Modification method of active metal catalyst, and application of modified active metal catalyst

An active metal and catalyst technology, applied in the field of nano-semiconductor composite material preparation, can solve the problems of large Ag particle size, easy agglomeration, easy deactivation, cumbersome and other problems, and achieves the effects of simple modification method, improved catalytic performance and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) The nanomaterial CeO 2 Nanorods in 3 mL of 5 mg / mL FeCl 2 Ultrasound in the solution for 30min to make CeO 2 The surface is fully activated.

[0047] (2) Disperse the solution obtained in step (1) in 3 mL of 0.1 mg / mL AgNO 3 solution, aged for 5h and then centrifuged.

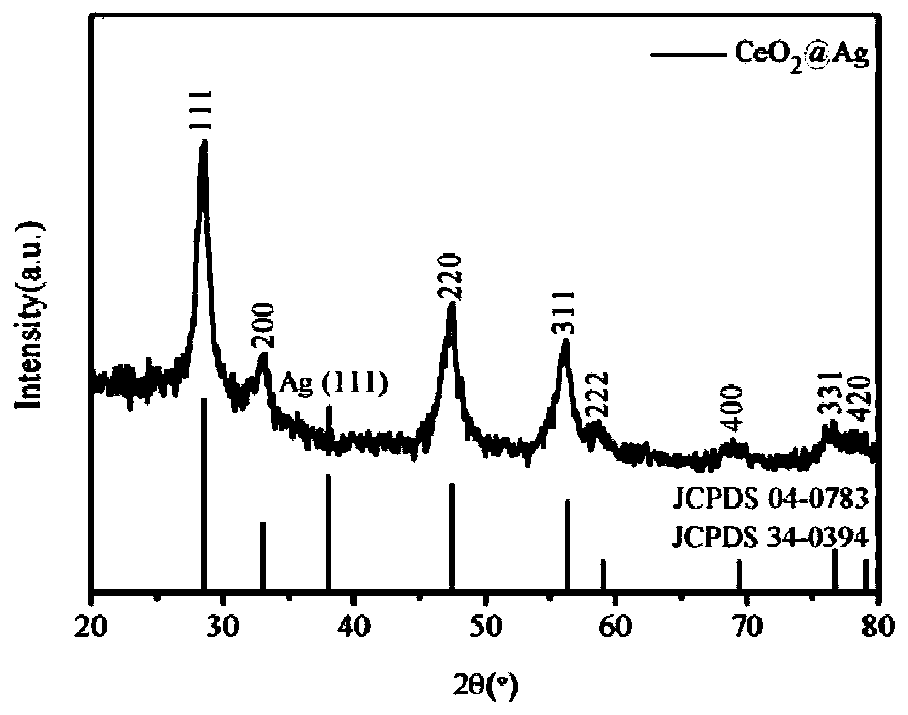

[0048] (3) After rinsing the compound obtained in step (2) several times with deionized water, dry it to obtain CeO 2 @Ag nano-semiconductor composite materials, XRD analysis of nano-semiconductor composite materials such as figure 1 As shown, HRTEM with nanosemiconductor composites dispersed in ethanol as figure 2 As shown, after ICP detection, the loading amount of Ag is 5.42wt%.

