Near-zero dielectric constant controllable substrate and preparation method thereof

A near-zero dielectric constant technology, applied in the field of near-zero dielectric constant controllable substrates and its preparation, can solve the problems of complex operation and long experimental cycle, and achieve broad application prospects, short process cycle, and short time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

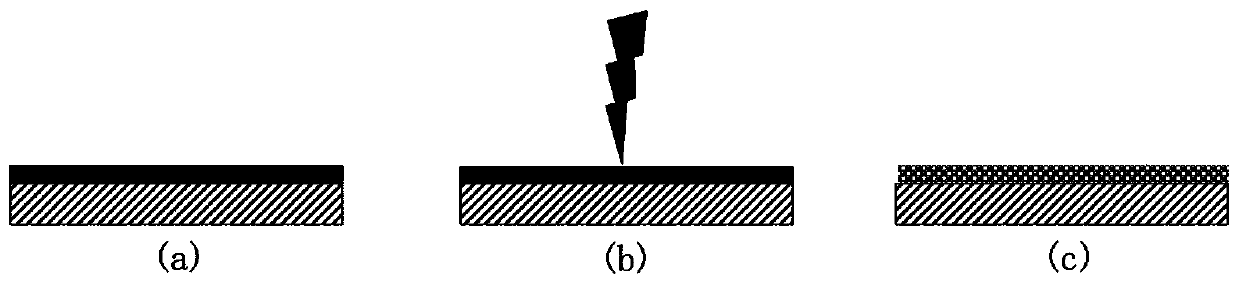

[0028] This embodiment describes the preparation method of a substrate with a controllable near-zero dielectric constant.

[0029] Step 1. Place the clean substrate in the electron beam vacuum evaporation equipment, and deposit a film material with near-zero dielectric constant on the substrate by electron beam evaporation to obtain a transparent and conductive film.

[0030] In this embodiment, indium tin oxide (ITO) with a purity of 99.99% is selected as the film material, and 90wt.% (indium oxide) In 2 o 3 and 10wt.% (tin oxide) SnO 2 composition. A quartz substrate was chosen as the substrate. Keep the vacuum in the electron beam vacuum evaporation equipment below 9.0×10 -4 Pa, deposit ITO on the surface of the quartz substrate to obtain a 300nm thick transparent and conductive ITO film.

[0031] Step 2: In the atmospheric environment, a pulsed laser is used to irradiate the surface of the film with certain laser parameters, so that the film is modified to obtain a su...

