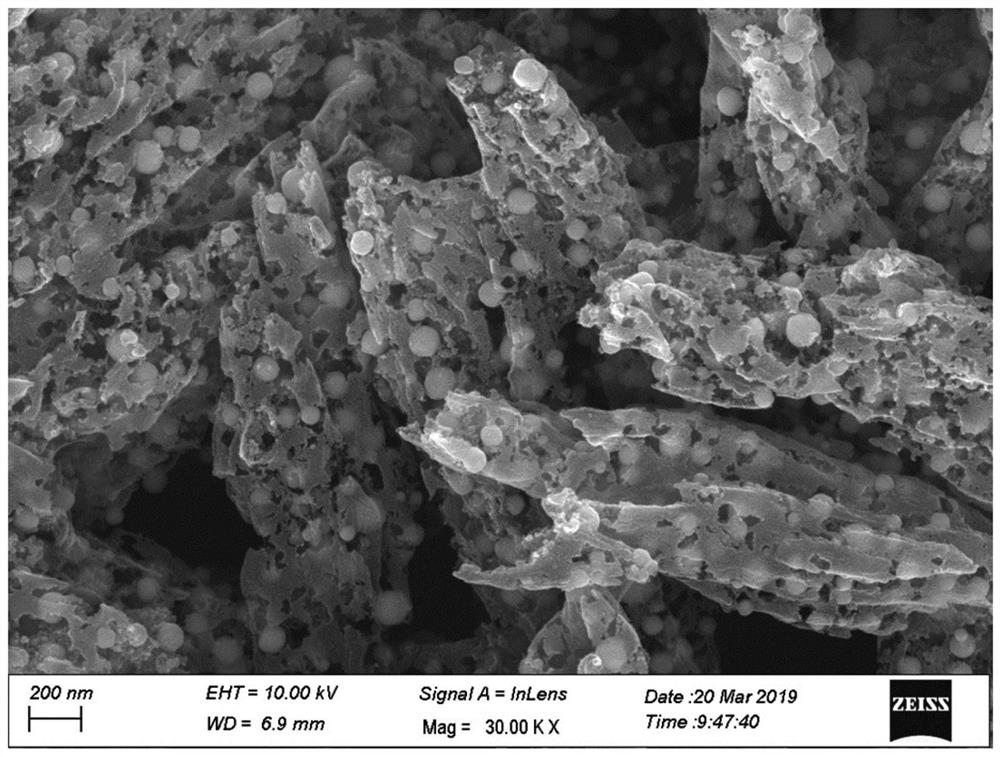

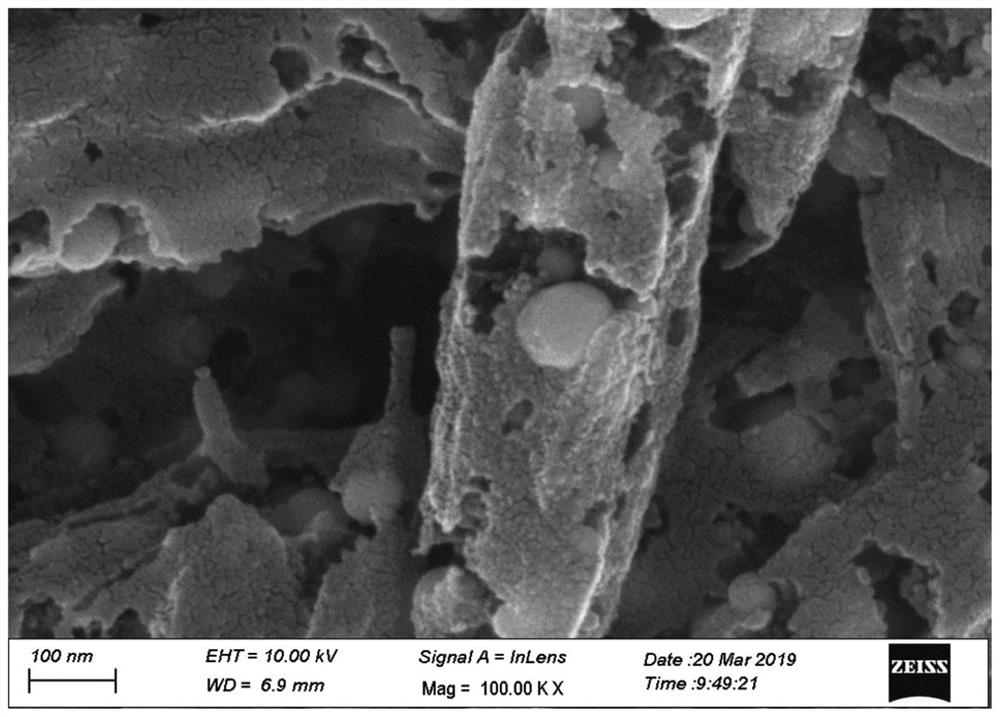

A carbon nanotube-coated cobalt oxide material and its preparation method and application

A technology of carbon nanotubes and cobalt oxide, which is applied in electrochemical generators, textiles, papermaking, structural parts, etc., can solve problems such as poor conductivity, reduced conductivity, and disconnected carbon structures, so as to improve specific capacity and charge and discharge Efficiency, high productivity, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of carbon nanotube-coated cobalt oxide material, comprising the following steps:

[0048] (1) Weigh 0.5239g cobalt nitrate (or cobalt acetate) and 6g PVP into beaker A, add 200mL ultrapure water, stir vigorously, weigh 0.3323g cobalt potassium cyanide and put it in beaker B, add 200mL ultrapure water , stir until the potassium cobalt cyanide is completely dissolved, slowly add the solution in beaker B to beaker A and stir, stir for 30min, and then let stand to obtain a gelatinous mixture, centrifuge the gelatinous mixture, and the rotation speed requires 5500-6000rad / min , the centrifugation time was 5 min. After the first centrifugation, pour out the supernatant liquid, add ultrapure water and repeat the above centrifugation steps for two times, then add ethanol for centrifugation, repeat the above centrifugation steps, and finally obtain a cement-like solid, which is then dried in a vacuum drying box to obtain The solid material was ground for 30...

Embodiment 2

[0059] A preparation method of carbon nanotube-coated cobalt oxide material, comprising the following steps:

