Functional edible mushroom seasoning powder and preparation method thereof

A technology of edible fungus and seasoning powder, which is applied in the direction of food ingredients as taste improvers, applications, food science, etc., to achieve the effects of easy use, rich nutrients, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

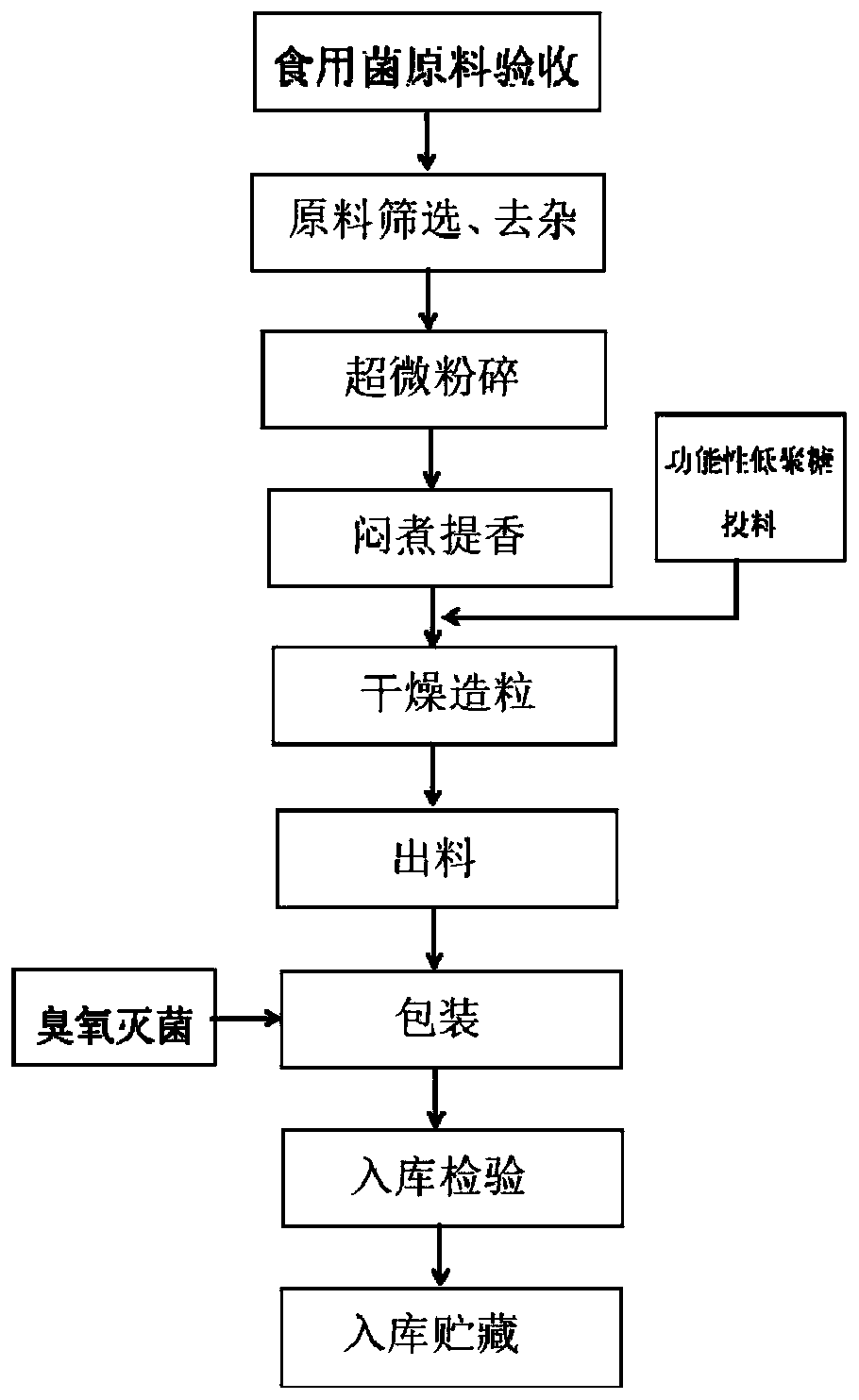

Method used

Image

Examples

Embodiment 1

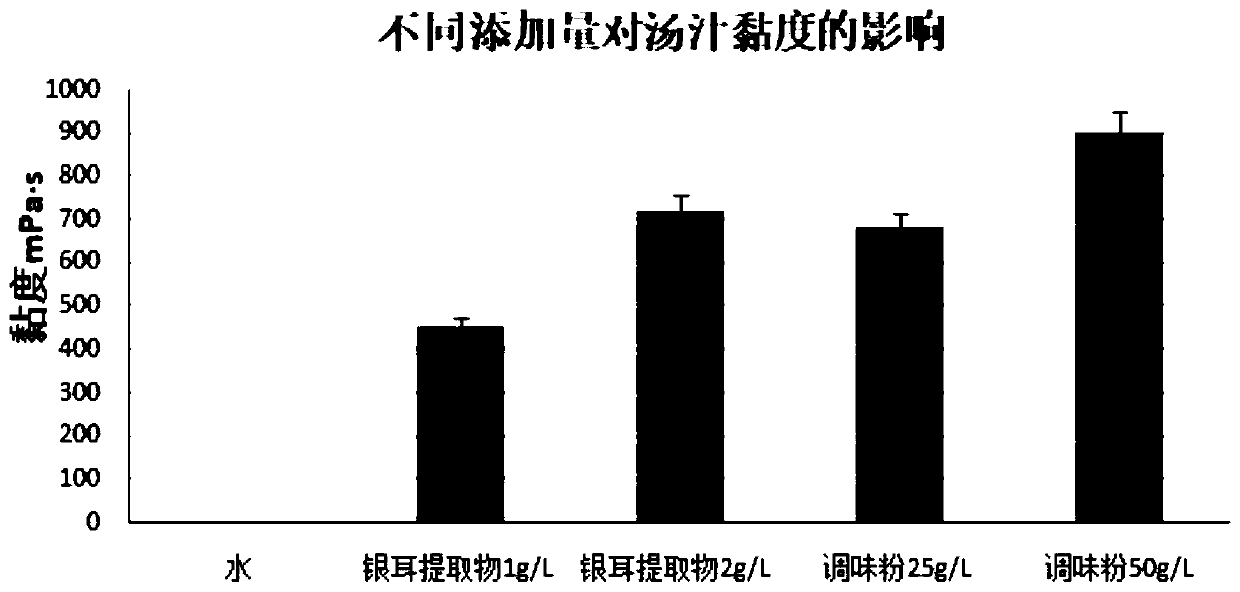

[0042] One, the preparation of white fungus extract

[0043] 1. Take the dried tremella fruiting body, pulverize it with a pulverizer, and pass through a 40-mesh sieve;

[0044] ② Add 10 times the volume of distilled water for ultrasonication, the ultrasonic power is 400W, and the ultrasonic time is 30min;

[0045] ③ Extract in boiling water for 2 hours, then centrifuge (8000rpm / min, 10min) after cooling, and collect the supernatant;

[0046] ④Concentrate under reduced pressure at 50°C to an appropriate volume, freeze-dry after pre-freezing for 5 hours, take it out and grind it into powder to obtain Tremella extract.

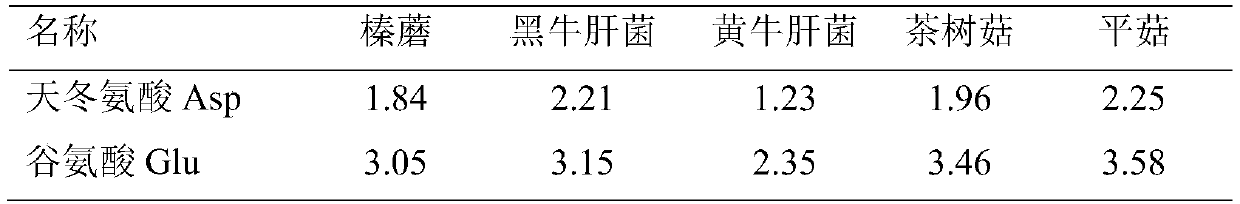

[0047] 2. Preparation of functional edible mushroom seasoning powder

