A nitric oxide releasing ointment and its preparation method and application

A technology of nitric oxide and ointment, applied in the field of pharmaceutical materials and biomedical materials, can solve problems such as large side effects and drug resistance of the body, and achieve the effects of lightening the burden, no skin irritation, and prolonging the release time of NO.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

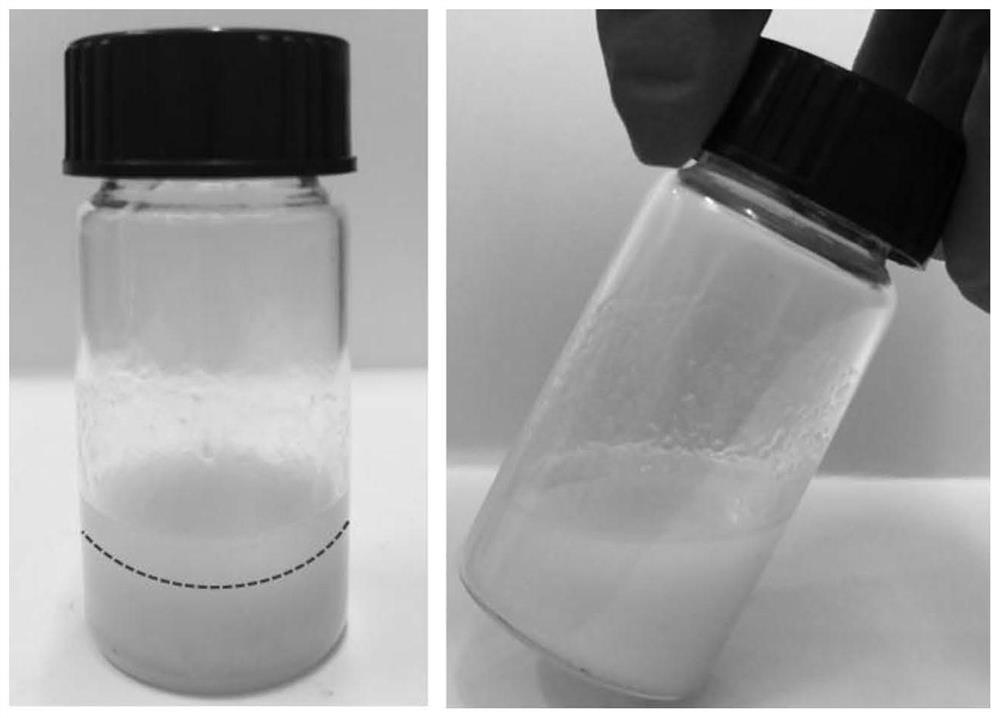

Image

Examples

preparation example Construction

[0046] The anhydrous methanol described in the examples of the present application is prepared by the following method: calcium hydride is added to methanol, stirred for 12 hours, and then distilled at atmospheric pressure to obtain anhydrous methanol. 1 gram meter.

[0047] The anhydrous ether was prepared by the following method: calcium hydride was added to ether, stirred for 12 hours, and then distilled under atmospheric pressure to obtain anhydrous ether, and the amount of calcium hydride added was 1 gram per 500 mL of ether.

[0048] The anhydrous tetrahydrofuran was prepared by the following method: calcium hydride was added to tetrahydrofuran, stirred for 12 hours, and then distilled at atmospheric pressure to obtain anhydrous tetrahydrofuran, and the amount of calcium hydride added was 1 gram per 500 mL of tetrahydrofuran.

[0049] The dry polyethyleneimine is prepared by the following method: weigh a certain amount of polyethyleneimine PEI in a vacuum drying oven, pl...

Embodiment 1

[0052] (1) Preparation of polyethyleneimine (PEI) NO donor material PEI / NONOate

[0053] Under the condition of room temperature and 35°C, a certain quality of dry polyethyleneimine (number average molecular weight is 600) is dissolved in a mixed solution of anhydrous methanol and tetrahydrofuran (the volume ratio of anhydrous methanol and tetrahydrofuran is 1:1), and the The amount of water and methanol is based on dissolving 0.1g PEI per 10mL. After dissolving for 5 minutes, add dry sodium methoxide, wherein the mass ratio of polyethyleneimine PEI and sodium methoxide is 1:10. After continuing to dissolve and stabilize for 30 minutes, a mixed solution is obtained. The mixed solvent is added into the autoclave, sealed and tested for air tightness. High-purity nitrogen was maintained in the reactor (20 psi) for 20 minutes to remove the air in the reactor, and then NO gas (80 psi) was introduced, and the reaction was carried out at room temperature at 35° C. for 7 days. After ...

Embodiment 2

[0081] Preparation of polyethyleneimine (PEI) NO donor material PEI / NONOate

[0082] Under the condition of room temperature and 25°C, take a certain quality of dry polyethyleneimine (number average molecular weight is 70000) and dissolve it in the mixed solution of anhydrous methanol and tetrahydrofuran (the volume ratio of anhydrous methanol and tetrahydrofuran is 1:2). The amount of water and methanol is based on 0.5g PEI per 10mL dissolved. After dissolving for 30 minutes, add dry sodium methoxide, wherein the mass ratio of polyethyleneimine PEI and sodium methoxide is 1:100. After continuing to dissolve and stabilize for 60 minutes, a mixed solution is obtained. The mixed solvent is added into the autoclave, sealed and tested for air tightness. High-purity nitrogen was maintained in the reactor (50 psi) for 10 minutes to remove the air in the reactor, and then NO gas (120 psi) was introduced to react at room temperature at 25° C. for 3 days. After the reaction was finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com