Method of preparing PDLC liquid crystal dimming film containing nano silver wire transparent conductive film

A technology of liquid crystal dimming film and transparent conductive film, which is applied in the field of preparation of PDLC liquid crystal dimming film, and can solve the problems of high cost, complicated manufacturing process, and large equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

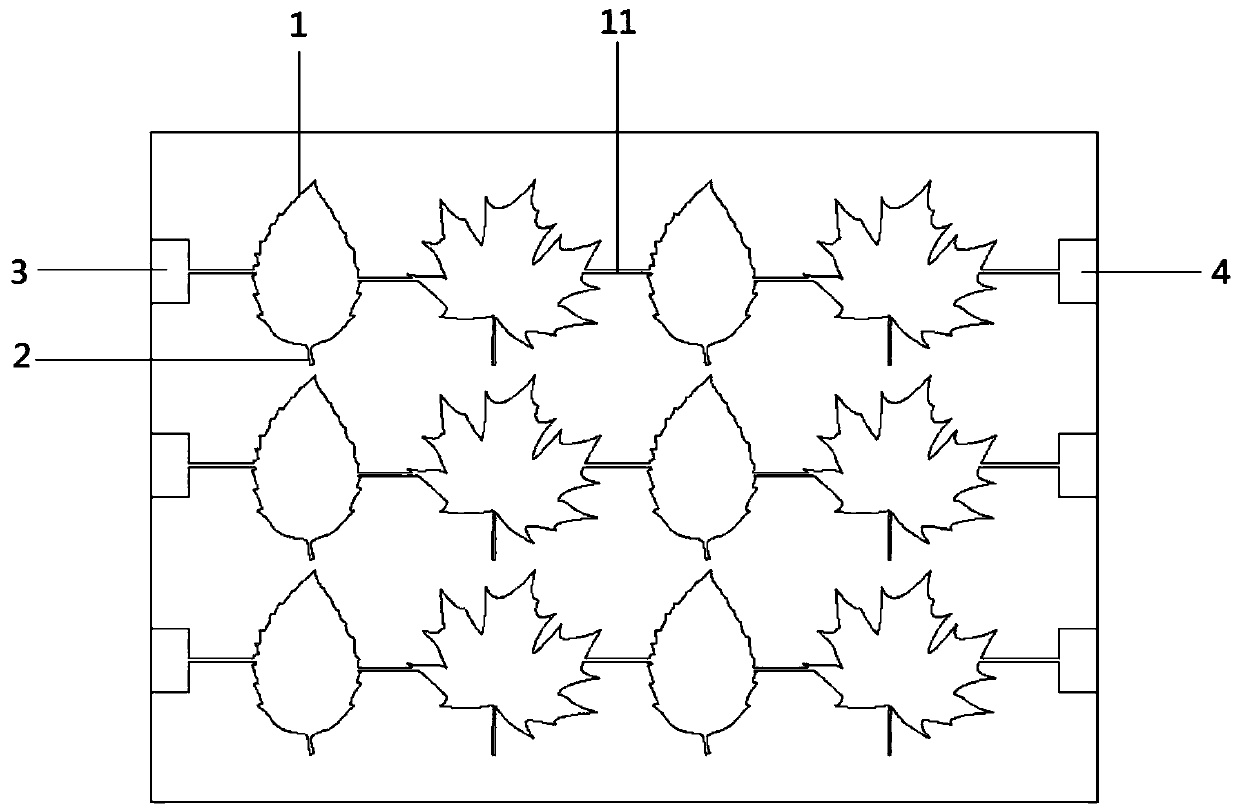

[0091] like figure 1 As shown, in this embodiment 1, there are three rows of patterns from top to bottom etched on the PDLC liquid crystal dimming film containing nano-silver wire transparent conductive film, and each row of patterns consists of two ordinary leaf patterns and two maple leaf patterns A total of four patterns are composed alternately.

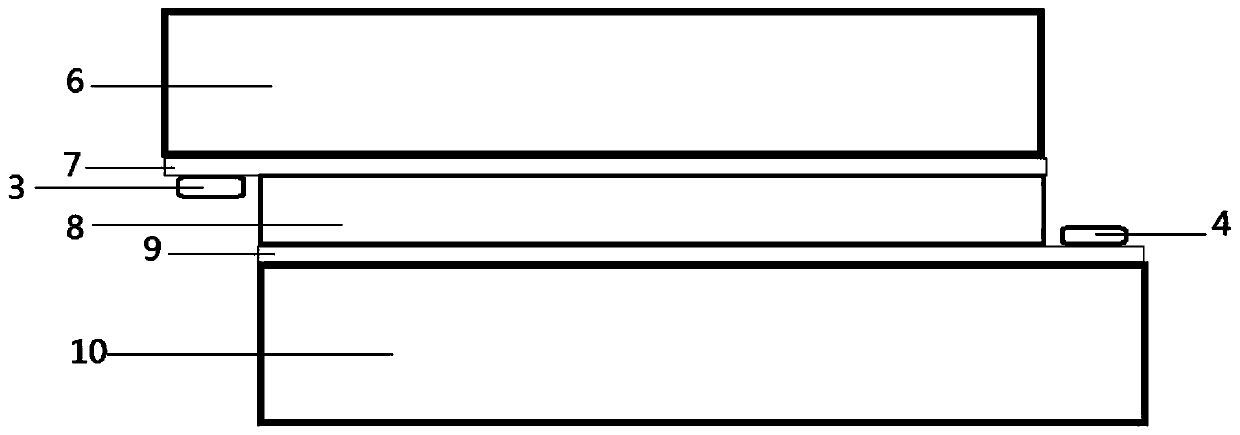

[0092] Taking the top row of patterns as an example, the pattern is composed of etching line A1 and etching line B2, and electrode A3 and electrode B4 are respectively arranged on the left and right sides of the PDLC liquid crystal dimming film; at the same time, in In this embodiment 1, the electrode A3 on the left side of the PDLC liquid crystal dimming film is jointly arranged on the first nano silver wire layer 7, and the electrode B4 on the right side of the PDLC liquid crystal dimming film is jointly arranged on the second nanometer silver wire layer 7. Silver wire on layer 9.

