A kind of preparation method of high α-phase silicon nitride powder body and ultra-long silicon nitride nanowire

A technology of phase silicon nitride powder and silicon nitride nanometer is applied in the field of preparation of non-oxide ceramic materials to achieve the effect of shortening the nitriding cycle and speeding up the nitriding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

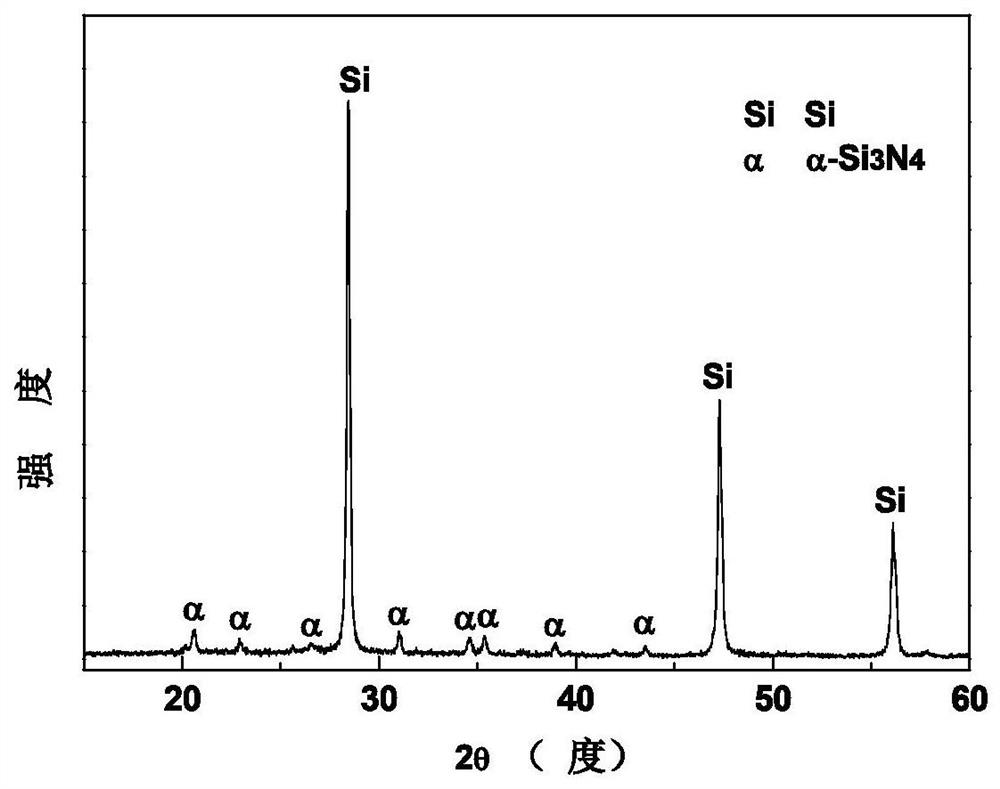

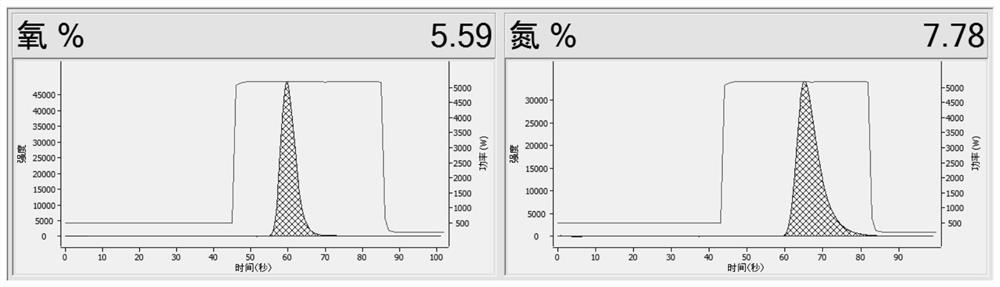

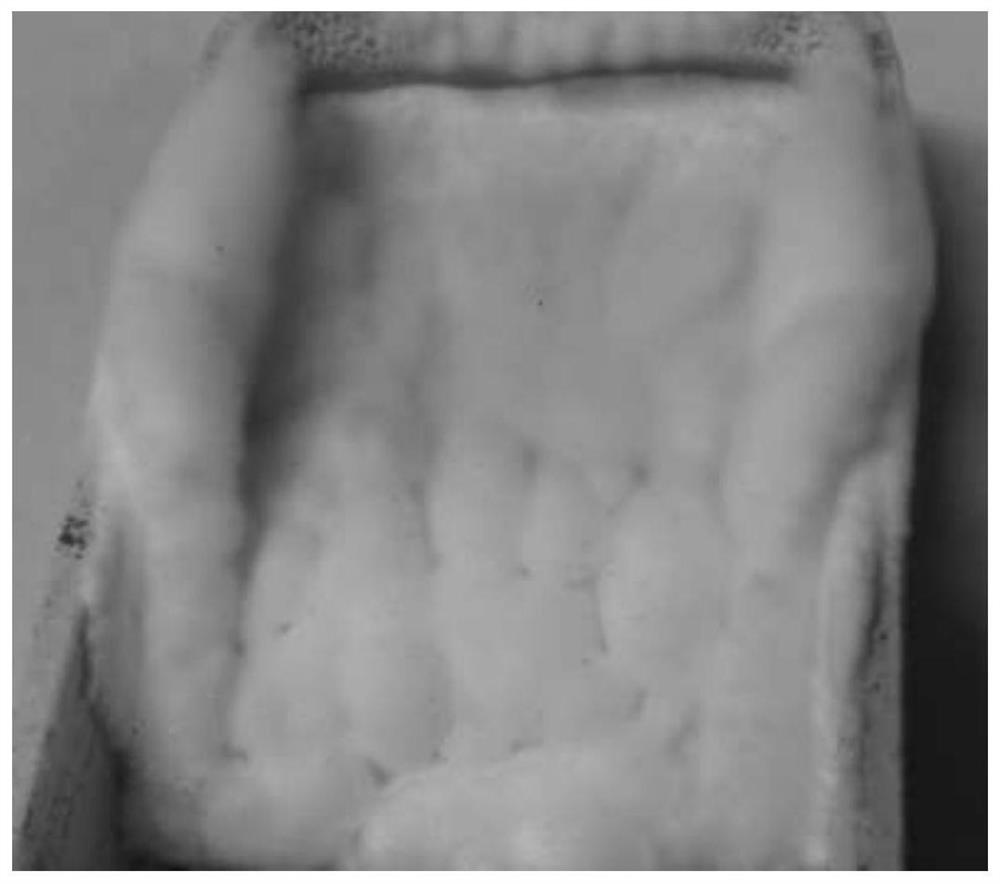

Embodiment 1

[0037](1) Loosely pack silicon powder with an average particle size of 1.96 μm in a silicon nitride sagger with a loose thickness of 20 mm, and place it in the uniform temperature zone of the atmosphere furnace;

[0038] (2) Exhaust gas with a purity of 99.99% ammonia at a flow rate of 100ml / min for 30 minutes, raise the temperature to 1280°C at a rate of 5°C / min, and keep it warm for 1 hour for oxidation and nitriding pretreatment; then the ammonia valve Closed, and simultaneously open nitrogen with a purity of 99.99%, argon with a purity of 99.999%, and hydrogen with a purity of 99.9999%, and the gas flow ratio is N 2 :Ar:H 2 =10:85:5ml / min, keep warm at 1280°C for 6 hours; then rise to 1300°C at a rate of 0.1°C / min, the gas flow ratio is N 2 :Ar:H 2 =20:75:5ml / min, keep warm at 1300°C for 4 hours; then rise to 1320°C at a rate of 0.5°C / min, the gas flow ratio is N 2 :Ar:H 2 =30:65:5ml / min, keep warm at 1320°C for 8 hours; then rise to 1340°C at a rate of 1°C / min, the ga...

Embodiment 2

[0043] (1) Loosely pack silicon powder with an average particle size of 0.78 μm in a high-purity corundum sagger with a loose thickness of 40 mm, and place it in the uniform temperature zone of the atmosphere furnace;

