Topical pharmaceutical composition containing water-insoluble analgesic and preparation method and application thereof

A water-insoluble, composition-based technology, applied in the field of pharmacy, can solve the problems of easy decomposition of ozone, limited application, and low solubility, and achieve the effects of easy portability, enhanced analgesic effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

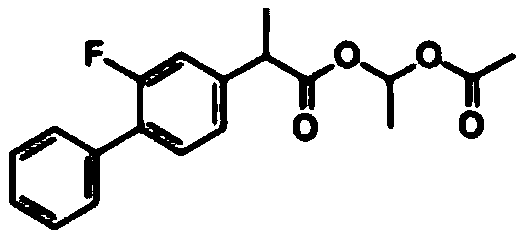

Embodiment example 1

[0048] Implementation case 1 prepares the prescription as follows (the specification of flurbiprofen axetil is 10mg / 100g, and the ointment is calculated in 100g):

[0049]

[0050]

[0051] Preparation Process:

[0052] (1) Dissolve flurbiprofen axetil, PLGA-PEG-NHS and olive oil in the organic solvent ethyl acetate under stirring to obtain the oil phase, and pass through the prescription amount of ozone, and heat in a water bath at 40-50°C 30~60min;

[0053] (2) By adding buffer solution (NaH 2 PO 4 ---Na 2 HPO 4 ) controlling the pH of the aqueous phase containing a certain proportion of egg yolk lecithin at 6.7 to 7.7;

[0054] (3) Adding the oil phase to the water phase under stirring conditions, using a high-speed shearing instrument to prepare an emulsion, and controlling its particle size below 120nm;

[0055] (4) Under stirring, the emulsion is then fed into the ultrafine particle preparation system (UPPS) at a constant speed by a peristaltic pump under sti...

Embodiment example 2

[0059] Prepare the prescription as follows (the specification of propofol is 100mg / 100g, and the ointment is calculated as 100g):

[0060]

[0061] Preparation Process:

[0062] (1) Dissolve propofol, mPEG2000-b-PLGA1000 and camellia oil in the organic solvent ethyl acetate under stirring to obtain the oil phase, and inject the prescribed amount of ozone, and heat in a water bath at 40-50°C for 30- 60min;

[0063] (2), by adding buffer solution (NaH 2 PO 4 ---Na 2 HPO 4 ) controlling the pH of the aqueous phase containing a certain proportion of egg yolk lecithin at 6.7 to 7.7;

[0064] (3) The oil phase is added to the water phase under stirring conditions, and an emulsion is prepared by using a cell disruptor, and the particle size is controlled below 120nm;

[0065] (4) Under stirring, the emulsion is fed into the ultrafine particle preparation system (UPPS) at a constant speed by a peristaltic pump, and ethyl acetate is removed under negative pressure vacuum condi...

Embodiment example 3

[0069] Prepare the prescription as follows (the specification of flurbiprofen axetil is 20mg / 100g, and the ointment is calculated in 100g):

[0070]

[0071] Preparation Process:

[0072] (1) Dissolve flurbiprofen axetil, mPEG-PLGA-NHS, and soybean oil in the organic solvent ethyl acetate under stirring to obtain the oil phase, and pass through the prescribed amount of ozone, and heat in a water bath at 40-50°C 30~60min;

[0073] (2) By adding buffer solution (NaH 2 PO 4 ---Na 2 HPO 4 ) controlling the pH of the aqueous phase containing a certain proportion of poloxamer at 6.7 to 7.7;

[0074] (3) Add the oil phase to the water phase under stirring conditions, and prepare an emulsion by using a high-speed shearing instrument, and control its particle size below 120nm;

[0075] (4) Under stirring, the emulsion is then fed into the ultrafine particle preparation system (UPPS) at a constant speed by a peristaltic pump under stirring, and ethyl acetate is removed under ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com