[0093] In this embodiment, the thickness of...

Embodiment 2

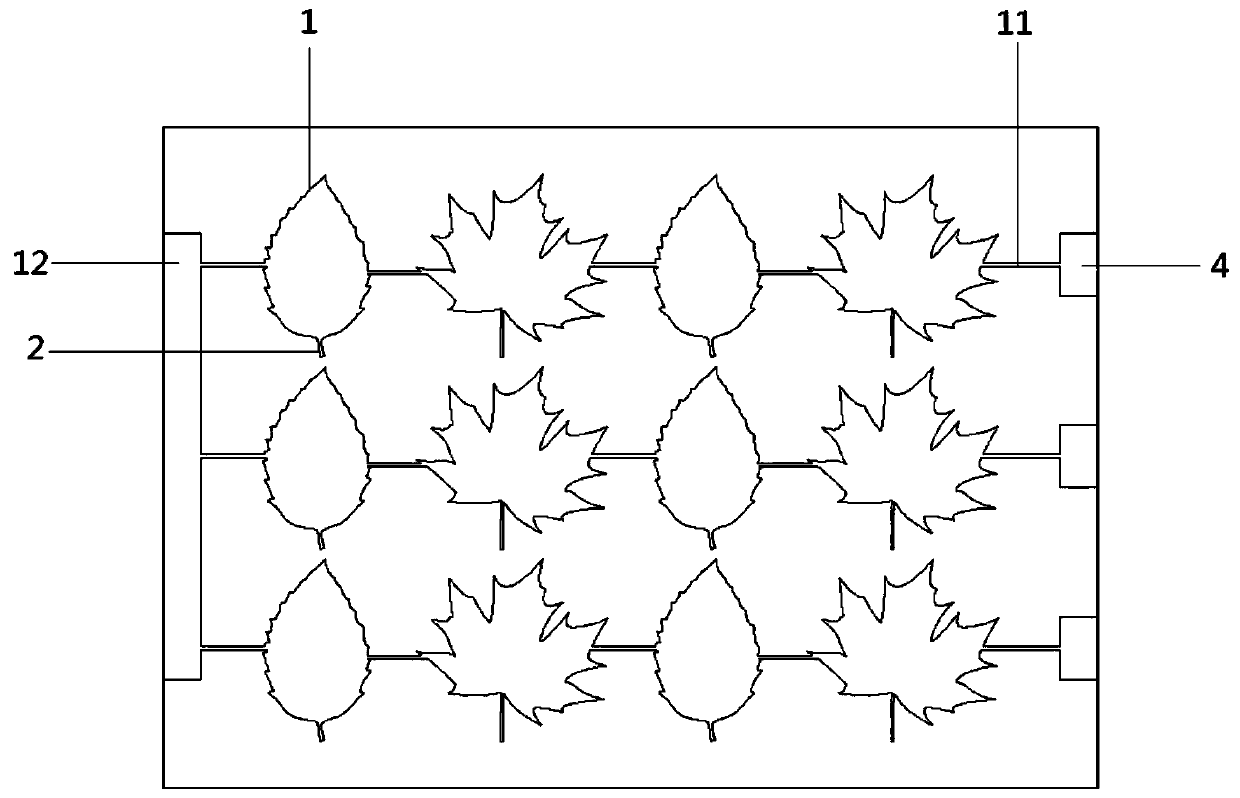

[0124] image 3 Another specific embodiment 2 of the technical solution disclosed in the present invention is shown; wherein, the three electrodes on the left are prepared as a common electrode 12 . In Example 2, except for the conditions and data described below, the same materials, steps and parameters as in Example 1 were used.

[0125] In the present embodiment 2, the hardening treatment in the first step is a slot extrusion coating, and the PET film base is double-coated with a hardening solution for hardening treatment. Among them, in terms of weight percentage, the components of the hardening solution are: 7% pure acrylic resin, 18% ten-functional polyurethane resin, 26% difunctional polyurethane resin, 10% reactive diluent, 4% photoinitiator and 35% solvent acetone .

[0126] The reactive diluent is tripropylene glycol diacrylate.

[0127] The photoinitiator is phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide.

[0128] Hot pressing at a temperature of 200°C and a p...

Embodiment 3

[0134] Figure 4 Embodiment 3 in the technical solution of the present invention is shown. In this embodiment, the thickness of the PDLC liquid crystal dimming film, the PET1 layer 6 or the PET2 layer 10 is 300 μm; the first nano silver wire layer 7 or the second nano silver wire layer The thickness of the wire layer 9 is 80nm; the thickness of the PDLC layer 8 is 120 μm; the width of the nano-silver wire layer connecting region 11 is 80 μm; the width of the etched line is 60 μm.

[0135] like Figure 4 As shown, three rows of patterns are etched on the PDLC liquid crystal dimming film, and each row is composed of three letter patterns, which are the three letter patterns of English letters B, M and W. The difference from Example 1 is that each letter is composed of two separate etching lines. After two etchings, the etching line A1 and the etching line B2 are etched respectively, forming a first nanometer The independent partitions of the silver wire layer and the independe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com