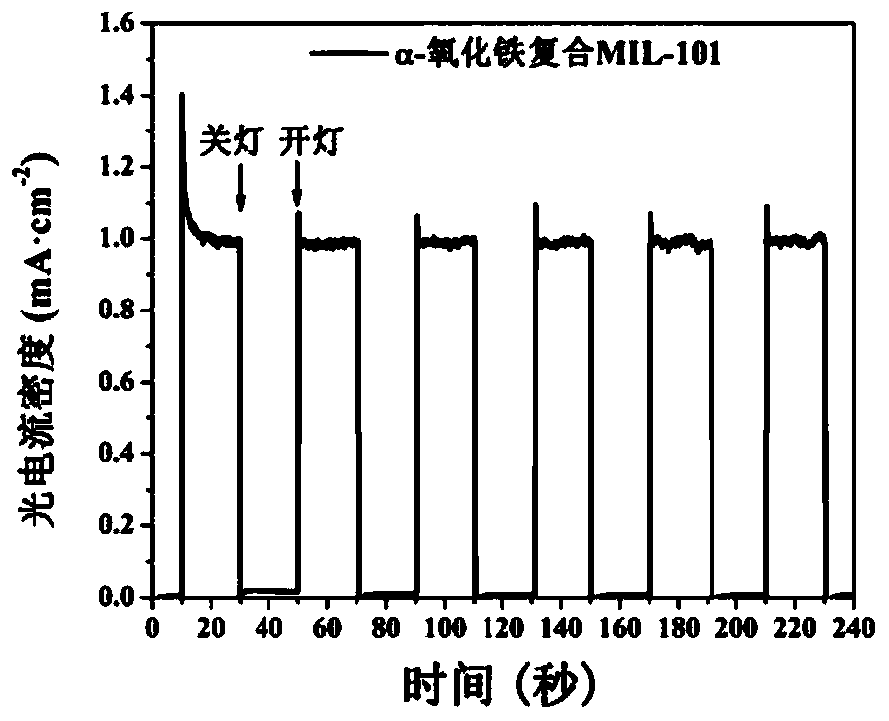

A technology of iron oxide and nanorods, which is applied in the field of nanorod α-iron oxide composite MIL-101 heterojunction photoanode and its preparation, can solve problems such as difficult operation, complicated process, and limited photoanode water splitting performance, and achieve Improve the effect of separation, simple and good process, and high-efficiency photocatalytic water splitting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

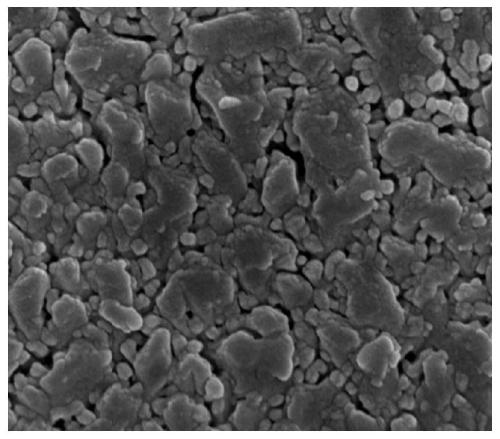

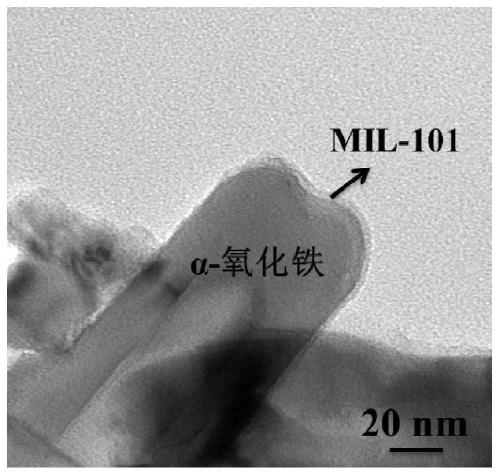

[0027] A nanorod α-iron oxide composite MIL-101 heterojunction photoanode and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0028] Step 1. Dissolving 0.6-0.7 parts by mass of ferric chloride hexahydrate and 0.1-0.2 parts by mass of urea in 50 parts by mass of deionized water, and stirring for 5-15 minutes to obtain a precursor solution of α-iron oxide.

[0029] Step 2, placing the conductive glass in the reactor, with the conductive surface of the conductive glass facing the inner wall of the reactor; then transferring the precursor solution of α-iron oxide to the reactor and sealing it; then The hydrothermal reaction is carried out under the condition of 80-100 DEG C, and the time of the hydrothermal reaction is 4-6 hours, washed and dried to obtain the iron oxyhydroxide nanorod array.

[0030] Step 3, placing the iron oxyhydroxide nanorod array in a crucible, raising the temperature to 400-500°C in an air atmosphere, k...

Embodiment 2

[0033] A nanorod α-iron oxide composite MIL-101 heterojunction photoanode and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0034] Step 1. Dissolve 0.7-0.8 parts by mass of ferric chloride hexahydrate and 0.2-0.3 parts by mass of urea in 50 parts by mass of deionized water, and stir for 15-25 minutes to obtain a precursor solution of α-iron oxide.

[0035]Step 2, placing the conductive glass in the reactor, with the conductive surface of the conductive glass facing the inner wall of the reactor; then transferring the precursor solution of α-iron oxide to the reactor and sealing it; then The hydrothermal reaction is carried out under the condition of 100-120 DEG C, the time of the hydrothermal reaction is 6-8 hours, washing and drying are carried out to obtain the iron oxyhydroxide nanorod array.

[0036] Step 3: Place the iron oxyhydroxide nanorod array in a crucible, raise the temperature to 500-600°C in an air atmosphe...

Embodiment 3

[0039] A nanorod α-iron oxide composite MIL-101 heterojunction photoanode and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0040] Step 1. Dissolving 0.8-0.9 parts by mass of ferric chloride hexahydrate and 0.3-0.4 parts by mass of urea in 50 parts by mass of deionized water, and stirring for 25-35 minutes to obtain a precursor solution of α-iron oxide.

[0041] Step 2, placing the conductive glass in the reactor, with the conductive surface of the conductive glass facing the inner wall of the reactor; then transferring the precursor solution of α-iron oxide to the reactor and sealing it; then The hydrothermal reaction is carried out under the condition of 120-140 DEG C, and the hydrothermal reaction time is 8-10 hours, washed and dried to obtain the iron oxyhydroxide nanorod array.

[0042] Step 3: Place the iron oxyhydroxide nanorod array in a crucible, raise the temperature to 600-700°C in an air atmosphere, keep it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com