High-temperature-resistant and low-temperature-resistant environment-friendly chloroprene rubber adhesive and preparation method

A chloroprene rubber and adhesive technology, applied in the directions of chloroprene adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of long-term construction, irritating odor, etc., achieve convenient source, improve dissolution Sexual, easy-to-produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

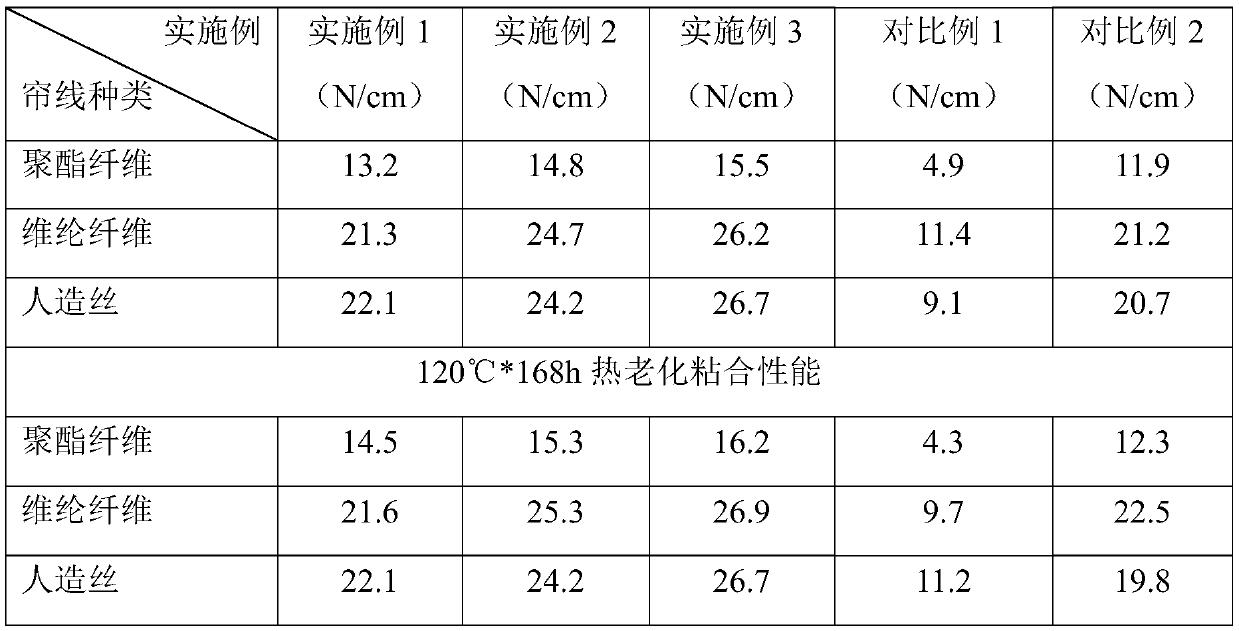

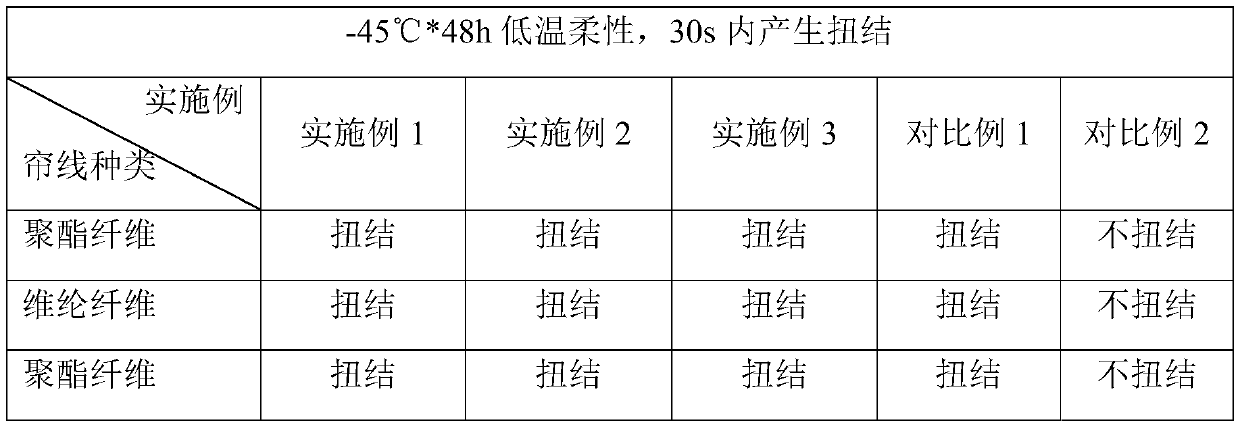

Embodiment 1

[0035] Weigh the following raw materials by weight: 100 parts of neoprene S-40, 5 parts of zinc oxide, 4 parts of magnesium oxide, 1 part of accelerator MTT-80, 0.8 parts of accelerator DM, 0.5 parts of stearic acid StA, 5 parts of N330 Carbon black, 20 parts of N550 carbon black, 20 parts of N774 carbon black, 1.5 parts of antioxidant 3100, 2 parts of antioxidant 4010NA, 3.5 parts of microcrystalline wax 9108, 5 parts of maleic anhydride grafted polybutadiene, of which maleic anhydride The amount of grafted maleic anhydride (MA) in the grafted polybutadiene = 7.5 wt%.

[0036] Cool the internal mixer with water, control the temperature of the working room of the internal mixer to not exceed 50°C, knead the chloroprene rubber in the internal mixer for 0.5min, then add stearic acid StA, anti-aging agent (anti-aging agent 3100, anti-aging agent 4010NA and microcrystalline wax 9108) in the mixer for 2min, then add N330 carbon black, N550 carbon black, N774 carbon black and mix fo...

Embodiment 2