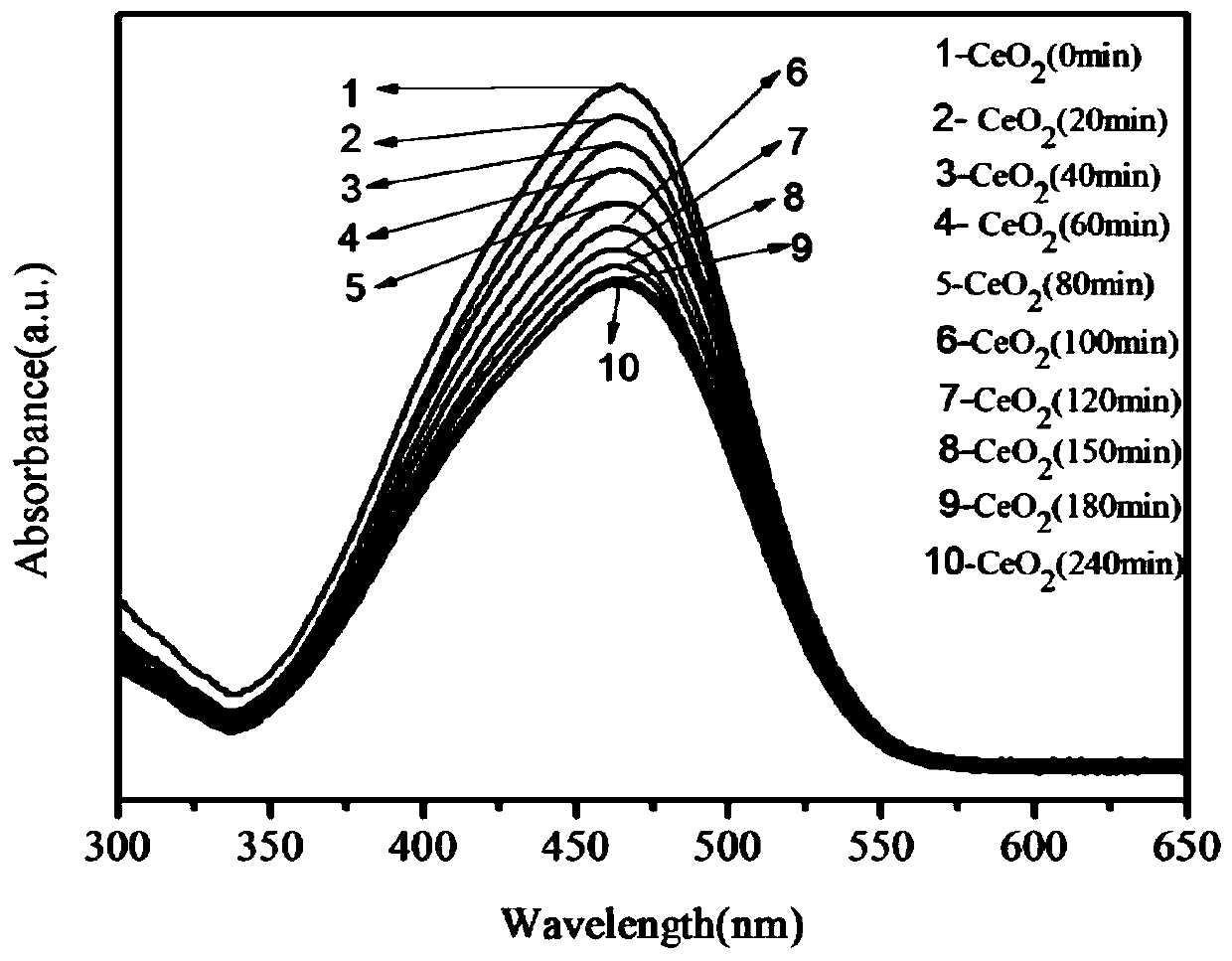

[0049] (4) will take 15mg CeO respectively 2 Nanorods, CeO 2 Each of the @Ag nanosemiconductor composites was dissolved in 50 mL of methyl orange (5 mg / L) solution.

[0050] (5) Shake the solution in step (4) for 10 min in the dark, so that the photocatalyst-pollutant molecule reaches an adsorption-desorption e...

Embodiment 2

[0053] (1) The nanomaterial CeO 2 Nanorods in 3 mL of 5 mg / mL SnCl 2 Ultrasound in the solution for 30min to make CeO 2 The surface is fully activated.

[0054] (2) Disperse the solution obtained in step (1) in 3 mL of 10 mg / mL AgNO 3 solution, aged for 10 h and then centrifuged.

[0055] (3) After rinsing the compound obtained in step (2) several times with deionized water, dry it to obtain CeO 2 @Ag nano-semiconductor composite material, HRTEM dispersed in ethanol as image 3 shown.

