Production method of non-fried instant squid crisps

A production method and non-fried technology, applied in the field of food processing, can solve the problems of squid shape damage, adverse effect on flavor, unfavorable quality maintenance, etc., and achieve the effects of reducing fat oxidation and protein oxidation, convenient cooling, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

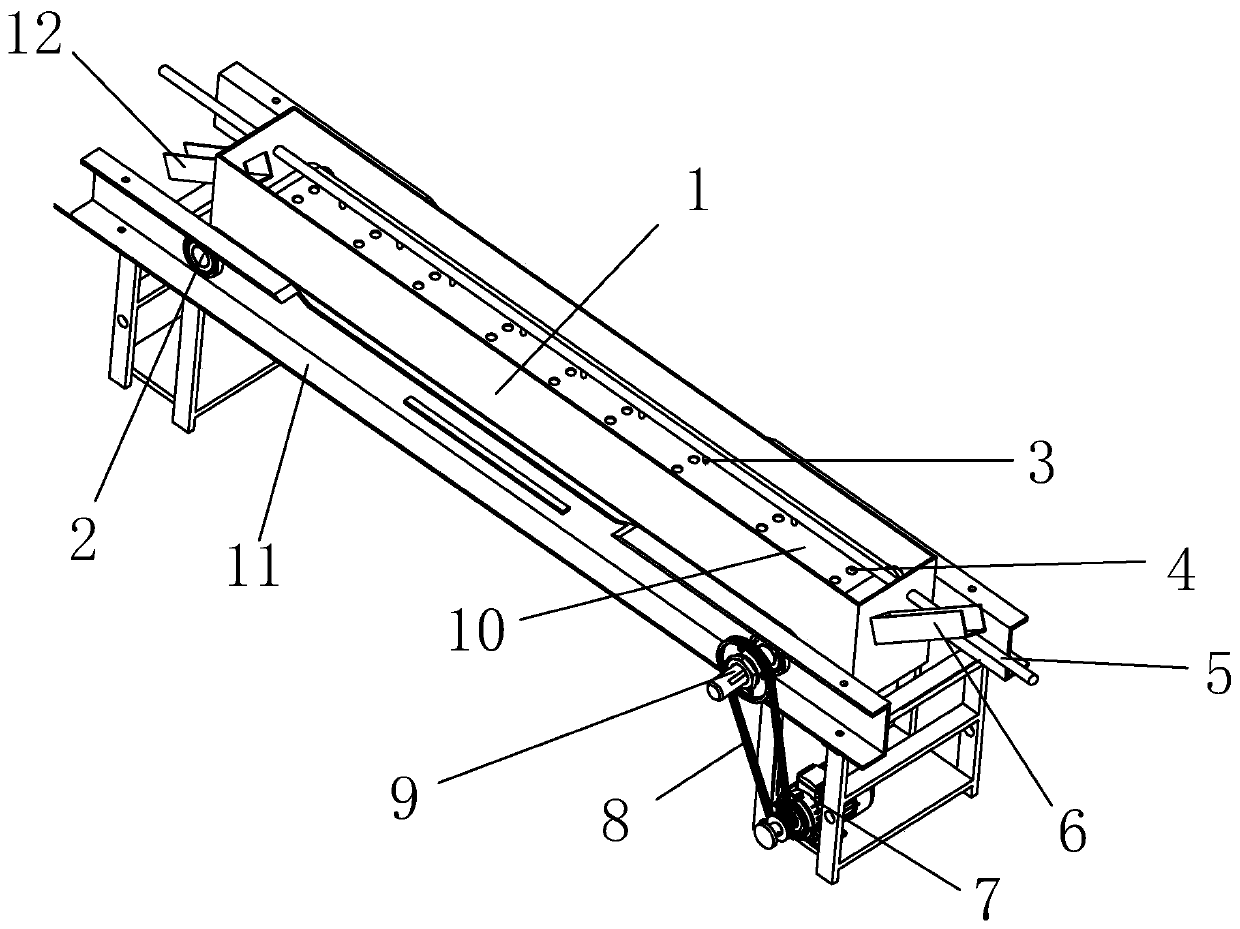

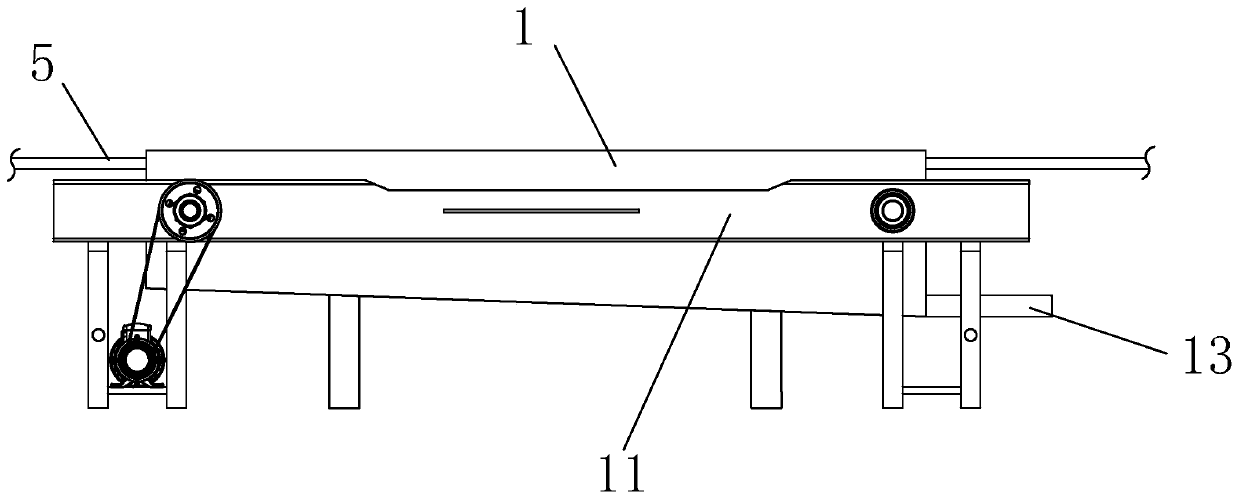

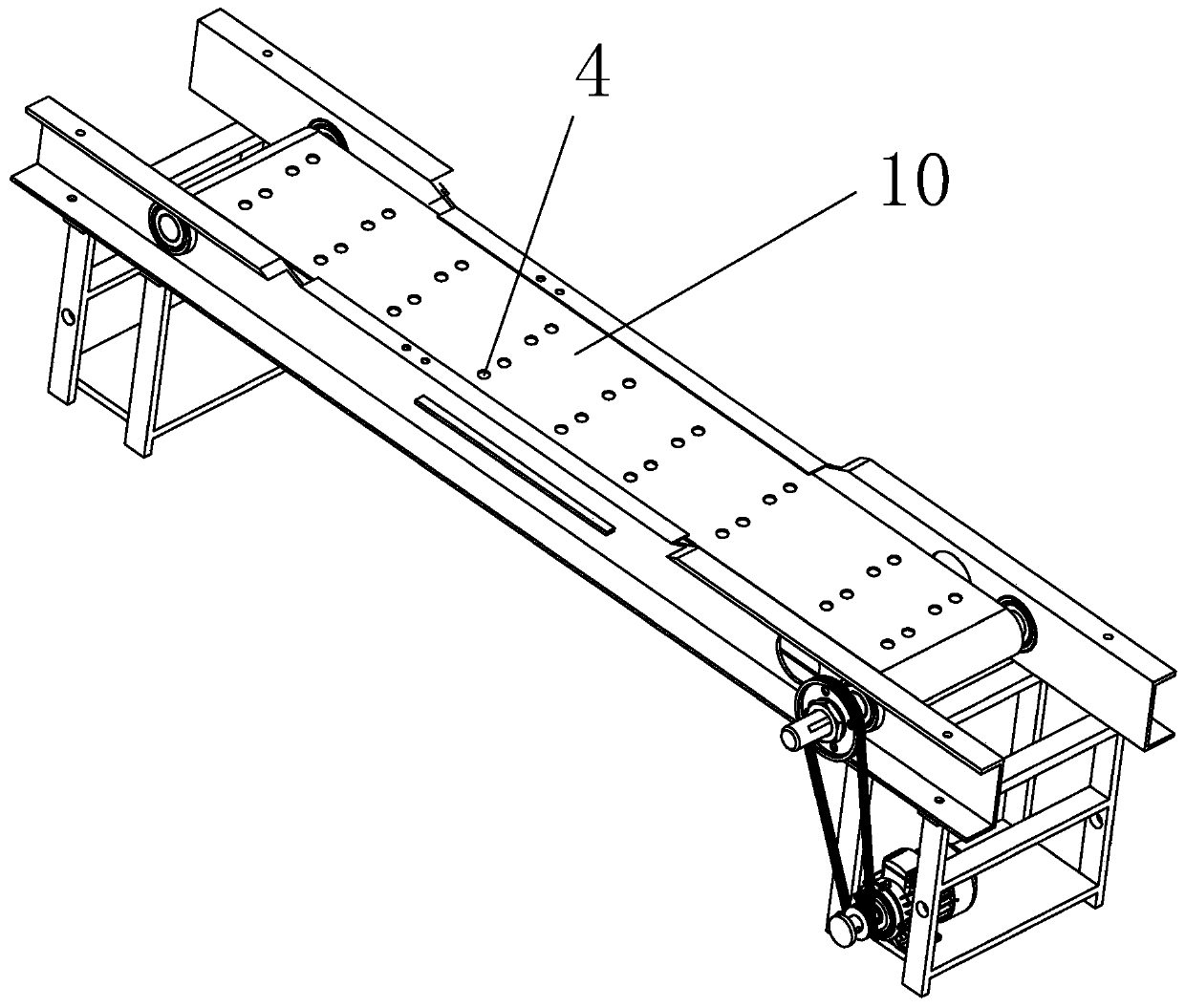

Image

Examples

Embodiment 1

[0025] A kind of production method of non-fried instant squid crispy, carries out according to the following steps:

[0026] Step 1, packing the pretreated squid into a polyethylene bag, the pretreatment step includes getting fresh squid, removing the head, viscera and skin, and cleaning;

[0027] Step 2: Based on the weight of the squid, add the seasoning liquid into the polyethylene bag at a ratio of 1:1, and then seal it with a vacuum packaging machine; the formula for each kilogram of the seasoning liquid is as follows: 3~5g fennel, 2~3g cinnamon , 2~3g ginger, 2~3g star anise, 10~30g monosodium glutamate, 30~50g refined salt, 50-60g white sugar, 3~5g white vinegar, 3~5g sorbitol, 0.2-0.3g aspartame, the balance water; preparation of seasoning liquid: add spice packs containing fennel, cinnamon, ginger, and star anise to the water, simmer for 45 minutes, then add refined salt, sugar, sorbitol, and aspartame, stir to dissolve completely, then add white vinegar, Stir and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com