Composite electrolyte sheet, preparation method thereof and solid battery

A composite electrolyte and electrolyte sheet technology, which is applied in the field of solid-state batteries, composite electrolyte sheets and their preparation, can solve the problems of changing electrode/solid electrolyte interface contact conditions, affecting battery energy density and power density, and reducing the capacity of all-solid-state batteries. Achieve the effect of being suitable for large-scale application, improving interface contact, improving cycle performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

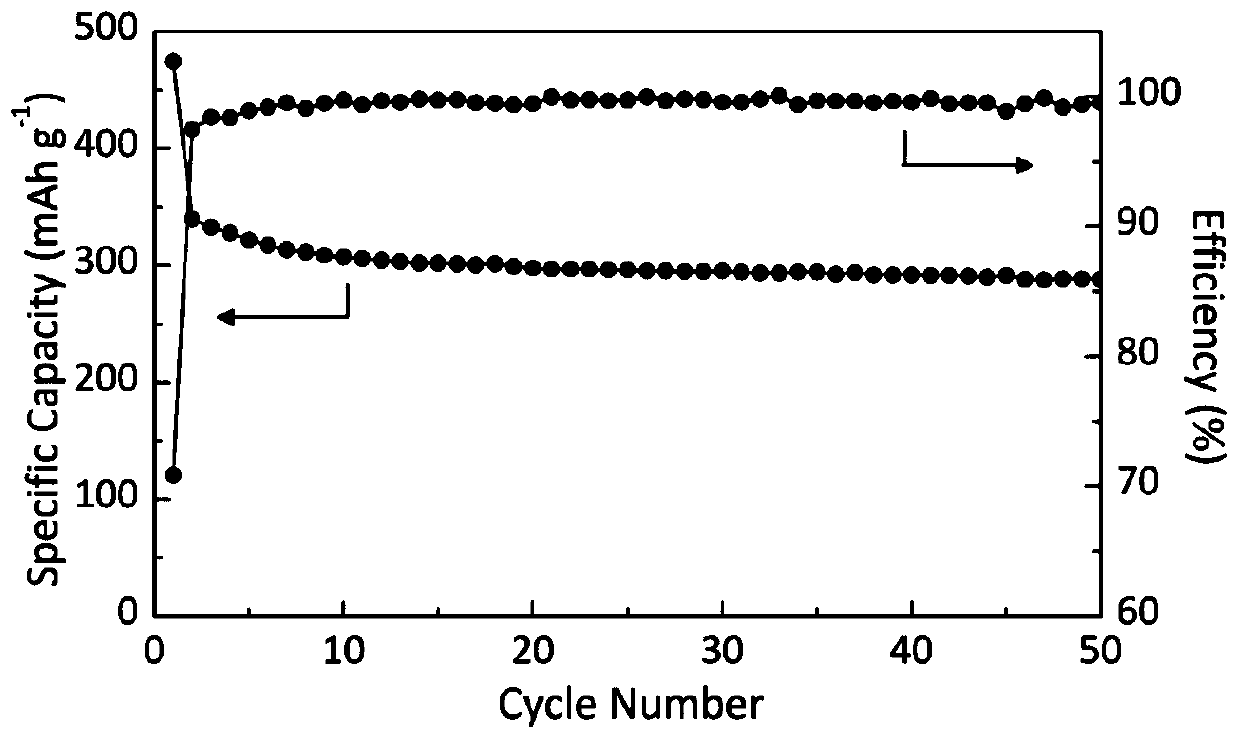

[0077] Polish the surface of NASICON solid electrolyte sheets with a thickness of 1mm, wash them in ethanol and dry them for later use. Dissolve polyvinyl alcohol in water and stir for 12 hours until uniform to obtain a polyvinyl alcohol solution with a concentration of 0.1 mol / L. The above-mentioned polyvinyl alcohol solution was evenly coated on the surface of the above-mentioned solid electrolyte sheet with a coating thickness of 0.15 mm, and dried at 80° C. for 12 hours. The above-mentioned solid electrolyte sheet coated with polyvinyl alcohol solution was placed in an argon atmosphere, and sintered at 500° C. for 2 hours to be carbonized to obtain a composite electrolyte sheet and complete the preparation of the carbon-modified layer.

