Non-noble metal hydrogen evolution electrocatalyst based on synergistic modification and preparation method thereof

A non-precious metal, synergistic modification technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of poor long-term working stability and high potential, and achieve optimized intrinsic activity, simple process, The effect of improving mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

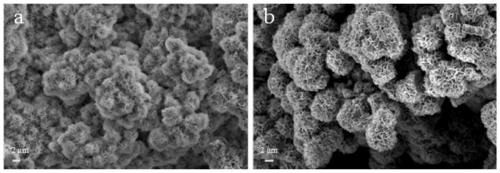

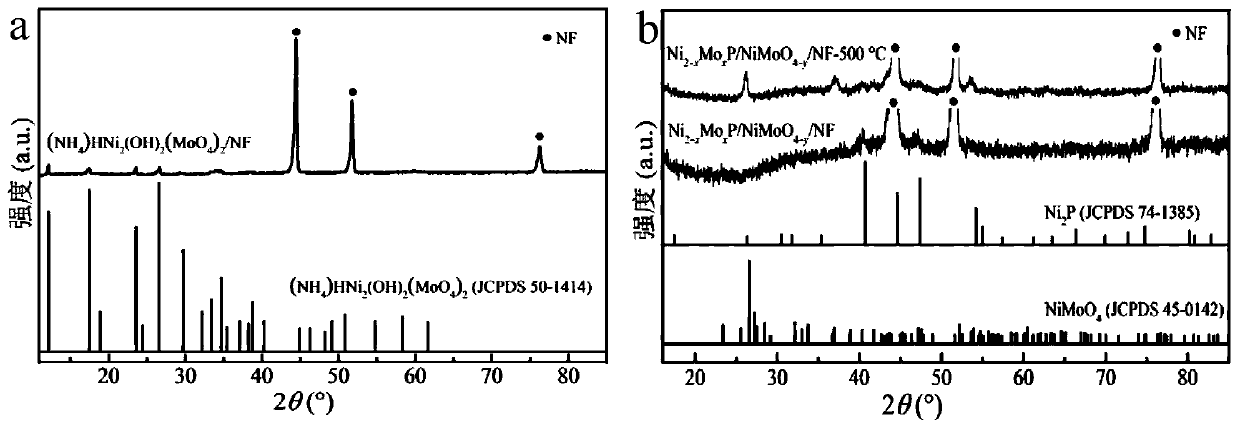

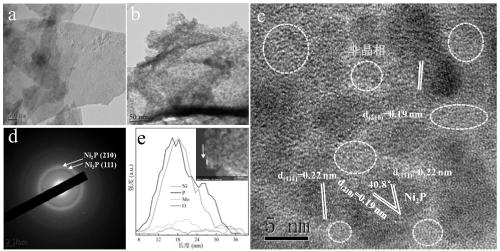

[0040] (1) With nickel foam (NF) as the carrier, its thickness is 1.85mm, and its surface density is 620±30g / m 2 , the aperture is 0.20 ~ 0.80mm. Nickel Foam (1×4cm 2 ) was ultrasonically cleaned with ethanol for 10 minutes and activated with 3M hydrochloric acid solution for 10 minutes, together with 30 mL of Ni(NO 3 ) 2 ·6H 2 O(0.1M), (NH 4 ) 6 Mo 7 o 24 4H 2 O(0.025M), (NH 2 ) 2 The deionized aqueous solution of CO (0.25M) was placed in a hydrothermal ax with a volume of 50mL, and after being treated at a constant temperature of 150°C for 18 hours, it was naturally cooled to room temperature. The prepared sample was fully cleaned and then vacuum dried at room temperature for 1 hour to obtain water Hot sample (NH 4 )HNi 2 (OH) 2 (MoO 4 ) 2 / NF.

[0041] (2) Place about 1 g of sodium hypophosphite and hydrothermal samples in a quartz boat at an interval of 1 cm, heat to 300 ° C under an argon atmosphere, and the heating rate is 2 ° C / min, and cool to room te...

Embodiment 2

[0056] (1) With nickel foam (NF) as the carrier, its thickness is 1.85mm, and its surface density is 620±30g / m 2 , the aperture is 0.20 ~ 0.80mm. Nickel Foam (1×4cm 2 ) was ultrasonically cleaned with ethanol for 10 minutes and activated with 3M hydrochloric acid solution for 10 minutes, together with 30 mL of Co(NO 3 ) 2 ·6H 2 O(0.02M), Na 2 MoO 4 2H 2 O (0.01M) deionized aqueous solution was placed in a hydrothermal ax with a volume of 50 mL, and after being treated at a constant temperature of 150 ° C for 6 hours, it was naturally cooled to room temperature. Hot sample CoMoO 4 ·nH 2 O.

[0057] (2) Place about 1 g of sodium hypophosphite and hydrothermal samples in a quartz boat at an interval of 1 cm, heat to 300 ° C under an argon atmosphere, and the heating rate is 2 ° C / min, and cool to room temperature after 3 hours of constant temperature treatment to prepare The target catalyst Co 3 P / CoMoO 4 / NF.

[0058] The hydrothermal state sample CoMoO obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com