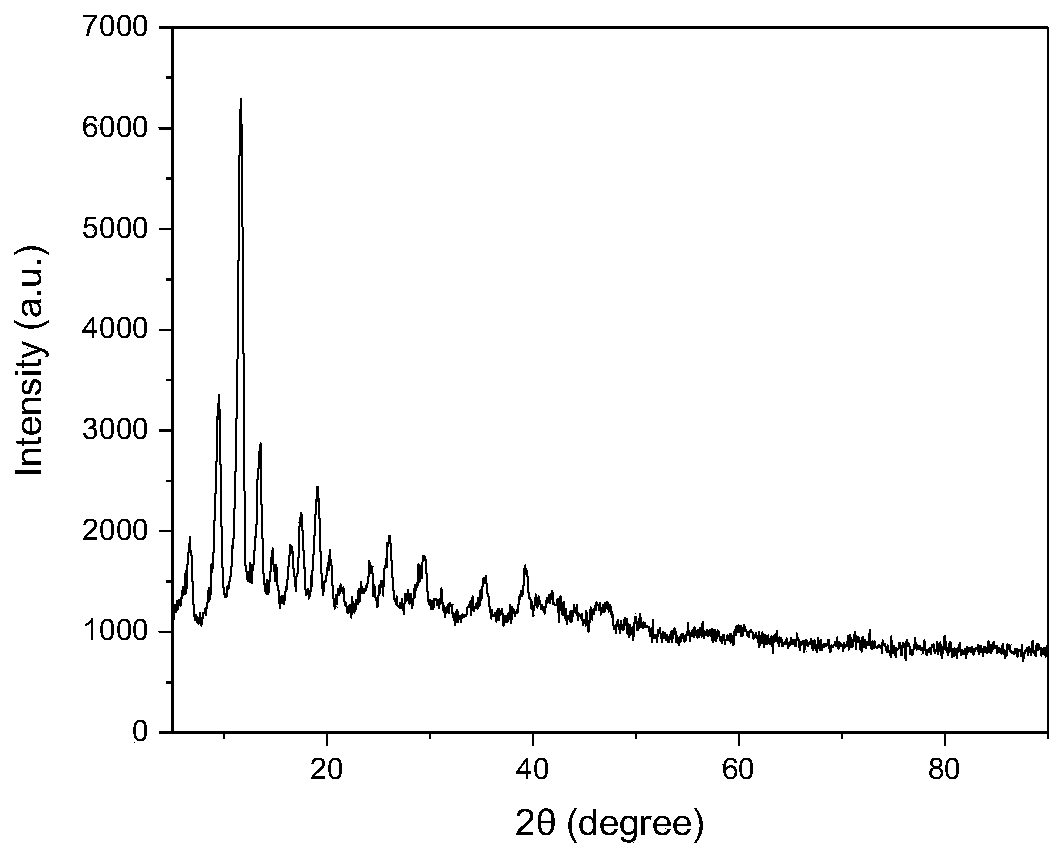

Preparation method of Cu-BTC-derived decahedron Cu<1.8>Se/C composite material

A cu1.8se and composite material technology, applied in the direction of electrochemical generators, active material electrodes, structural parts, etc., can solve the problems of small specific capacity, shortened service life, and attenuation of battery capacity of lithium-ion batteries, and achieve uniform size , High crystallinity, not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

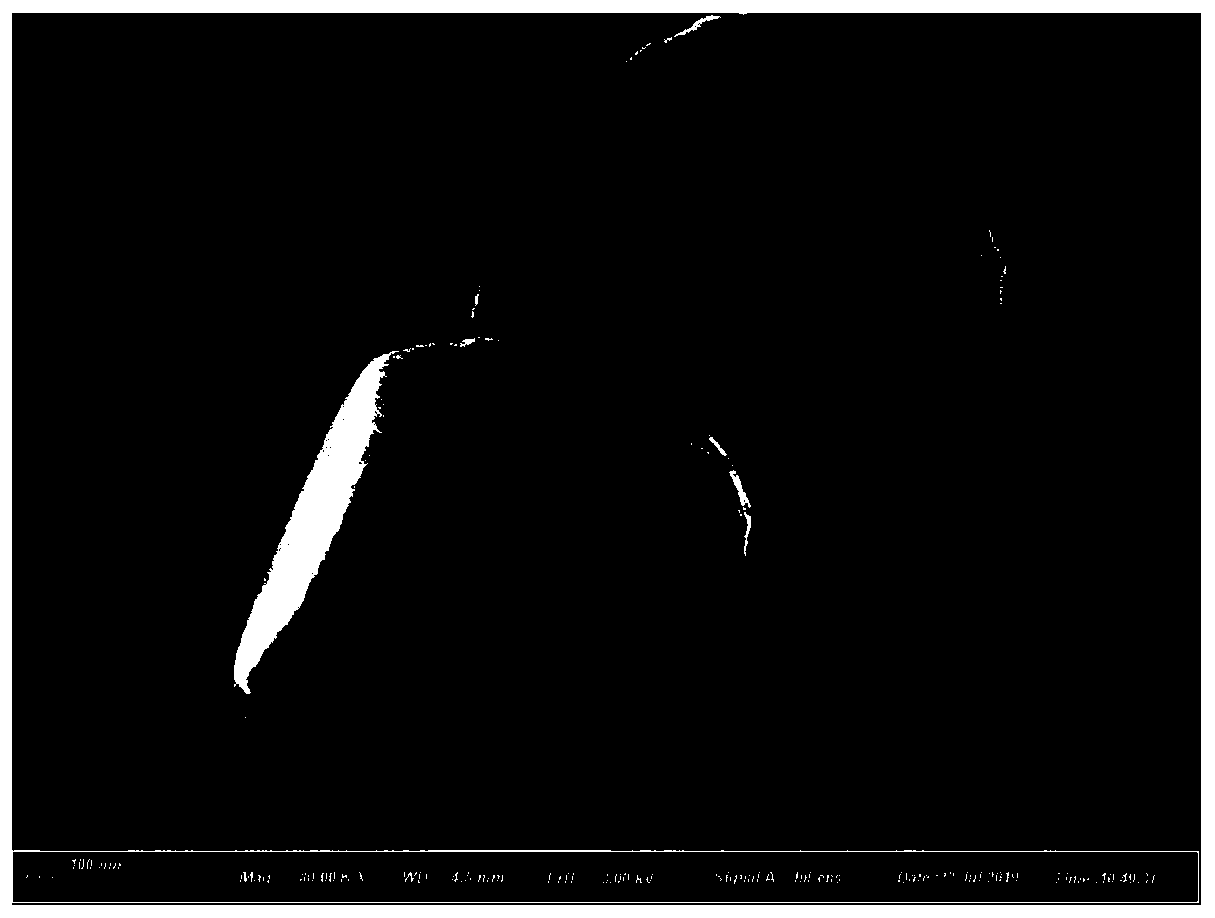

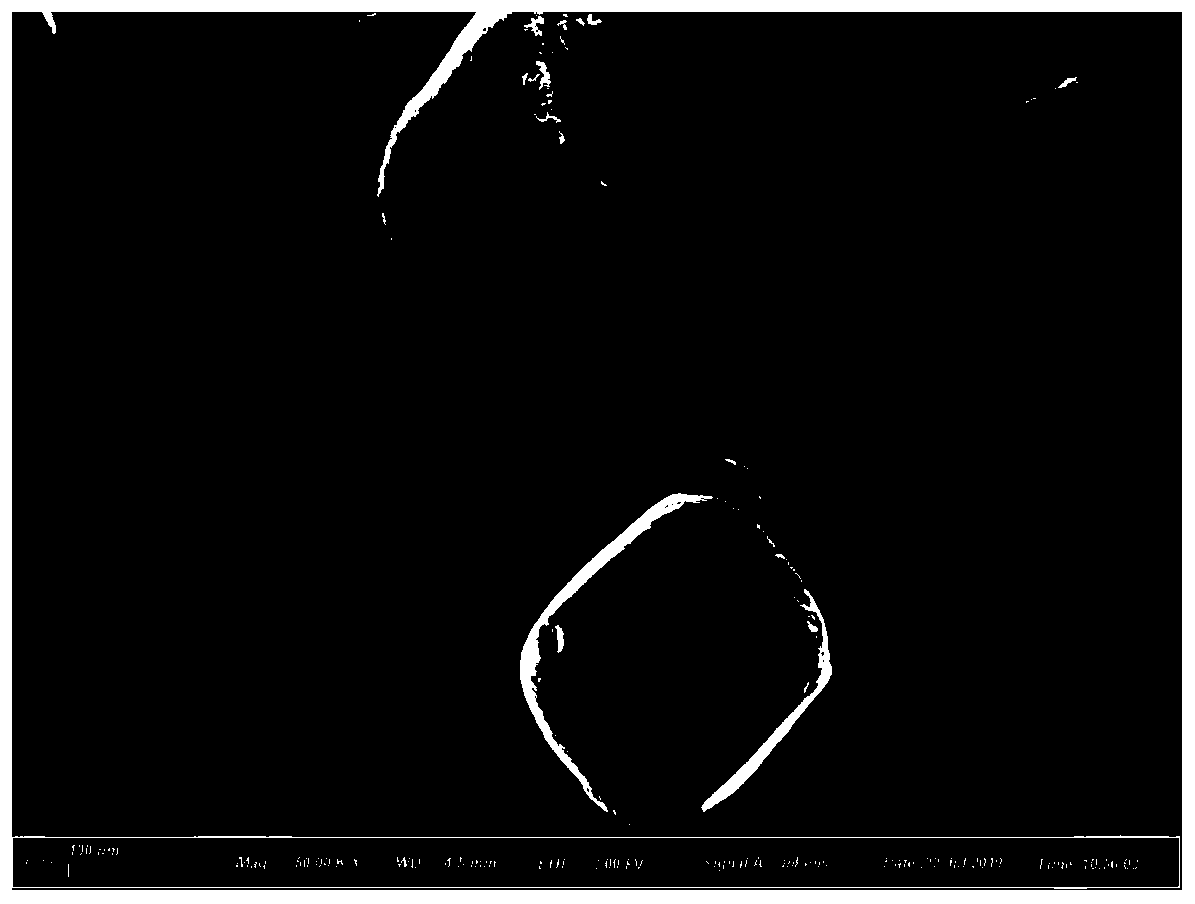

[0046] Decahedral Cu derived from a metal-organic framework Cu-BTC 1.8 The preparation method of Se / C composite material, comprises the steps:

[0047] (1) Preparation of Cu-BTC

[0048] a. Weigh 2.4g Cu(NO 3 ) 2 ·3H 2 O and 1.5g polyvinyl alcohol were dissolved in a mixed solution of methanol and ultrapure water, and magnetically stirred at a rate of 370rpm / min for 15min to form solution A, Cu(NO 3 ) 2 ·3H 2 The mass volume ratio of O to the mixed solution is 2.4:0.05 (g / L), and the volume ratio of methanol and ultrapure water in the mixed solution is 2:1;

[0049] b. According to Cu(NO 3 ) 2 ·3H 2 The molar ratio of O to 1,3,5-benzenetricarboxylic acid is 1.84:1. Weigh 1,3,5-benzenetricarboxylic acid, dissolve it in a mixed solution of methanol and ultrapure water, and perform a magnetic test at a rate of 370rpm / min. Stir for 15 minutes to form solution B, wherein the mixed solution is mixed according to the volume ratio of methanol and ultrapure water of 2:1, and ...

Embodiment 2

[0061] Decahedral Cu derived from a metal-organic framework Cu-BTC 1.8 The preparation method of Se / C composite material, comprises the steps:

[0062] (1) Preparation of Cu-BTC

[0063] a. Weigh 1.2g Cu(NO 3 ) 2 ·3H 2 O and 0.8g polyvinyl alcohol were dissolved in a mixed solution of methanol and ultrapure water, and magnetically stirred at a rate of 450rpm / min for 20min to form solution A, wherein the volume ratio of methanol and ultrapure water in the mixed solution was 2 :1, Cu(NO 3 ) 2 ·3H 2 The mass volume ratio of O to the mixed solution is 1.2:0.08 (g / L);