[0078] The cathode material FeS 2 , NASICON solid electrolyte powder, conductive agent Super P, and binder EC are mixed according to the mass ratio of 55:20:15:10, and terpineol is added as a solvent to make positive electrode slurry. Ev...

Embodiment 2

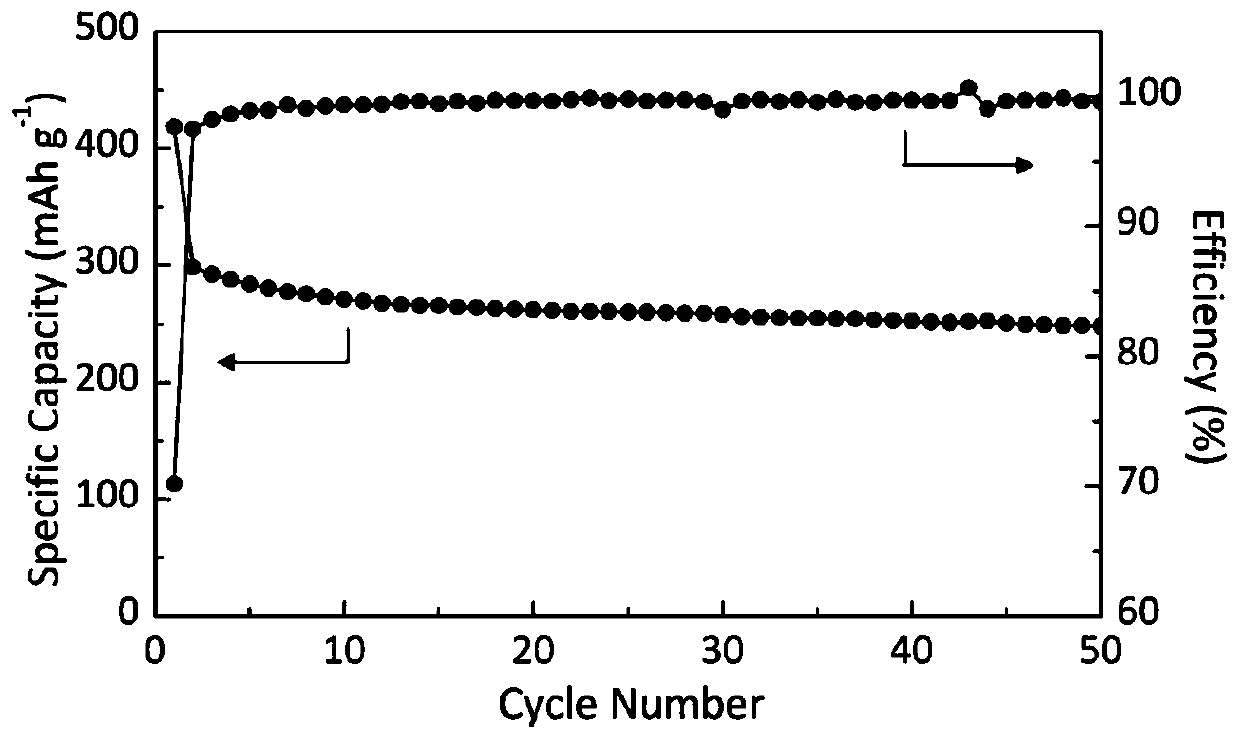

[0081] Polish the surface of NASICON solid electrolyte sheets with a thickness of 0.5mm, wash them in ethanol and dry them for later use. Dissolve polyvinylidene fluoride in NMP and stir for 12 hours until uniform to obtain a polyvinylidene fluoride solution with a concentration of 0.2 mol / L. The above-mentioned polyvinylidene fluoride solution was evenly coated on the surface of the above-mentioned solid electrolyte sheet with a coating thickness of 0.2 mm, and dried at 80° C. for 12 hours. The above-mentioned solid electrolyte sheet coated with polyvinylidene fluoride solution was placed in an argon atmosphere, and sintered at 600° C. for 3 hours to be carbonized to obtain a composite electrolyte sheet and complete the preparation of the carbon-modified layer.

