Polyphenylene sulfide preparation method

A polyphenylene sulfide and sodium sulfide technology, applied in the field of polyphenylene sulfide preparation, can solve the problems of single raw material selection and restriction of polyphenylene sulfide preparation process, etc., and achieve universal production process, easy acquisition, and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

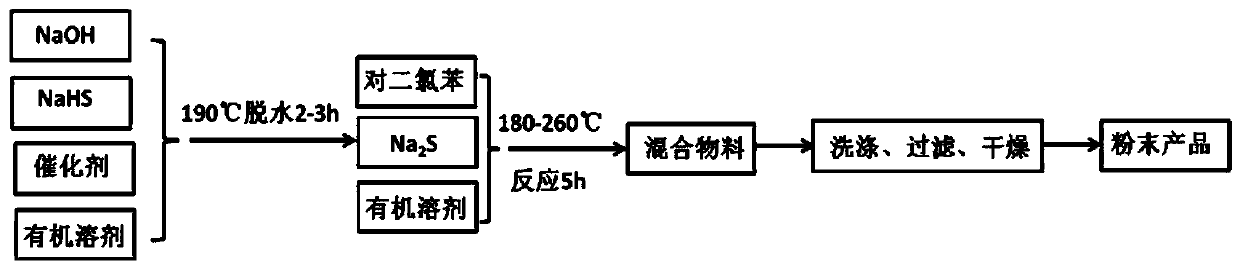

[0024] The invention provides a kind of preparation method of polyphenylene sulfide, comprises the following steps:

[0025] Sodium hydroxide and sodium hydrosulfide are dehydrated to obtain a mixed solution containing sodium sulfide;

[0026] The mixed solution containing sodium sulfide is mixed with p-dichlorobenzene to carry out polymerization reaction to obtain polyphenylene sulfide.

[0027] In the present invention, unless otherwise specified, all raw materials are commercially available products well known in the art.

[0028] In the invention, sodium hydroxide and sodium hydrosulfide are subjected to dehydration reaction to obtain a mixed liquid containing sodium sulfide.

[0029] In the present invention, the mass ratio of the sodium hydroxide and sodium hydrosulfide is preferably (3.0~3.4):(9.8~10.2), more preferably 3.2:10; The form participates in the dehydration reaction, and the mass concentration of the sodium hydrosulfide solution is preferably 45%. In the p...

Embodiment 1

[0040] according to figure 1 The flow process shown, in the three-neck flask equipped with condenser tube, stirrer, thermometer, add N-methylpyrrolidone 40g, mass fraction is 45% sodium hydrosulfide solution 12.445g, sodium hydroxide 4g, lithium chloride 2.1 g, start stirring and feed nitrogen (flow rate 200-300mL / min), heat up to 180-190°C and react for 2-3 hours, the dehydration rate can reach 80%-90%, and a tail gas absorption system is installed at the end of the device . After the dehydration reaction, when the temperature dropped to 100°C, 14.7 g of p-dichlorobenzene and 10 g of N-methylpyrrolidone were added to the three-necked flask, and the temperature was rapidly raised to 190°C for 5 hours. After the polymerization reaction is over, stop stirring, pour the mixed material into hot deionized water at 85°C while it is hot, and place it in a constant temperature tank for heating for 30 minutes, repeat dissolving, washing, and filtering for 6 times, and place it in a ho...

Embodiment 2

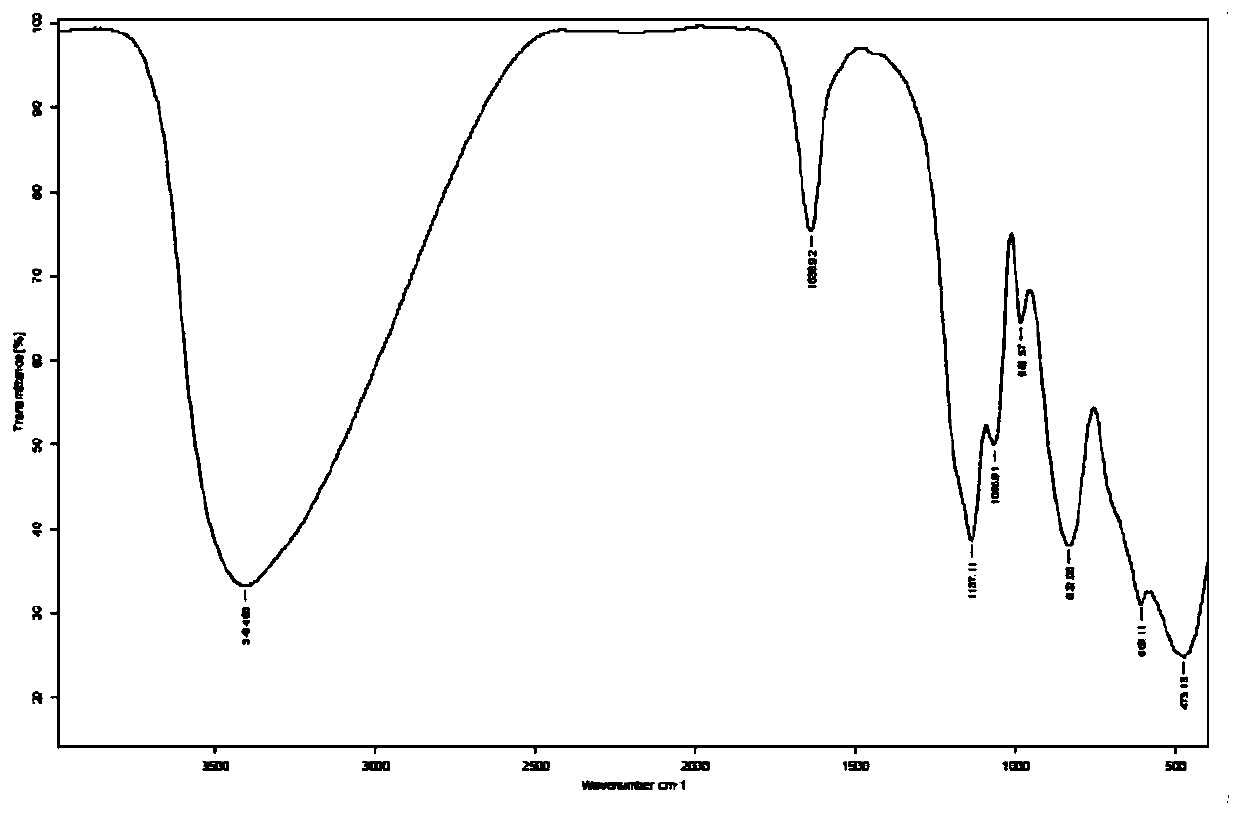

[0043] According to the method and steps of Example 1, the difference is that in Example 2: the temperature of the polymerization reaction is 200° C. for 5 hours. Infrared analysis was carried out on the product of Example 2, showing that the product was a PPS polymer; the number average molecular weight of the obtained polymer was 35156, and the yield was 44.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com