Preparation method of Ni-P/nickel phosphide-carbon cloth three-dimensional self-supporting hydrogen evolution electrode material

A hydrogen evolution electrode, nickel phosphide technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor stability of hydrogen evolution electrode active materials, few hydrogen evolution active sites in electrodes, poor conductivity of nickel phosphide components, etc. Excellent electrical conductivity, many catalytically active sites, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

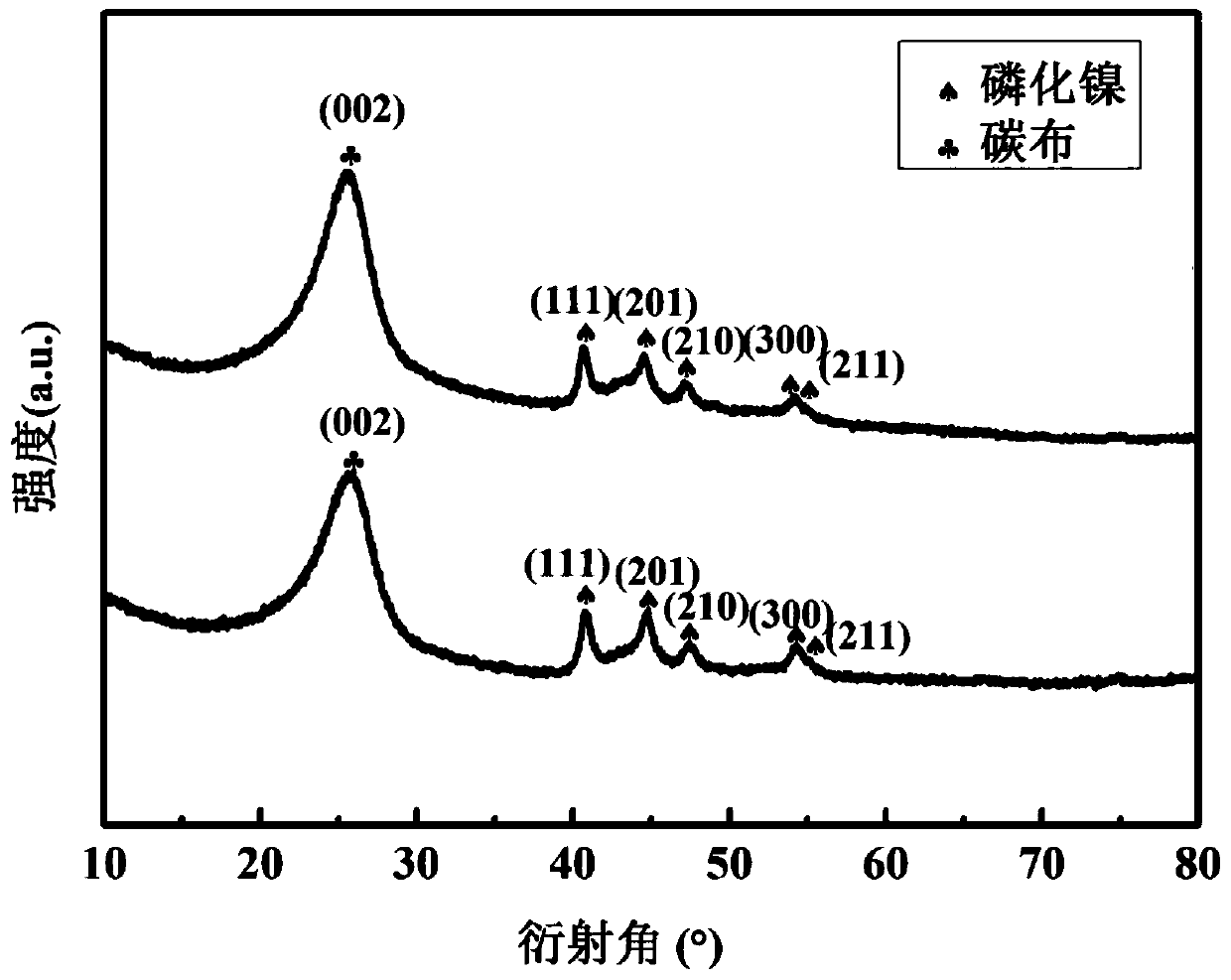

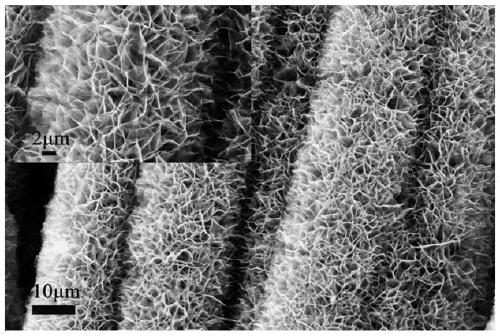

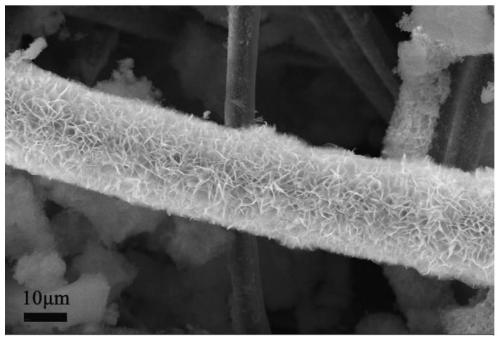

[0042] The invention discloses a preparation method of nickel phosphorus / nickel phosphide-carbon cloth three-dimensional self-supporting hydrogen evolution electrode material, including carbon cloth which needs acid impregnation, and the acid impregnation treatment steps of carbon cloth material are as follows:

[0043] Step 1. Add concentrated nitric acid with a volume of 100mL and a mass concentration of 65-68% into a 250mL beaker, and then cut eight pieces of carbon cloth with a thickness of 0.33mm into 2cm×2cm and add them to the beaker filled with concentrated nitric acid. 250mL beaker, and seal the mouth of the beaker with plastic wrap, and leave it at room temperature for 45-48 hours to carry out acid impregnation and hydrophilic modification on the carbon cloth;

[0044] Step Ⅱ. After standing still, place the beaker in an ultrasonic cleaner for ultrasonic treatment. The ultrasonic cleaner is filled with deionized water at a temperature of 20-30°C. The power of the clea...

Embodiment 1

[0062] Step 1. Add 0.7270g of nickel nitrate and 0.7010g of hexamethylenetetramine into a beaker filled with 18mL of deionized water in turn, then place the beaker on a magnetic stirrer and stir at room temperature to dissolve it;

[0063] Step 2. