Cu-SSY-39 molecular sieve, and preparation method and application thereof

A cu-ssz-39, molecular sieve technology, applied in the direction of molecular sieves and base exchange compounds, separation methods, chemical instruments and methods, etc., can solve the problems of complicated process, high time, high economic cost, economic and environmental benefits, etc. , to achieve the effects of simplified preparation method, excellent nitrogen selectivity, and wide temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The nitrogen-containing organic template used in this example is N,N-diethyl-2,6-dimethylpiperidine, and its preparation method includes the following steps:

[0087] (a) Mix 35g of cis-2,6-dimethylpiperidine, 180g of iodoethane, 70g of potassium bicarbonate and 120g of methanol, and carry out stirring and reflux reaction at 50°C for 4 days;

[0088] (b) Rotating the product of the reflux reaction of step (a) to remove the liquid, then adding chloroform for dissolution, and suction filtering to remove the solid to obtain a mixed solution;

[0089] (c) Rotate the mixed solution obtained in step (b) to remove chloroform, then add ethanol and ether for recrystallization to obtain N,N-diethyl-cis-2,6-dimethylpiperidinium iodide powder ;

[0090] (d) dissolving the recrystallized product of step (c) in water and performing ion exchange with a hydroxide type cation resin to obtain the nitrogen-containing organic template, which is N,N-diethyl- 2,6-Dimethylpiperidine.

[00...

Embodiment 2

[0101] The difference between this example and Example 1 is that the raw materials in step (a) are replaced by 40g cis-2,6-dimethylpiperidine, 200g ethyl iodide, 80g potassium bicarbonate and 150g methanol, other conditions and implementation Exactly the same as compared to Example 1.

[0102] The mass percent content of Cu element in the Cu-SSZ-39 molecular sieve obtained in this example is 2.1%.

