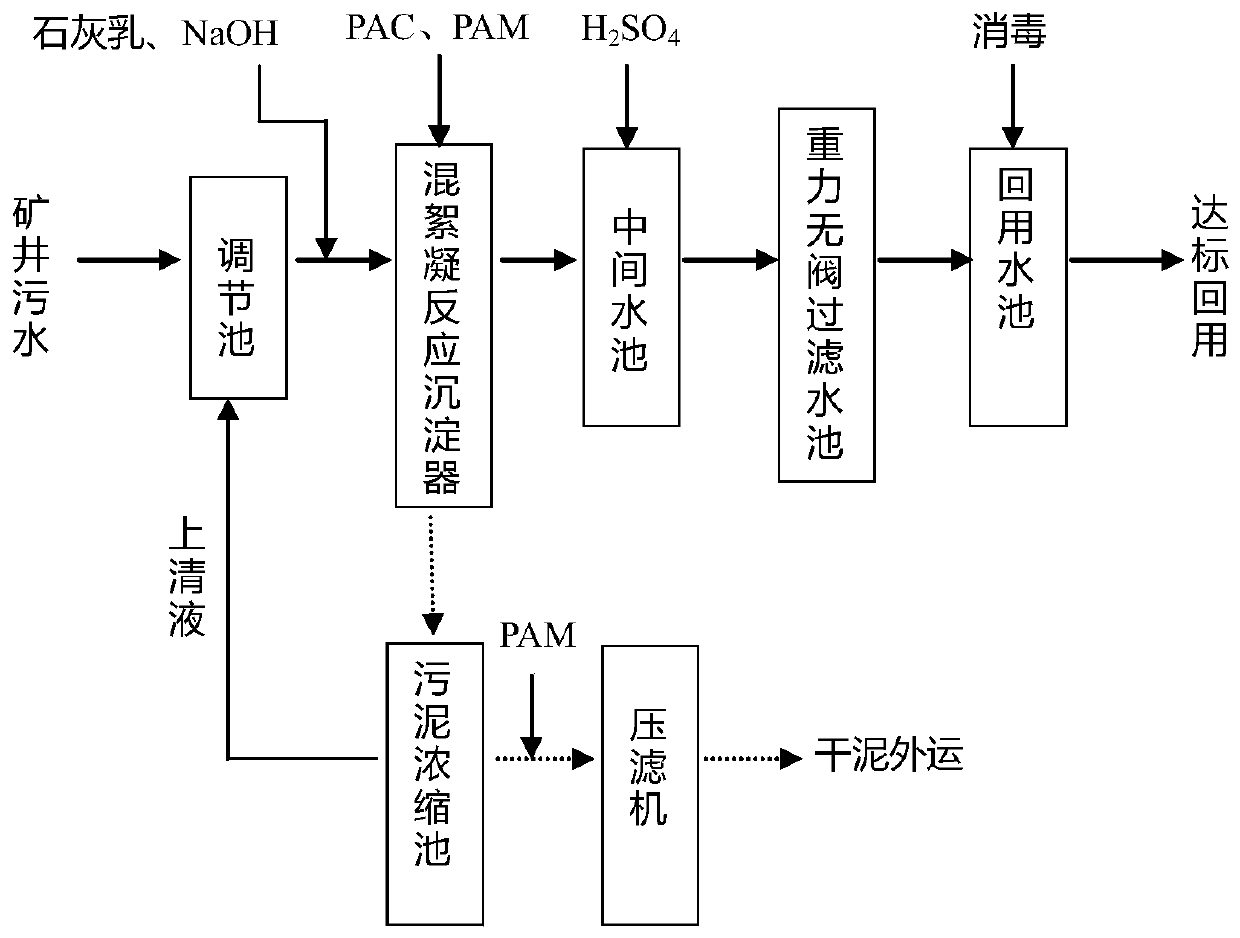

Mine shaft sewage treatment process

A treatment process and sewage technology, applied in the field of mine sewage treatment process, can solve the problems of small particle size of suspended solids, poor sensory properties, slow settling speed, etc., and achieve good coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The mine water treatment project produced during the production of a mine in Shanxi, the influent water quality is as follows: pH value 7~9, COD150mg / L, SS 1500mg / L, sulfate 837mg / L, phosphate 1.89mg / L, iron ion 1.73mg / L L, total hardness 760mg / L. The total hardness of the mine sewage is relatively high, the suspended matter is too high, and the ferric ion, sulfate and phosphate all exceed the standard, which belongs to the sewage with serious pollution.

[0019] In view of the problem of sulfate treatment in this project, our company researched and pre-selected coagulation sedimentation method to remove sulfate, hardness and SS. Specific steps are as follows:

[0020] (1) Mine sewage enters the regulating pool for water volume and water quality regulation;

[0021] (2) The adjusted mine sewage is lifted by the lift pump into the coagulation reaction precipitator, adding sodium hydroxide to adjust the pH of the mine sewage to 10-10.5, then adding lime milk and using l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com