[0048] Composition of raw materials in the following parts by weight: 10 parts of hazel mushroom, 10 parts of tea tree mushroom, 3 parts of yellow boletus, 3 parts of black boletus, 5 parts of oyster mushroom, 5 parts of poria cocos, 1 part of tiger's palm fungus, and bamboo fungus 2 parts...

Embodiment 2

[0064] One, the preparation of white fungus extract

[0065] 1. Take the dried tremella fruiting body, pulverize it with a pulverizer, and pass through a 40-mesh sieve;

[0066] ②Add 10 times the volume of distilled water for ultrasonication, the ultrasonic power is 400W, and the ultrasonic time is 60min;

[0067] ③Extract in boiling water for 2 hours, then centrifuge (1000rpm / min, 10min) after cooling, and collect the supernatant;

[0068] ④Concentrate under reduced pressure at 50°C to an appropriate volume, freeze-dry after pre-freezing for 6 hours, take it out, and grind it into powder to obtain the white fungus extract.

[0069] 2. Preparation of functional edible mushroom seasoning powder

[0070] Composition of raw materials in the following parts by weight: 12 parts of hazel mushroom, 12 parts of tea tree mushroom, 2 parts of yellow boletus, 2 parts of black boletus, 4 parts of oyster mushroom, 4 parts of poria cocos, 1 part of tiger palm, and bamboo fungus 2 parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com