Quantum dot luminescence encoding microsphere with precisely designable encoding signals

A technology of encoding signal and fluorescent encoding is applied in the field of preparation and application of micro-nano materials, which can solve the problems that have not been seen yet, and the preparation process of encoded microspheres is complicated, so as to reduce technical barriers and preparation costs, and the preparation method is simple and efficient, and widely used. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

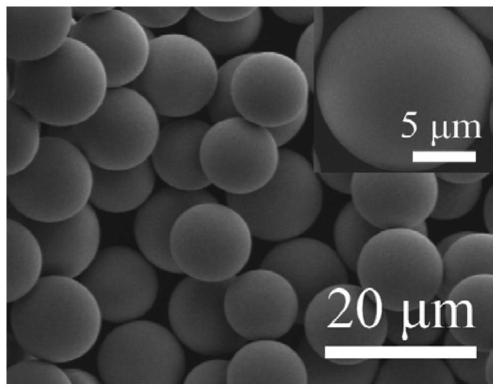

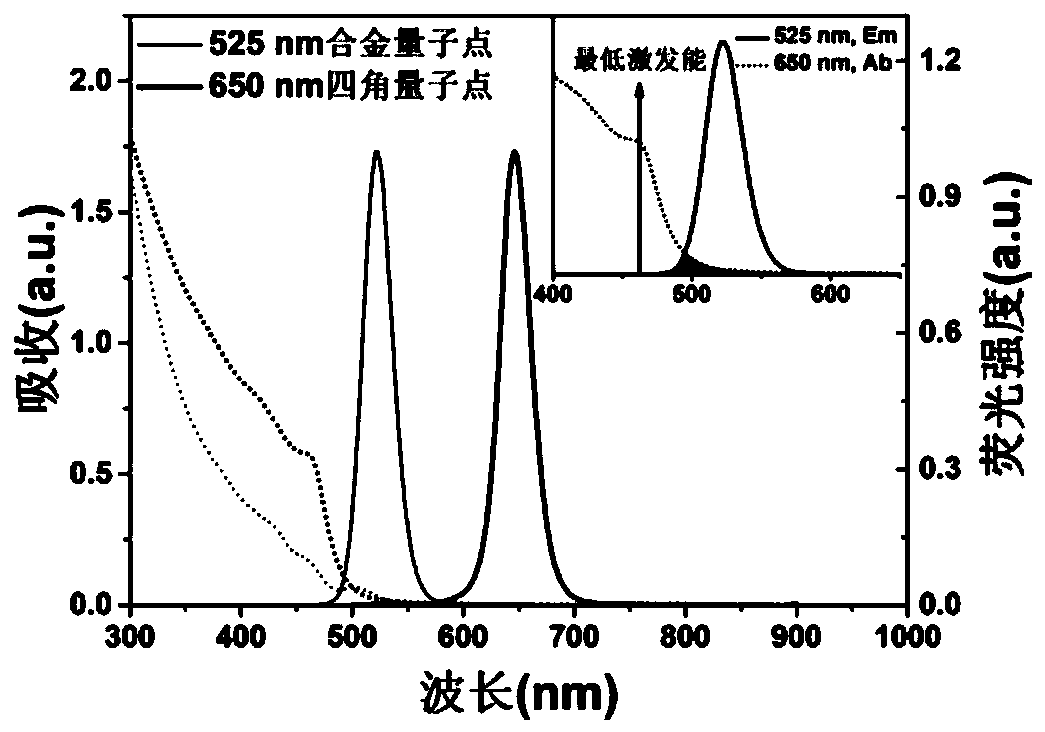

[0036] The quantum dot fluorescent coded microspheres prepared in this embodiment that can be precisely designed for coding signals are CdSe / CdS quadruped quantum dots / PSMA fluorescent coded microspheres, wherein the quantum dots with large Stokes shifts are CdSe / CdS quadruped quantum dots. Point, the polymer is styrene-maleic anhydride copolymer (PSMA), and the preparation method is the SPG film emulsification-emulsion solvent evaporation method, and the specific preparation steps are:

[0037] Step 1, 0.1mg of CdSe / CdS tetrapod quantum dots and 0.25g of styrene-maleic anhydride copolymer (PSMA) were dissolved in 4mL of toluene to form a dispersed phase;

[0038] Step 2, the sodium dodecyl sulfate (SDS) of 1g is dissolved in the ultrapure water of 200mL, forms continuous phase;

[0039] Step 3, using an SPG membrane with a pore size of 5 μm, under the nitrogen pressure of 2KPa and the shear force of the continuous phase, a uniform and stable oil-in-water emulsion is prepared;...