Embodiment 2

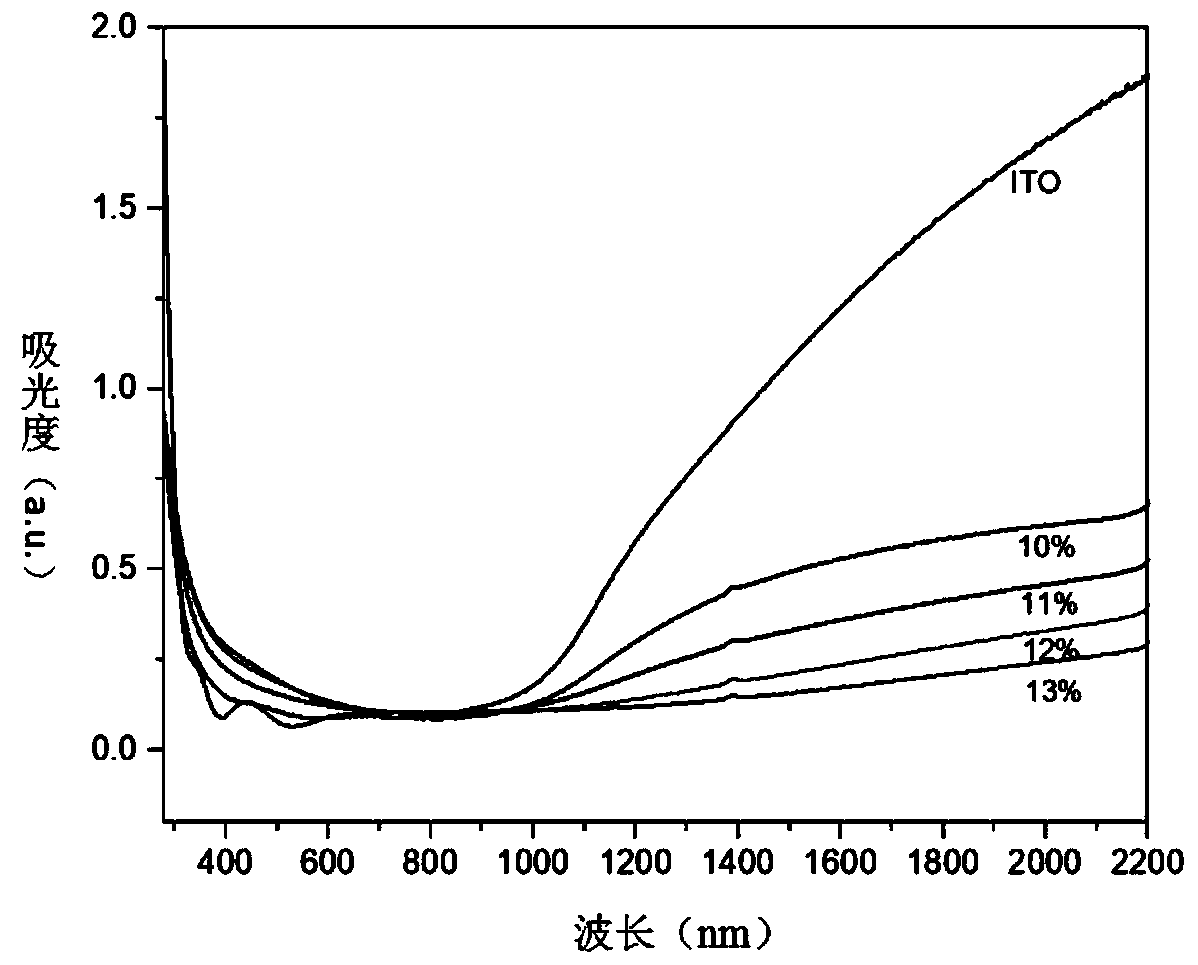

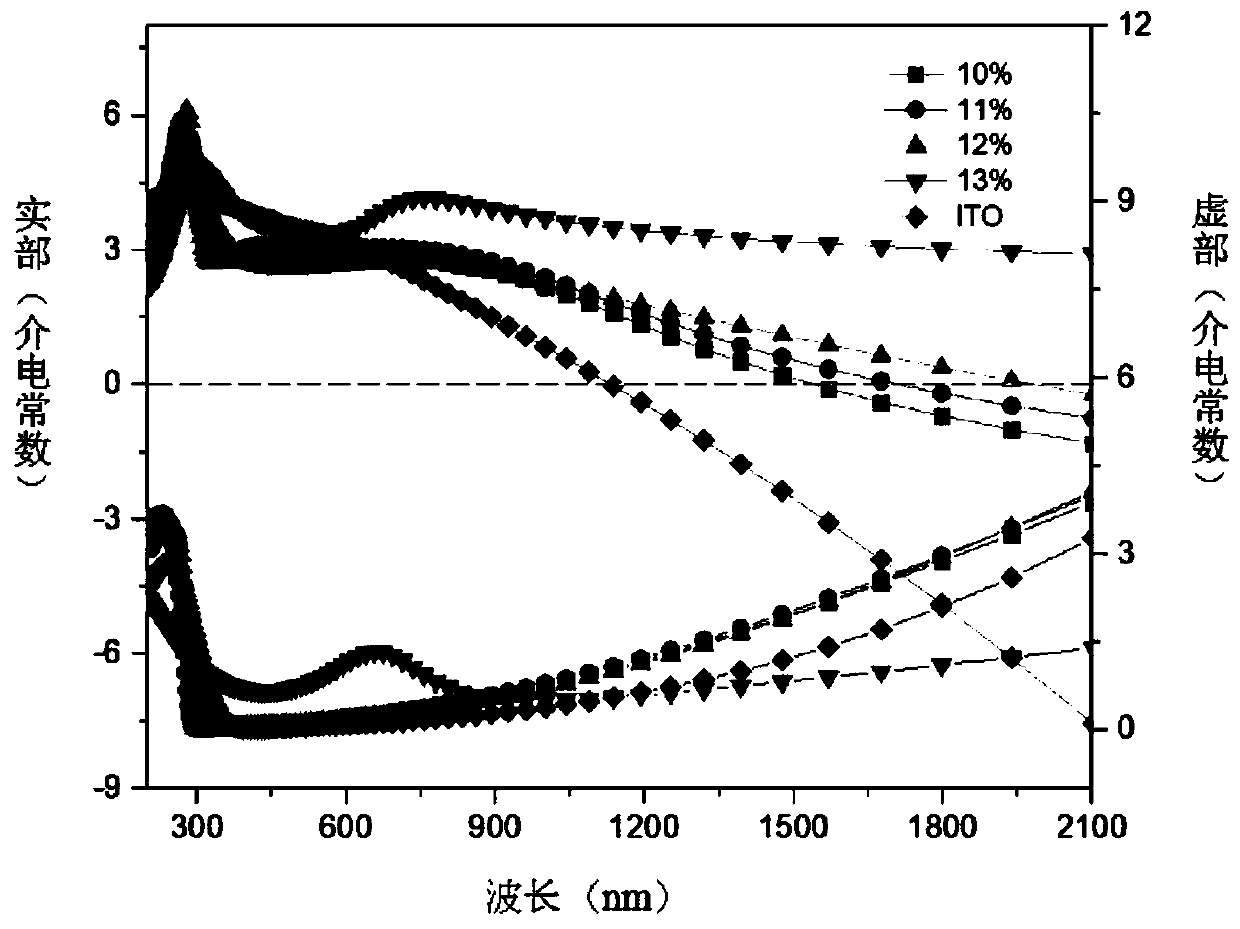

[0034] In this embodiment, except that the laser power used by the 1064 nanosecond pulsed laser is different when irradiating the ITO thin film, the remaining parts are the same as in Embodiment 1, so details are not repeated here. In this embodiment, the laser power is 10% of the total laser power, that is, 2.2w.

Embodiment 3

[0036] In this embodiment, except that the laser power used by the 1064 nanosecond pulsed laser is different when irradiating the ITO thin film, the remaining parts are the same as in Embodiment 1, so details are not repeated here. In this embodiment, the laser power is 12% of the total laser power, that is, 2.4w.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com