Laser cladding device for self-healing of cracks of cladding layer and processing method of laser cladding device

A technology of laser cladding and processing method, applied in the direction of metal material coating technology, coating, etc., can solve the problems of reducing the actual effect of current, unfavorable current density, increase, etc., to improve cladding efficiency, reduce cracking sensitivity, The effect of uniform cladding layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

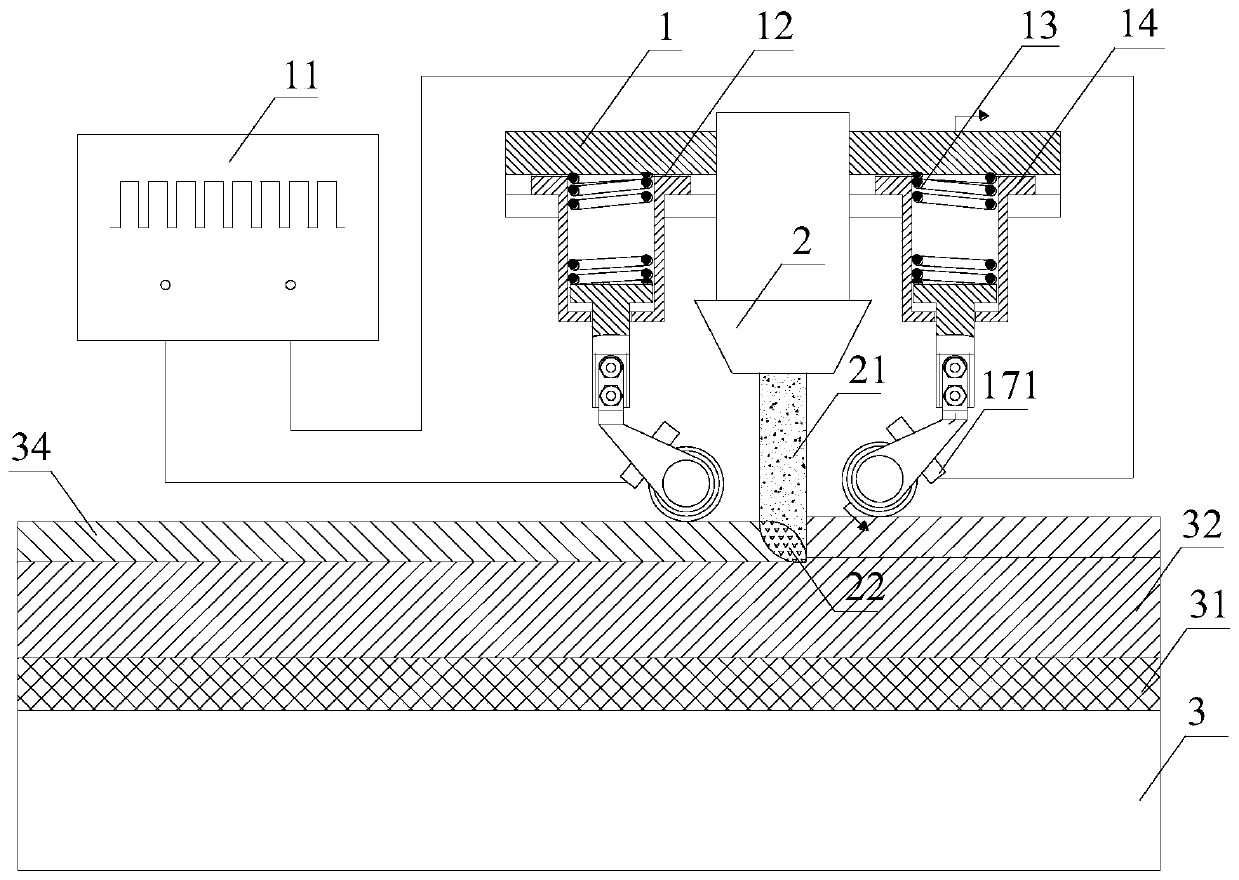

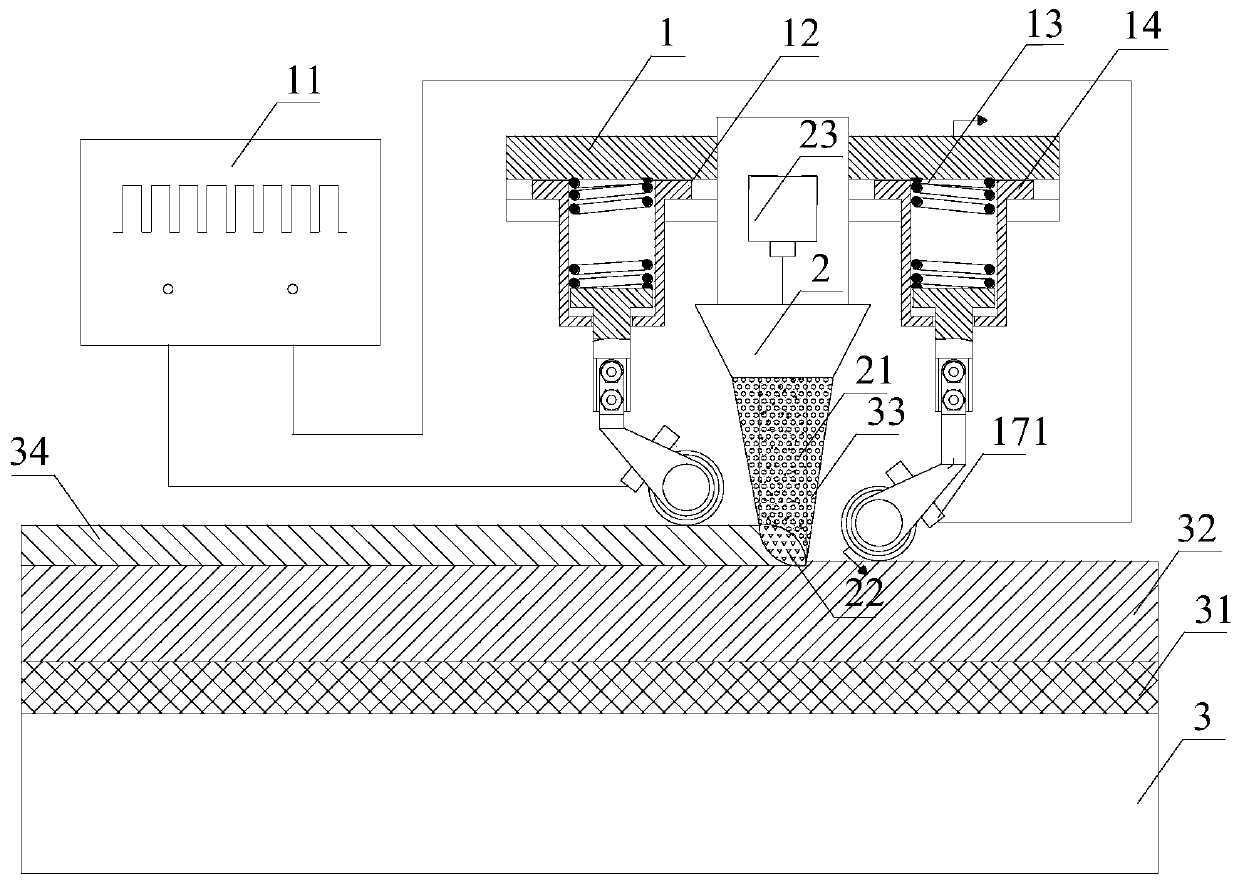

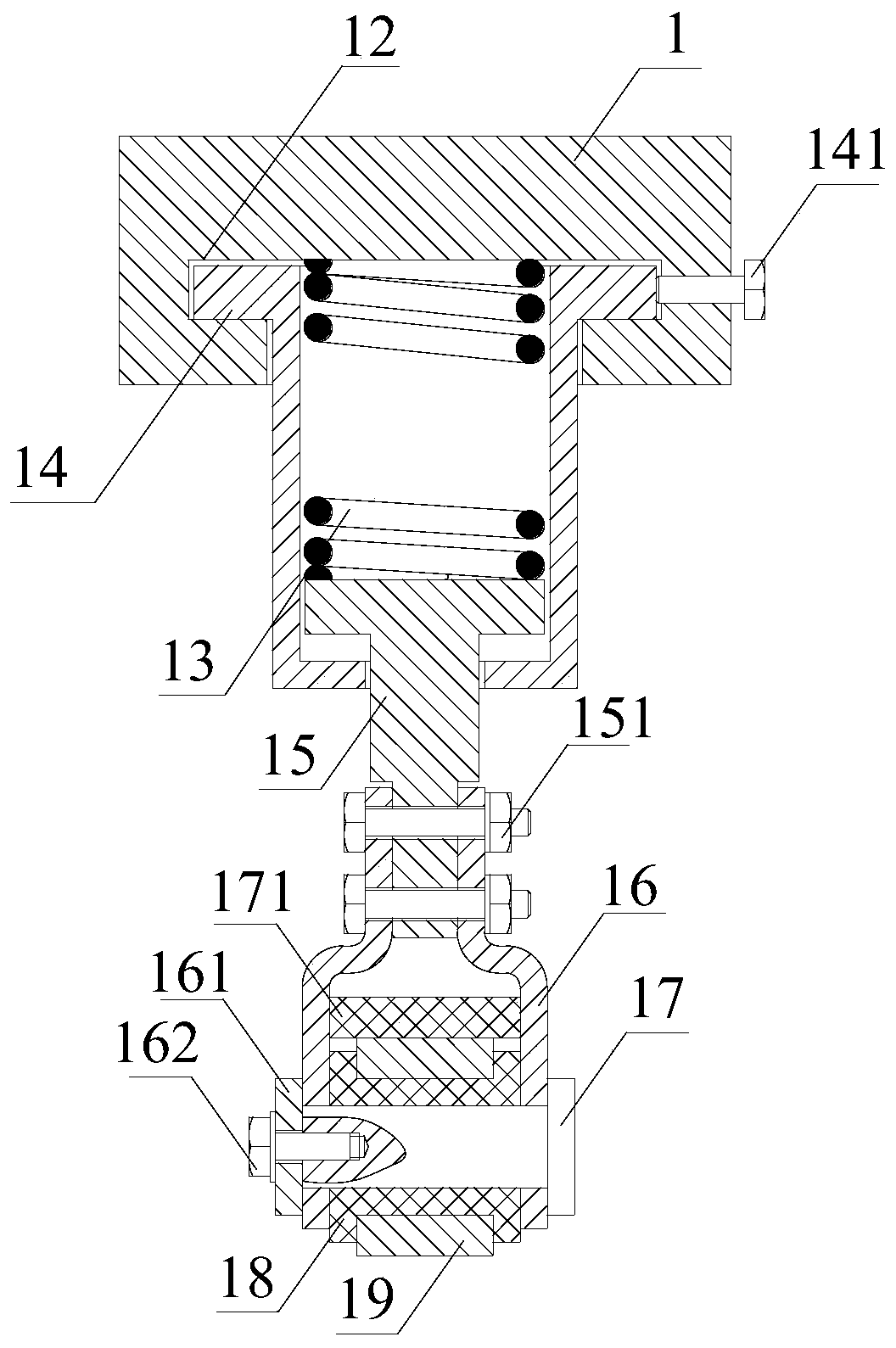

[0044] Such as Figure 1-3As shown, a laser cladding device for self-healing cracks in the cladding layer 34 includes a laser cladding mechanism and a pulse current mechanism. The laser cladding mechanism is arranged above the workbench 3, including The fixed seat 1 and the laser head 2 connected with the fixed seat 1, the laser head 2 is used to emit the laser beam 21, and perform laser cladding on the substrate 32 and the cladding layer 34, and the input end of the laser head 2 is also provided with There is a powder feeder 23, and the powder feeder 23 is used for conveying the powder body 33 to the surface of the base body 32, so that the powder conveying and cladding of the cladding layer 34 can be carried out simultaneously during the laser cladding process.

