Device and method for follow-up ultrasonic-assisted direct laser deposition of ceramic reinforced metal matrix composite material

A laser deposition, ultrasonic-assisted technology, applied in the field of additive manufacturing, can solve the problems of inconsistent tissue distribution and uneven stress distribution, and achieve the effects of high utilization, uniformity, and consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

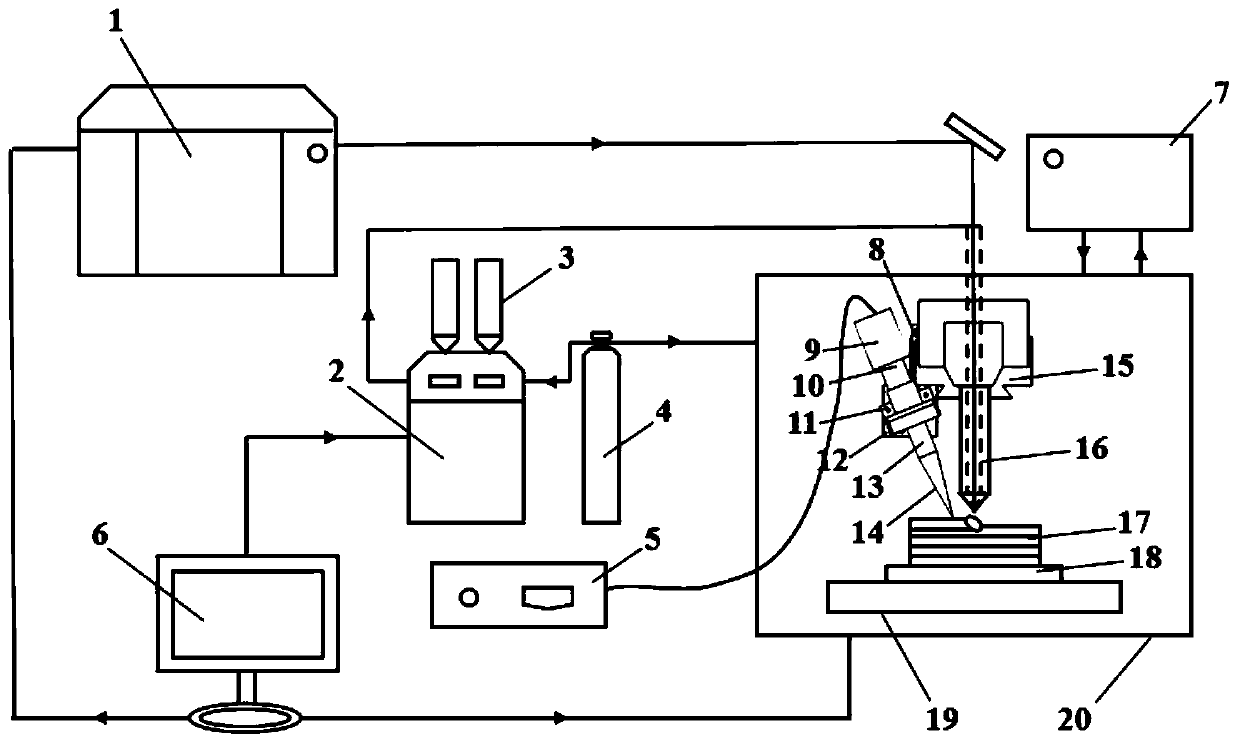

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

[0032] A device for directly laser-depositing ceramic-reinforced metal-matrix composites assisted by follow-up ultrasound, including a coaxial powder-feeding laser melting deposition forming system, a positioning and clamping device, and a follow-up ultrasonic system.

[0033] Among them, the coaxial powder feeding laser melting deposition forming system includes a laser 1, a powder feeder 2, a powder feeding cylinder 3, an industrial computer 6, a coaxial powder feeding nozzle 16, a metal substrate 18, a CNC machine tool 20, a cooling water circulation system 7 and Shielding gas system4. The numerically controlled machine tool 20 is provided with a dovetail guide rail 15 and a numerically controlled workbench 19. A metal substrate 18 is placed on the upper surface of the numerically controlled workbench 19, and the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com