Method for recycling sintered neodymium-iron-boron waste

A NdFeB recycling technology, applied in chemical instruments and methods, grain processing, transportation and packaging, etc., can solve the problems of inability to increase the proportion of waste recycling, product sample oxidation, low oxygen content and other problems, and reduce inventory costs , Improve the recycling rate, improve the effect of recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

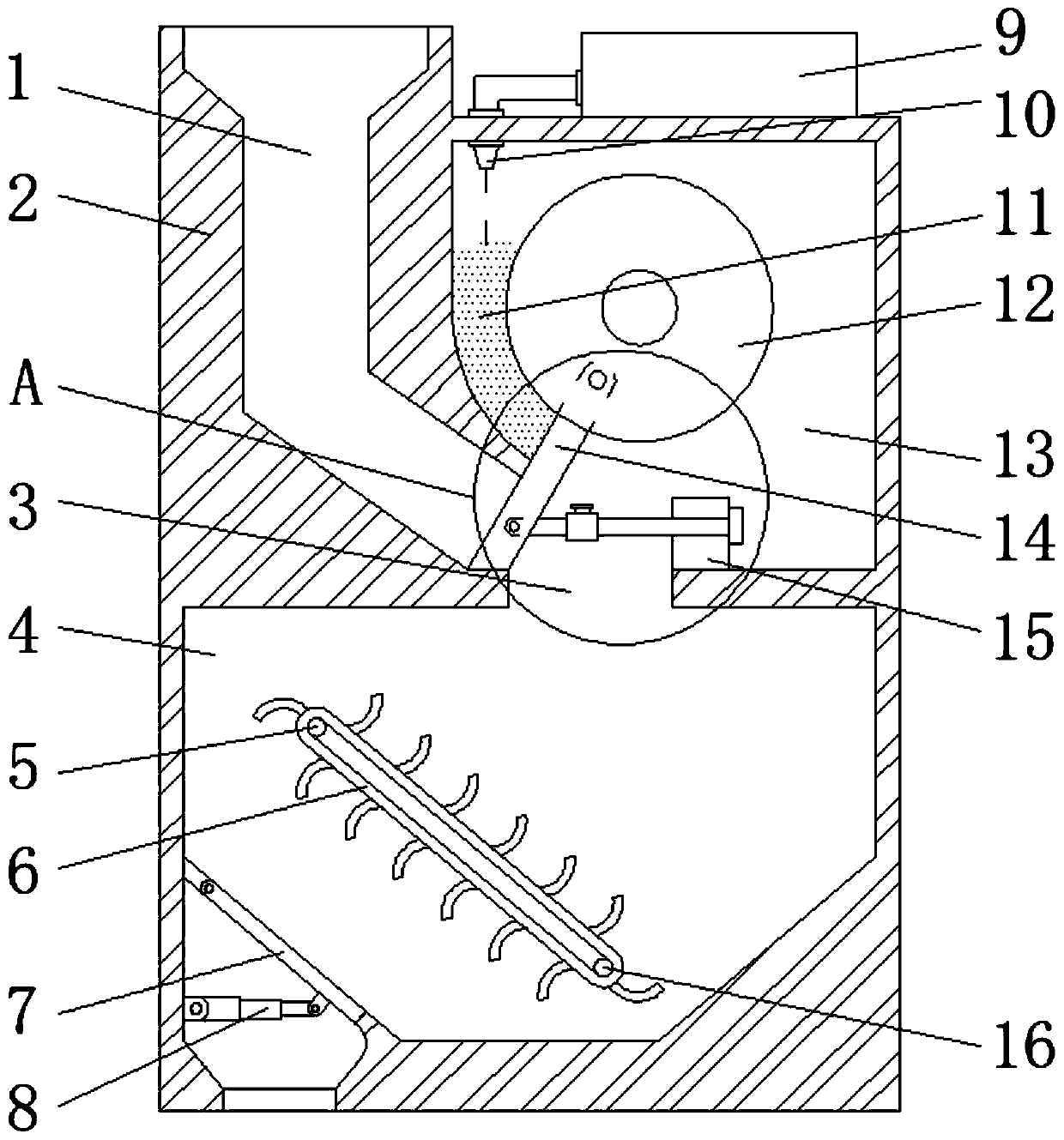

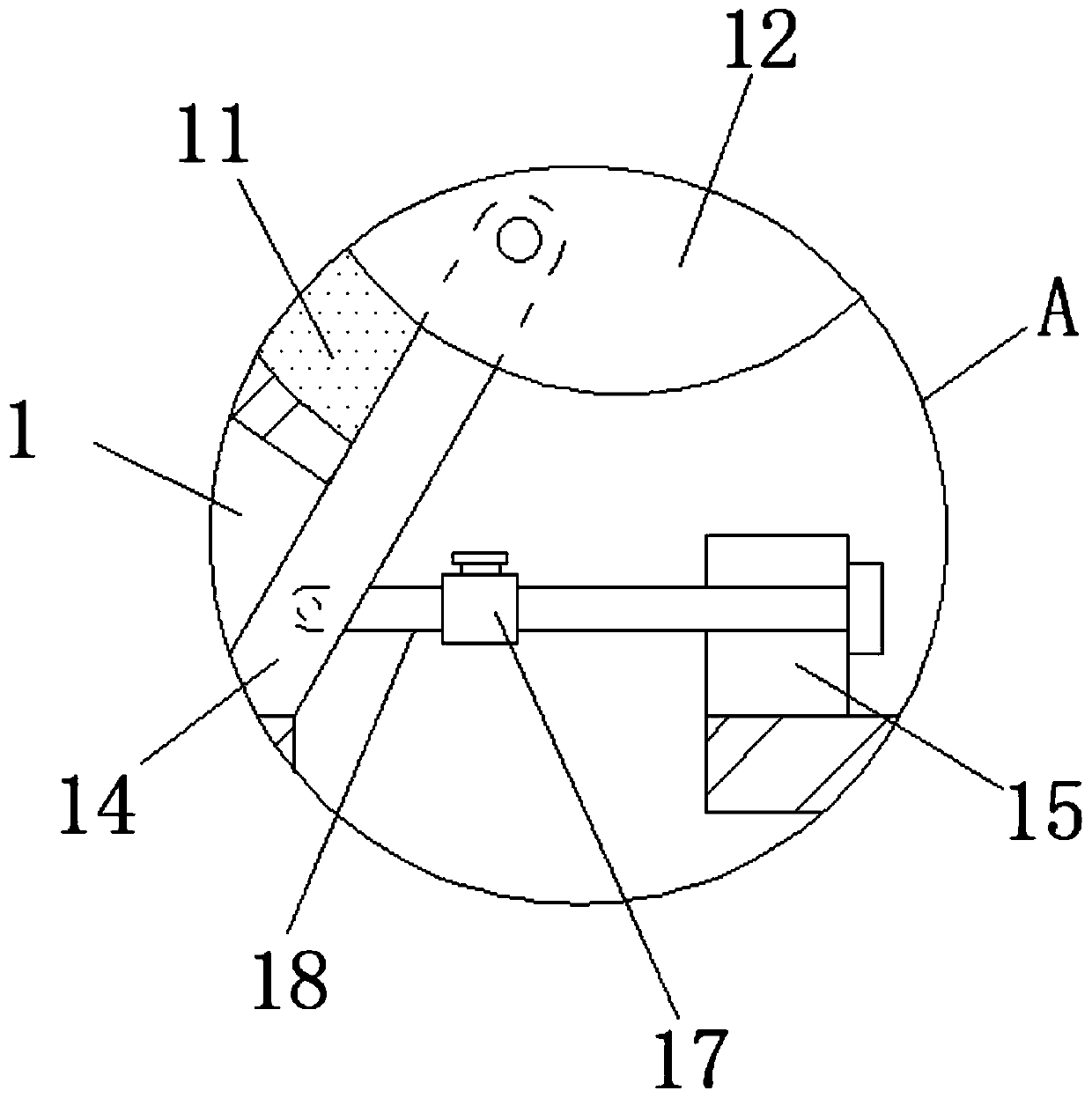

Image

Examples

Embodiment 1

[0038] A method for recycling sintered NdFeB waste, comprising the steps of:

[0039]Step 1, waste classification: classify different grades of NdFeB waste, and store each kind of NdFeB waste with similar composition separately for future use;

[0040] Step 2, surface dezincification: Put the NdFeB waste materials of 33SH to 42SH classified in step 1 into the pickling tank, and wash the NdFeB waste materials by pickling method. The pickling method adopts a concentration of 5 % hydrochloric acid solution is used as pickling solution to remove the galvanized layer on the surface of the NdFeB waste material to obtain non-coated NdFeB waste material;