[0045] The pulse current mechanism includes adjustable electrode assemblies respectively arranged at both ends of the laser cladding mechanism, and the adjustable electrode assembly is connected to the fixed seat 1 ...

Embodiment 2

[0056] This embodiment adopts the laser cladding device for self-healing of cladding layer cracks in the above-mentioned embodiment 1 to prepare Ni60A coating on the surface of 42CrMo substrate, including the following steps:

[0057] Step S1: Select YLS-6000 high-power fiber laser produced by German IPG company and XSL-PF-01B-2 double-silo negative pressure coaxial powder feeder, and carry out coaxial powder feeding laser melting on the surface of 42CrMo alloy structural steel substrate Cover with Ni60A coating, place the insulating plate and the 42CrMo alloy structural steel substrate on the worktable in sequence, and adjust the positions of the pulse current mechanism, the laser cladding mechanism and the workbench;

[0058] Step S2: Set the laser cladding process parameters as follows: spot diameter is 5mm; laser power is 2000W; scanning speed is 5mm s -1 ; Powder feeding rate is 25g·min -1 ;Argon gas is used to protect the molten pool, and the carrier gas volume is 8L mi...

Embodiment 3

[0061] This embodiment is to prepare the MCrAlY coating on the surface of the GH4169 substrate using the laser cladding device for the self-healing of the cladding layer cracks in the above-mentioned embodiment 1, including the following steps:

[0062] Step S1: Select the 3710 atmospheric plasma spraying system produced by Praxair in the United States to spray the MCrAlY bonding layer on the GH4169 substrate. In terms of mass percentage, the composition of the MCrAlY powder is: Ni-20Co-18Cr-15Al-2Y 2 o 3 ; Place the insulation board and the GH4169 substrate in turn on the workbench, and adjust the positions of the pulse current mechanism, the laser cladding mechanism and the workbench;

[0063] Step S2: Select SLCF-X12×25 CO 2 The laser processing machine performs laser cladding, and the laser cladding process parameters are set as the optical power is 850W, the spot diameter is 3mm, and the laser scanning speed is 600mm min -1 , when remelting, blow argon to protect the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com