[0039] Weigh the following raw materials by weight: 100 parts of neoprene S-40, 5 parts of zinc oxide, 4 parts of magnesium oxide, 1 part of accelerator MTT-80, 0.8 parts of accelerator DM, 0.5 parts of stearic acid StA, 15 parts of N330 Carbon black, 10 parts of N550 carbon black, 30 parts of N774 carbon black, 2 parts of anti-aging agent 3100, 2 parts of anti-aging agent 4010NA, 2.5 parts of protective wax 654, 10 parts of maleic anhydride grafted polybutadiene, wherein maleic anhydride grafted The amount of grafted maleic anhydride (MA) in branched polybutadiene=7.5wt%.

[0040] The internal mixer is cooled by water, and the temperature of the working room of the internal mixer is controlled not to exceed 50°C. The neoprene rubber is mixed in the internal mixer for 0.5min, and then stearic acid StA, anti-aging agent 3100, anti-aging agent 4010NA and protective Mix in wax 654 internal mixer for 2 minutes, then add N330 carbon black, N550 carbon black, N774 carbon black and m...

Embodiment 3

[0043] Weigh the following raw materials by weight: 100 parts of neoprene S-40, 5 parts of zinc oxide, 4 parts of magnesium oxide, 1 part of accelerator MTT-80, 0.8 parts of accelerator DM, 0.5 parts of stearic acid StA, 40 parts of N550 Carbon black, 35 parts of N774 carbon black, 2.5 parts of antioxidant 3100, 2 parts of antioxidant 4010NA, 15 parts of maleic anhydride grafted polybutadiene, wherein maleic anhydride (MA) in maleic anhydride grafted polybutadiene Grafting amount = 7.5 wt%.

[0044] Cool the internal mixer with water, control the temperature of the working room of the internal mixer to not exceed 50°C, knead the chloroprene rubber in the internal mixer for 0.5min, then add stearic acid StA, anti-aging agent (anti-aging agent 3100 and anti-aging agent 4010NA) internal mixer and mixed for 2 minutes, then added N550 carbon black, N774 carbon black and mixed for 3 minutes; finally, added zinc oxide, magnesium oxide and accelerator, maleic anhydride grafted polybut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com