Preparation method of titanium-iron-nickel electrocatalyst with high hydrogen evolution activity

A technology of electrocatalysts and electrocatalytic materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as waste of energy, poor stability and no use value , to achieve the effects of reducing overpotential, improving electrolysis efficiency, and firm thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

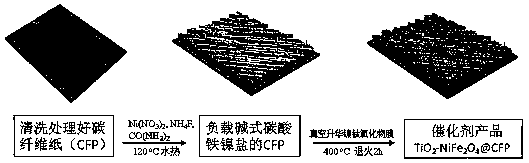

[0027] The preparation process of the sample of the embodiment of the present invention is as follows figure 1 shown.

[0028] Cleaned and processed carbon fiber paper, in Ni (NO 3 ) 2 , (NH 4 ) 2 Fe(SO 4 ) 2 , NH 4 F, CO (NH 2 ) 2 React in an aqueous solution of 120 °C in a temperature of 120 °C to obtain a CFD loaded with basic iron carbonate nickel salt precursor; place it in a vacuum coating machine, vacuum sublimation to coat a titanium oxide film, and anneal at a temperature of 300 to 500 °C for 2 hours to obtain a composite electrocatalyst product. TiO 2 -NiFe 2 O 4 @CFP-X.

Embodiment 1

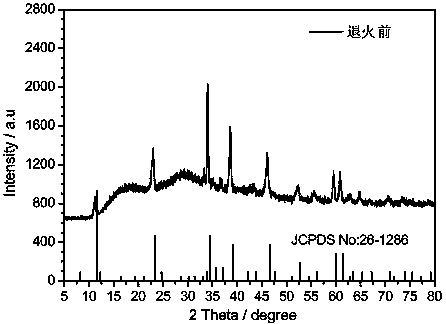

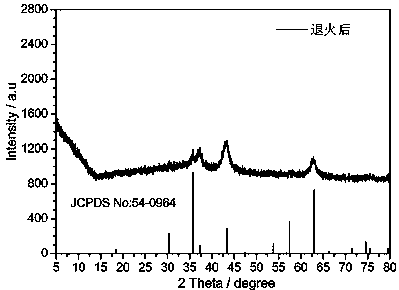

[0030] The raw material used is Ni(NO 3 ) 2 , (NH 4 ) 2 Fe(SO 4 ) 2 , NH 4 F, CO (NH 2 ) 2 , weighed in a molar ratio of 3:1:8:20, the weight of the total substance was 1.3 g, mixed and dissolved in 40 ml of water; then take a piece of carbon fiber paper (CFP) and cut it into an area of 2×3cm 2 After ultrasonic cleaning for 15min in acetone, ethanol and water respectively, take out and dry and weigh; then pour the above solution into the inner tank of the 50mL reaction kettle and add a piece of washed 2×3cm 2 CFP, sealed the reaction kettle and kept the temperature at 120 °C for 10 hours, cooled, taken out, washed and dried, and weighed the quality of the precursor loaded on the carbon fiber paper; finally, the sample was annealed in a muffle furnace at 400 degrees in an air atmosphere for 2 hours, after cooling, the TiO of Example 1 was obtained 2 -NiFe 2 O 4 The @CFP-0 composite electrocatalytic material was weighed to measure the loading.

Embodiment 2

[0032] The raw material used is Ni(NO 3 ) 2 , (NH 4 ) 2Fe(SO 4 ) 2 , NH 4 F, CO (NH 2 ) 2 , weighed in a molar ratio of 3:1:8:20, the total mass of the weighed substance was 1.3 g, mixed and dissolved in 40 ml of water; then take a piece with an area of 2 × 3 cm 2 The cleaned carbon fiber paper (CFP); then pour the above solution into the liner of the 50mL reaction kettle and add CFP, seal the reaction kettle and keep the temperature at 120 ° C for 10 hours, cool and take out, clean and dry, weigh the load on the carbon fiber The quality of the precursor on the paper; the CFD loaded with the basic iron-nickel carbonate precursor is placed in a vacuum coating machine, the coating time and speed are set, and a titanium oxide film with a thickness of 0.5 nm is plated on the surface of the iron-nickel precursor. The sample was then annealed in a muffle furnace at 400 °C for 2 hours in an air atmosphere, and the TiO of Example 2 was obtained after cooling. 2 -NiFe 2 O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com