Polypyrrole hydrogel with controllable morphology and preparation method thereof and application of polypyrrole hydrogel to supercapacitor

A hydrogel and gel technology, which is applied in the field of novel polypyrrole hydrogels, can solve the problems of reducing the biocompatibility of hydrogels, decreasing electrical conductivity and the like, and achieves obvious redox performance, low cost and simple preparation method. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

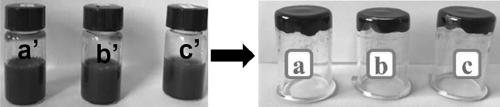

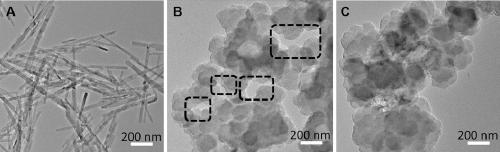

[0031] Example 1: 0.6 mmol of pyrrole monomer was ultrasonically dispersed in 1 mL of isopropanol for 10 minutes, labeled as A stock solution; the strong oxidant APS and crosslinking agent TCPP were ultrasonically dispersed in 1 mL of deionized water in succession, where APS The concentration is 0.3 molL -1 , the amount of TCPP cross-linking agent substance is 0.015 mmol, and the B stock solution is obtained; both the A and B stock solutions are placed in the refrigerator at 4 °C for 10 minutes, and then the B solution is quickly poured into the A solution, and the manual quick vibration is passed. A one-step in situ cross-linking polymerization strategy was used to form a conductive polymer hydrogel, which was left to stand for 3 hours, and the prepared gel was alternately soaked in distilled water and ethanol for 48 hours; then freeze-dried, and the obtained product was used for TEM testing. The results showed that when the molar ratio of Py monomer to cross-linking agent TC...

Embodiment 2

[0032] Example 2: 0.6 mmol of pyrrole monomer was ultrasonically dispersed in 1 mL of isopropanol for 10 minutes, labeled as A stock solution; the strong oxidant APS and crosslinking agent TCPP were ultrasonically dispersed in 1 mL of deionized water in succession, where APS The concentration is 0.3 molL -1, the amount of TCPP cross-linking agent substance was 0.0075 mmol, and the B stock solution was obtained; both the A and B stock solutions were placed in the refrigerator at 4 °C for 10 minutes, and then the B solution was quickly poured into the A solution, and the manual quick vibration was passed. A one-step in situ cross-linking polymerization strategy was used to form a conductive polymer hydrogel, which was left to stand for 3 hours, and the prepared gel was alternately soaked in distilled water and ethanol for 48 hours; then freeze-dried, and the obtained product was used for TEM testing. The results show that when the molar ratio of Py monomer to cross-linking agent...

Embodiment 3

[0033] Example 3: 0.6 mmol of pyrrole monomer was ultrasonically dispersed in 1 mL of isopropanol for 10 minutes, labeled as A stock solution; the strong oxidant APS and crosslinking agent TCPP were ultrasonically dispersed in 1 mL of deionized water in succession, where APS The concentration is 0.3 molL -1 , the amount of the TCPP cross-linking agent is 0.001875 mmol, to the B stock solution; put the A and B stock solutions in the refrigerator at 4 ℃ for 10 minutes, quickly pour the B solution into the A solution, and shake it manually , a conductive polymer hydrogel was formed by a one-step in situ cross-linking polymerization strategy. After standing for 3 hours, the prepared gel was alternately soaked in distilled water and ethanol for 48 hours; then freeze-dried, and the obtained product was used for TEM testing. The results showed that when the molar ratio of Py monomer to cross-linking agent TCPP was 320 / 1, the morphology of the obtained hydrogel was irregular nanospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com