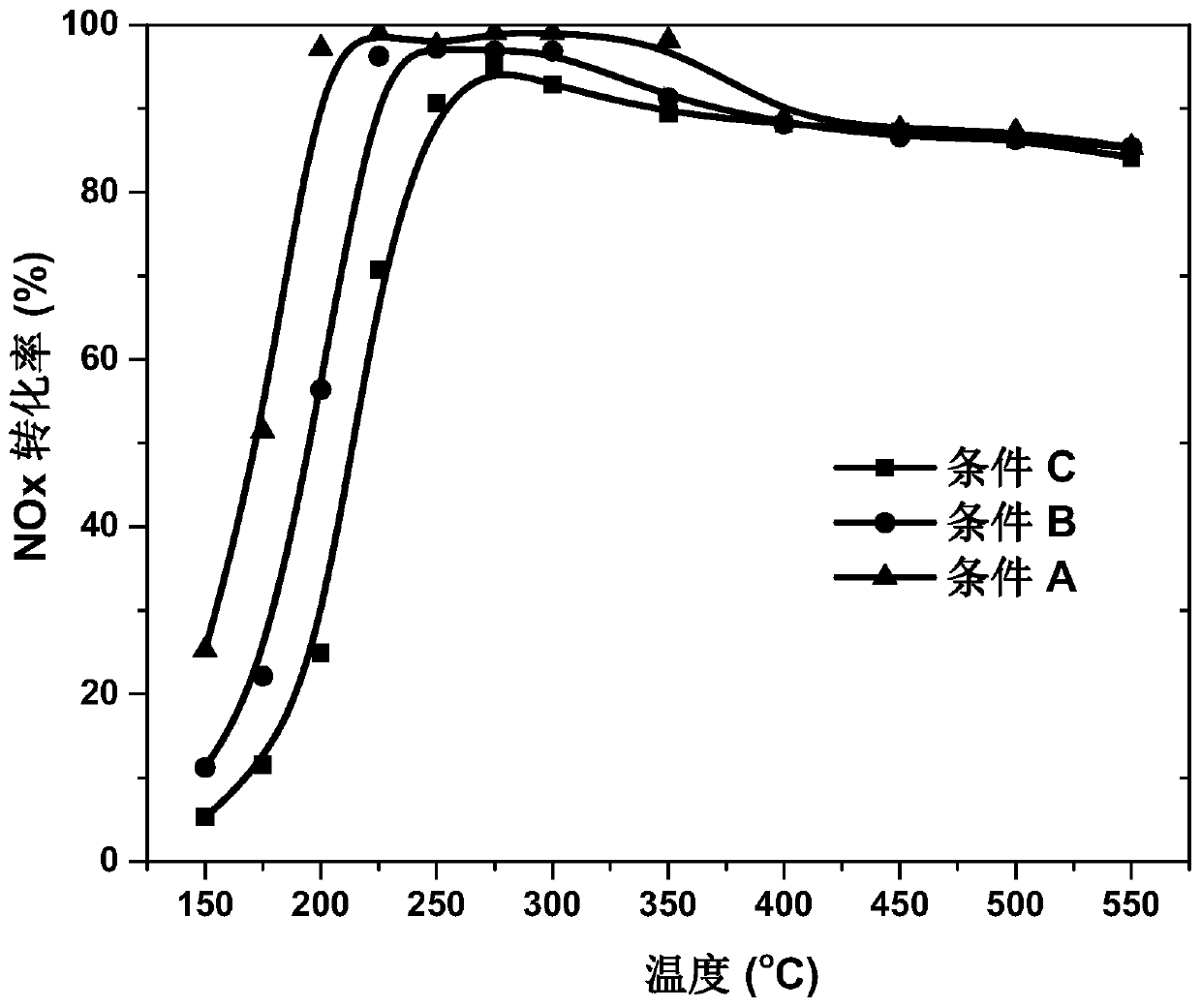

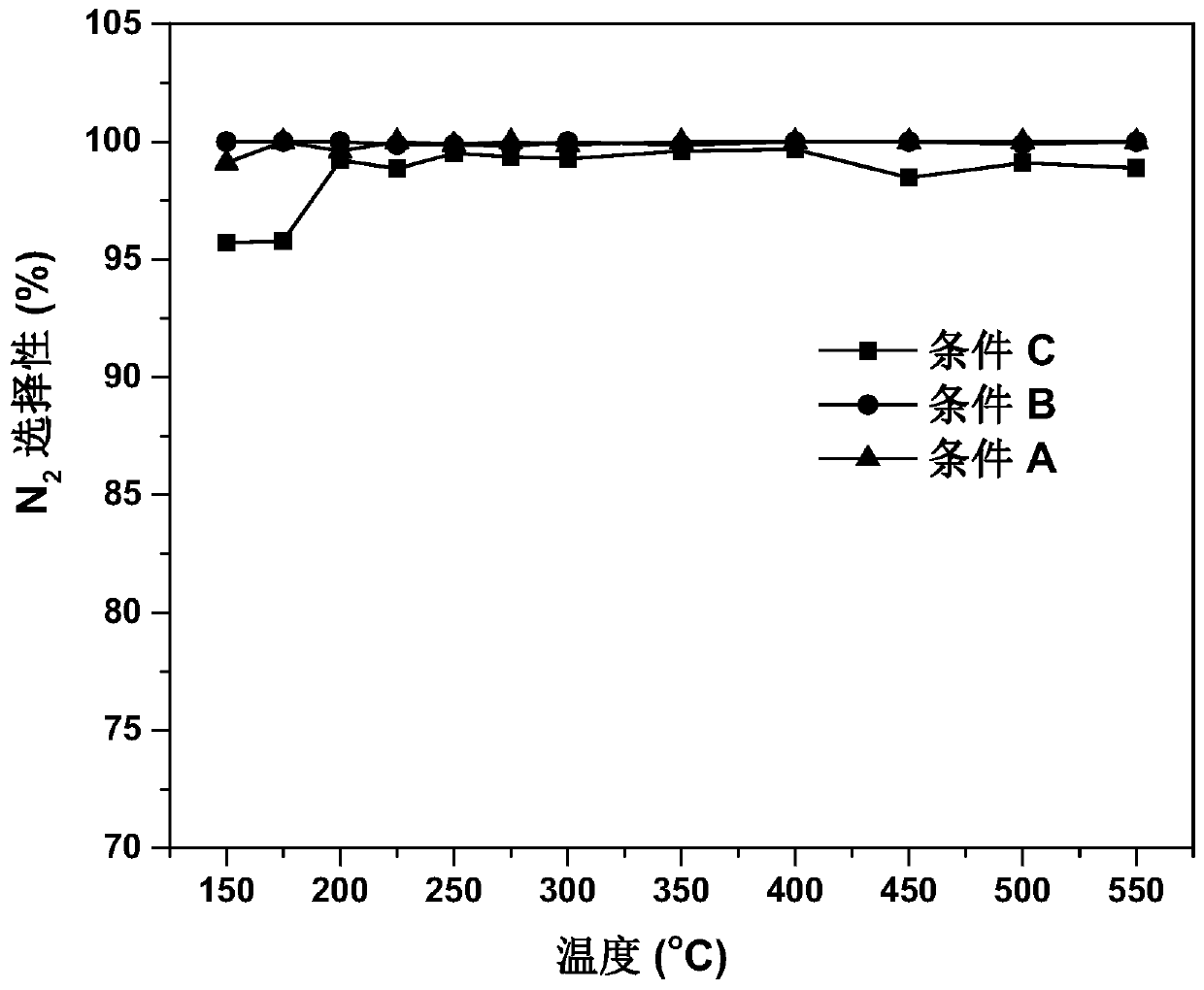

[0103] Cu-SSZ-39 molecular sieve was prepared in this example, and under the test conditions of the present invention, the removal rate of nitrogen oxides in the temperature range of 250°C-500°C was maintained above 75%, and the nitrogen selectivity was 150%. ℃-550 ℃ temperature range are maintained at more than 95%. It can be seen that the Cu-SSZ-39 molecular sieve catalyst synthesized in this example has excellent NH 3 - SCR activity and nitrogen selectivity.

Embodiment 3

[0105] The difference between this example and Example 1 is that in step (a), the mass of cis-2,6-dimethylpiperidine is replaced by cis-3,5-dimethylpiperidine, and the ZSM-5 The silicon-aluminum ratio of the molecular sieve is 12, and other conditions are exactly the same as those in Example 1.

[0106] The mass percent content of Cu element in the Cu-SSZ-39 molecular sieve obtained in this example is 2.1%.

[0107] This example prepares Cu-SSZ-39 molecular sieve, under the test conditions of the present invention, its removal rate of nitrogen oxides in the temperature range of 250°C-550°C is maintained above 80%, and the nitrogen selectivity is between The temperature range of 150°C-550°C is maintained above 95%. It can be seen that the Cu-SSZ-39 molecular sieve catalyst synthesized by this example has excellent NH 3 - SCR activity and nitrogen selectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com