[0082] The cathode material FeS 2 , NASICON solid electrolyte powder, conductive agent acetylene black, and binder PVDF are mixed according to the mass ratio of 50:20:15:15, NMP is added as a solvent, and mixed to f...

Embodiment 3

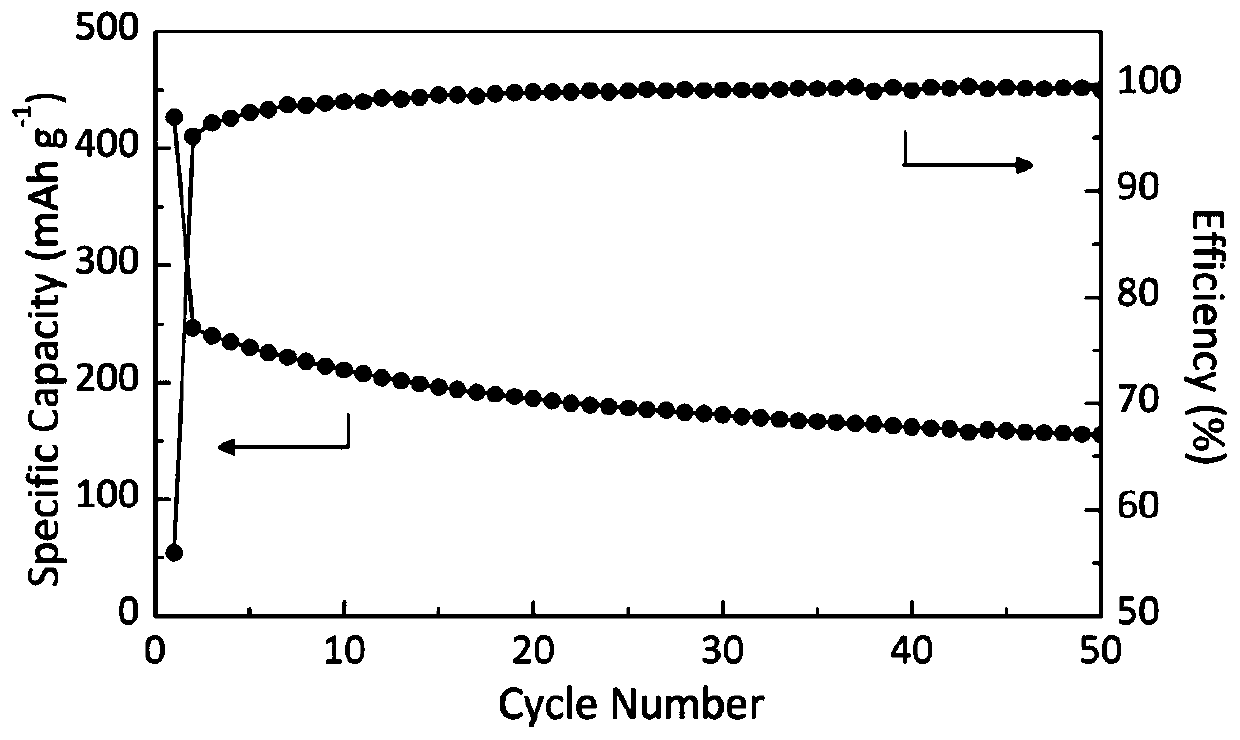

[0085] Polish the surface of NASICON solid electrolyte sheets with a thickness of 0.8mm, wash them in ethanol and dry them for later use. Dissolve ethyl cellulose in terpineol and stir for 6 hours until uniform, to obtain an ethyl cellulose solution with a concentration of 0.05 mol / L. The above-mentioned ethyl cellulose solution was uniformly coated on the surface of the above-mentioned solid electrolyte sheet to a thickness of 0.3 mm, and dried at 80° C. for 12 hours. The above-mentioned solid electrolyte sheet coated with the ethyl cellulose solution was placed in an argon atmosphere, and sintered at 700° C. for 1 hour to be carbonized to obtain a composite solid electrolyte sheet and complete the preparation of the carbon-modified layer.

[0086] The cathode material WS 2 , NASICON solid electrolyte powder, conductive agent acetylene black, and binder CMC are mixed according to the mass ratio of 45:15:20:20, NMP is added as a solvent, and mixed to form a positive electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com