[0064] b. According to Cu(NO 3 ) 2 ·3H 2 The molar ratio of O to 1,3,5-benzenetricarboxylic acid is 2:1. Weigh 1,3,5-benzenetricarboxylic acid, dissolve it in a mixed solution of methanol and ultrapure water, and perform magnetic testing at a rate of 350rpm / min. Stir for 20 minutes to form solution B, wherein the mixed solution is mixed according to the volume ratio of methanol and ultrapure water of 2:1,...

Embodiment 3

[0070] A Cu-BTC derived decahedral Cu 1.8 The preparation method of Se / C composite material is characterized in that, according to the following steps:

[0071] (1) Preparation of Cu-BTC

[0072] a. Weigh 2.9gCu(NO 3 ) 2 ·3H 2 0 and 2g polyvinyl alcohol, be dissolved in the mixed solution of methanol and ultrapure water, and carry out magnetic stirring 15min according to the speed of 350rpm / min, form solution A, wherein the volume ratio of methanol and ultrapure water in mixed solution is 2: 1, Cu(NO 3 ) 2 ·3H 2 The mass volume ratio of O to the mixed solution is 2.9:0.04 (g / L);

[0073] b. According to Cu(NO 3 ) 2 ·3H 2 The molar ratio of O to 1,3,5-benzenetricarboxylic acid is 1:1. Weigh 1,3,5-benzenetricarboxylic acid, dissolve it in the mixed solution of methanol and ultrapure water, and perform magnetic Stir for 20 minutes to form solution B, wherein the mixed solution is mixed according to the volume ratio of methanol and ultrapure water of 2:1, and the mass v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com