[0044] (2) Exhaust gas at a flow rate of 99.999% ammonia at 100ml / min for 20 minutes, rise to 1250°C at a heating rate of 2°C / min, and keep warm for 5 hours for oxidation and nitriding pretreatment; then high-purity ammonia The gas valve is closed, and nitrogen with a purity of 99.99%, argon with a purity of 99.9999%, and hydrogen with a purity of 99.99% are opened at the same time, and the gas flow ratio is N 2 :Ar:H 2 =15:80:5ml / min, keep warm at 1250°C for 5 hours; then rise to 1300°C at a rate of 0.2°C / min, the gas flow ratio is N 2 :Ar:H 2 =30:65:5ml / min, keep warm at 1300°C for 4 hours; then rise to 1330°C at a rate of 0.5°C / min, the gas flow ratio is N 2 :Ar:H 2 =55:40:5ml / min, keep warm at 1330°C for 4 hours; then rise to 1350°C at a rate of 1°C / min...

Embodiment 3

[0048] (1) Loosely pack silicon powder with an average particle size of 2.25 μm in a silicon carbide sagger with a loose thickness of 60 mm, and place it in the uniform temperature zone of the atmosphere furnace;

[0049] (2) Exhaust gas at a flow rate of 99.9999% ammonia 100ml / min for 60 minutes, rise to 1240°C at a heating rate of 6°C / min, and keep warm for 2 hours for oxidation and nitriding pretreatment; then high-purity ammonia The gas valve is closed, and nitrogen with a purity of 99.9999%, argon with a purity of 99.999% and hydrogen with a purity of 99.999% are opened at the same time, and the gas flow ratio is N 2 :Ar:H 2 =25:70:5ml / min, keep warm at 1240°C for 8 hours; then rise to 1280°C at a rate of 0.1°C / min, the gas flow ratio is N 2 :Ar:H 2 =35:60:5ml / min, keep warm at 1280°C for 4 hours; then rise to 1320°C at a rate of 0.1°C / min, the gas flow ratio is N 2 :Ar:H 2 =50:45:5ml / min, keep warm at 1320°C for 4 hours; then rise to 1340°C at a rate of 0.5°C / min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com