Aluminum nitride/aluminum oxide composite ceramic and preparation method thereof

A technology of alumina ceramics and multiphase ceramics, which is used in ceramic molding machines, manufacturing tools, additive processing, etc. problems, to achieve the effects of excellent thermal conductivity and dense performance, good dispersion uniformity, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

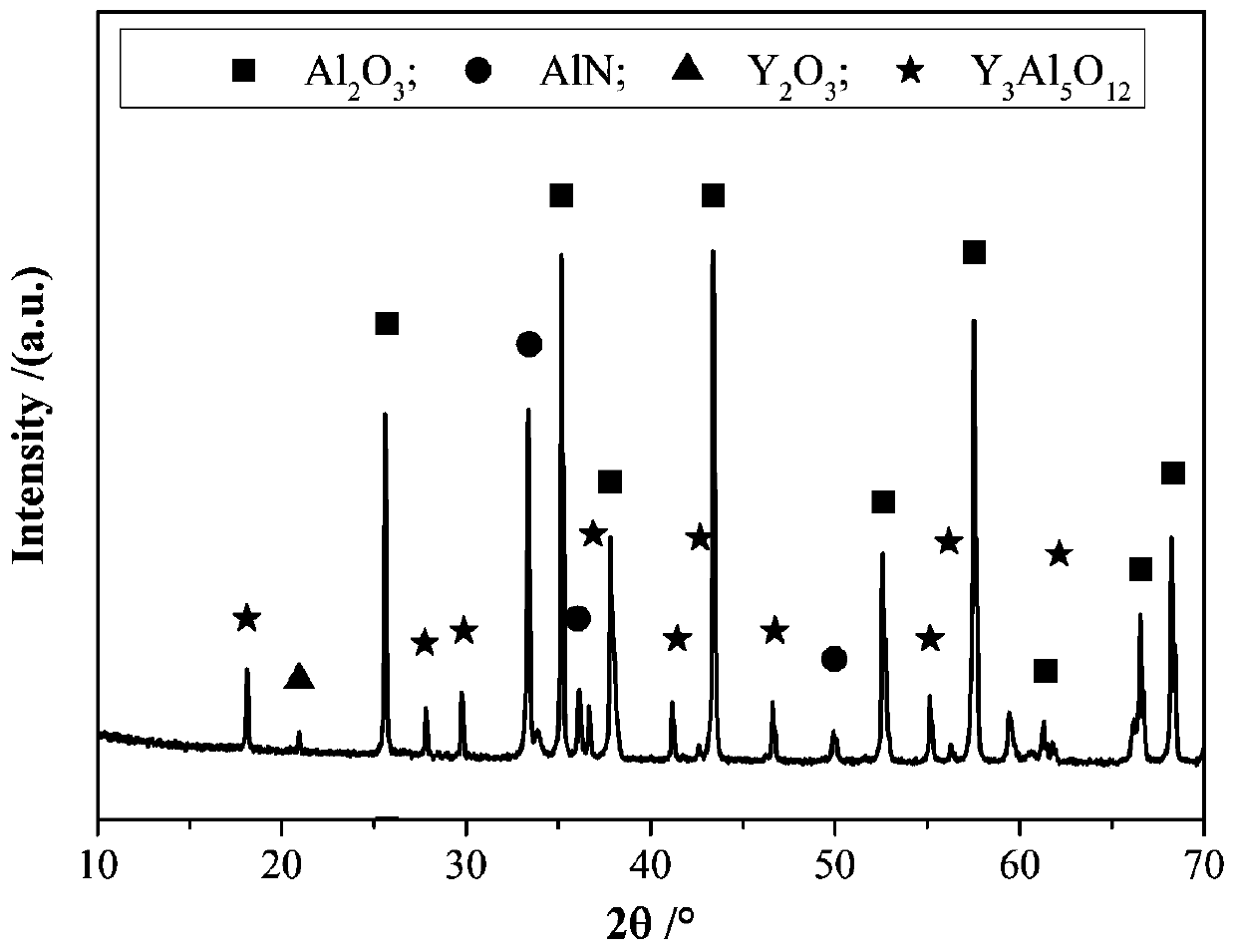

Image

Examples

Embodiment 1

[0047] This embodiment provides the first preparation method of aluminum nitride / alumina composite ceramics, the specific steps are as follows:

[0048] 1. Weigh 71 parts by weight of alumina ceramic powder, 1.42 parts by weight of yttrium oxide, 20.58 parts by weight of hexanediol diacrylate, 7 parts by weight of FQ-9 phenolic resin and 1.06 parts by weight of BYK 9076 dispersant, and ball mill for 10 hours Finally, 0.02 part of Darocur 1173 photoinitiator was added, and ball milling was continued for 5 minutes to obtain an alumina ceramic slurry with a solid content of 40 vol%.

[0049] 2. Use a light-curing 3D printer to carry out light-curing 3D printing and molding, control the laser wavelength to 250nm, and the exposure to 100mJ / cm 2 , the single-layer curing time is 1s, and the printing layer thickness is 50μm; 3D printing is carried out according to the preset three-dimensional structure model, and a special-shaped alumina ceramic green body is obtained.

[0050] 3. P...

Embodiment 2

[0054] This embodiment provides the second preparation method of aluminum nitride / alumina composite ceramics, the specific steps are as follows:

[0055] 1. Weigh 75 parts by weight of alumina ceramic powder, 3.75 parts by weight of yttrium fluoride, 14.75 parts by weight of polyurethane acrylate, 5 parts by weight of n-butyl acrylate, 1.5 parts by weight of 2130 phenolic resin and 1.5 parts by weight of SOLSPERSE 8000 dispersant, After 24 hours of ball milling, 0.59 parts of Irgacure 184 photoinitiator was added, and ball milling was continued for 10 minutes to obtain an alumina ceramic slurry with a solid content of 47 vol%.

[0056] 2. Use a light-curing 3D printer for light-curing 3D printing, control the laser wavelength to 460nm, and the exposure to 4mJ / cm 2 , the single-layer curing time is 15s, and the printing layer thickness is 10μm; 3D printing is carried out according to the preset three-dimensional structure model, and a special-shaped alumina ceramic green body i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity at room temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com