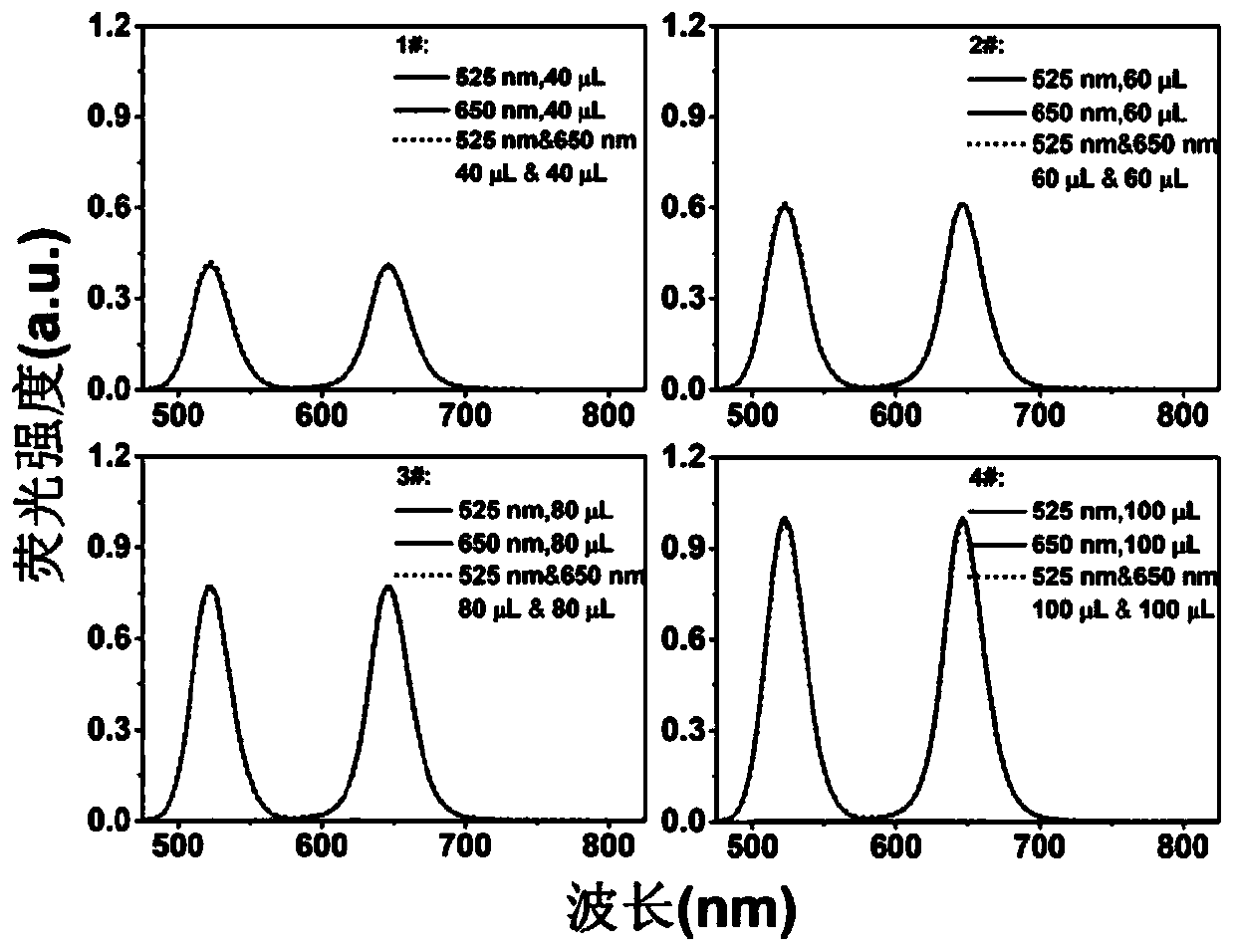

Embodiment 2

[0044] The quantum dot fluorescent coded microspheres prepared in this embodiment that can be precisely designed for coding signals are Mn:ZnSe / ZnS quantum dots / PSMA fluorescent coded microspheres, wherein the quantum dots with a large Stokes shift are Mn:ZnSe / ZnS quantum dots Point, the polymer is styrene-maleic anhydride copolymer (PSMA), and the preparation method is the SPG film emulsification-emulsion solvent evaporation method, and the specific preparation steps are:

[0045] Step 1, 10 mg of Mn: ZnSe / ZnS quantum dots and 0.5 g of styrene-maleic anhydride copolymer (PSMA) are dissolved in 8 mL of toluene to form a dispersed phase;

[0046] Step 2, the sodium dodecyl sulfate (SDS) of 1g is dissolved in the ultrapure water of 200mL, forms continuous phase;

[0047] Step 3, using an SPG membrane with a pore size of 5 μm, under the nitrogen pressure of 2KPa and the shear force of the continuous phase, a uniform and stable oil-in-water emulsion is prepared;

[0048] Step 4, ...

Embodiment 3

[0051] The quantum dot fluorescent coded microspheres prepared in this embodiment that can be precisely designed for coding signals are Mn:ZnSe / ZnS quantum dots / PSMA fluorescent coded microspheres, wherein the quantum dots with a large Stokes shift are Mn:ZnSe / ZnS quantum dots Point, the polymer is styrene-maleic anhydride copolymer (PSMA), and the preparation method is a microfluidic method, and the specific preparation steps are:

[0052] Step 1, 5mg of Mn:ZnSe / ZnS quantum dots and 0.25g of styrene-maleic anhydride copolymer (PSMA) were dissolved in 4mL of chloroform to form a dispersed phase;

[0053] Step 2, the sodium dodecyl sulfate (SDS) of 1g is dissolved in the ultrapure water of 200mL, forms continuous phase;

[0054] Step 3, using a small droplet microfluidic device with a pore diameter of 5 μm, wherein the flow rate of the continuous phase is 12 nL / min, the flow rate of the dispersed phase is 8 nL / min, and the continuous phase and the dispersed phase are at T Conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com