[0041] Step 3, degreasing the surface: put the NdFeB waste obtained in Step 2 into the degreasing tank, and wash the NdFeB waste by alkaline washing method, which uses hot lye with a temperature of 65°C as the alkaline wash liquid to remove the oil and impurities on the surface of the NdFeB waste, and then use a high-pressure water...

Embodiment 2

[0051] A method for recycling sintered NdFeB waste. The difference between this embodiment and Embodiment 1 is that in step 2, the mixed waste of N33-N42 is selected for pickling processing; in step 5, 2% of the total weight of waste particles is added. A single piece of praseodymium neodymium alloy with a size of 18 mm is mixed and hydrogen crushed as a rare earth metal block, and the dehydrogenation temperature is 560 ° C; after the jet mill in step 6, the particle size of the obtained fine powder is 4.3; the sintering temperature in step 7 is 1060°C, and the holding time is 5 hours; during the aging treatment in step 8, hold the heat at 900°C for 2 hours at the first aging, and hold at 480°C for 5 hours at the second aging.

[0052] After testing, the properties of N33-N42 NdFeB waste materials are as follows:

[0053] Br Hcb Hcj BHmax Hk HK / Hcj density 12.7 12.26 16.05 38.88 15.24 0.95 7.552 12.86 12.33 15.98 39.67 15.1 0.95 7.546 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com