[0060] (1) Weigh 0.5239g cobalt nitrate (or cobalt acetate) and 6g PVP into beaker A, add 200mL ultrapure water, stir vigorously, weigh 0.3323g cobalt potassium cyanide and put it in beaker B, add 200mL ultrapure water Water, stir until the potassium cobalt cyanide is completely dissolved, slowly add the solution in beaker B to beaker A and stir, then let stand to obtain a gel-like mixture, centrifuge the gel-like mixture, and pour out the upper layer after the first centrifugation to clarify liquid, add ultrapure water and repeat the above centrifugation steps for two times, then add ethanol for centrifugation, repeat the above centrifugation steps, and finally obtain a colloidal solid, which is then dried in a vacuum drying box, and the obtained solid material is ground for 30min to finally obtain Co- PBA powder;

[0061] (2) Weigh 0.6024g of Co-PBA and drop it int...

Embodiment 3

[0071] A preparation method of carbon nanotube-coated cobalt oxide material, comprising the following steps:

[0072] (1) Weigh 0.5239g cobalt nitrate and 6g PVP into beaker A, add 200mL ultrapure water, stir vigorously, weigh 0.3323g cobalt potassium cyanide and put it in beaker B, add 200mL ultrapure water, stir until cobalt The potassium cyanide is completely dissolved, slowly add the solution in beaker B to beaker A and stir, and then let stand to obtain a gelatinous mixture, centrifuge the gelatinous mixture, pour out the supernatant after the first centrifugation, add ultrapure Repeat the above centrifugation steps with water for two times, then add ethanol for centrifugation, repeat the above centrifugation steps, and finally obtain a mucilage-like solid, which is then put into a vacuum drying oven to dry, and the obtained solid material is ground and finally obtained Co-PBA powder;

[0073] (2) Weigh 0.8217g of Co-PBA and drop it into a mixed solution of 10mL DMF (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com