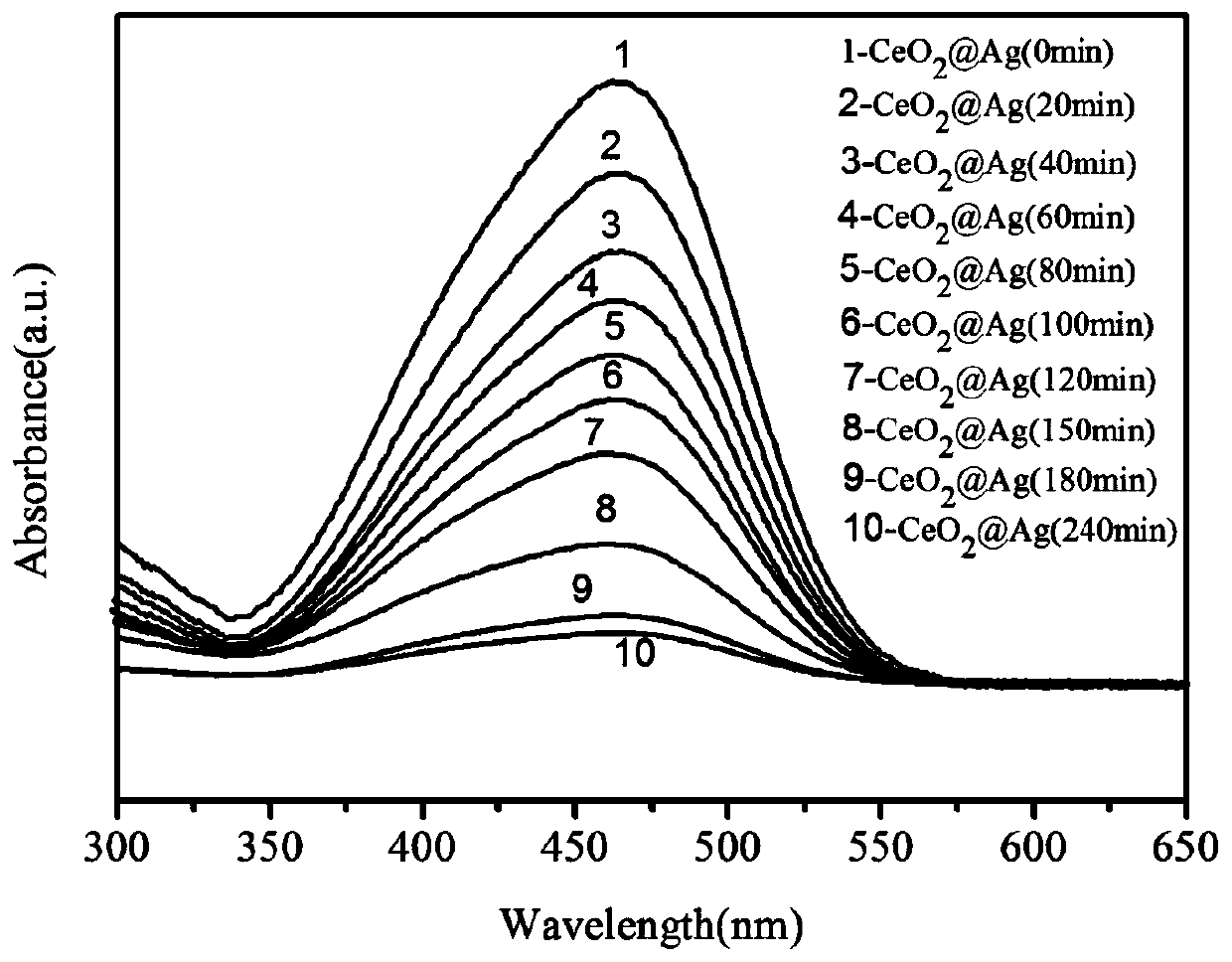

[0056] (4) CeO 2 15 mg of @Ag nano-semiconductor composite materials were dissolved in 50 mL of methyl orange (5 mg / L) solution.

[0057] (5) Shake the solution in step (4) for 10 min in the dark, so that the photocatalyst-pollutant molecule reaches an adsorption-desorption equilibrium in the aqueous solution.

[0058] (6) The solution in step (5) was irradiated under a 200W xenon lamp, and every 20 minutes, centrifuged to take 4 mL of the supernatant and measured the absorbance with a ...

Embodiment 3

[0061] (1) The nanomaterial CeO 2 Nanorods in 3 mL of 8 mg / mL AlCl 3 Ultrasound in the solution for 50min to make CeO 2 The surface is fully activated.

[0062] (2) Disperse the solution obtained in step (1) in 3 mL of 50 mg / mL AgNO 3 solution, aged for 15 hours and then centrifuged.

[0063] (3) After rinsing the compound obtained in step (2) several times with deionized water, dry it to obtain CeO 2 @Ag nano-semiconductor composites.

[0064] (4) CeO 2 15 mg of @Ag nano-semiconductor composite materials were dissolved in 50 mL of methyl orange (5 mg / L) solution.

[0065] (5) Shake the solution in step (4) for 10 min in the dark, so that the photocatalyst-pollutant molecule reaches an adsorption-desorption equilibrium in the aqueous solution.

[0066] (6) The solution in step (5) was irradiated under a 200W xenon lamp, and every 20 minutes, centrifuged to take 4 mL of the supernatant and measured the absorbance with a UV-Vis spectrophotometer.

[0067] In the above (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com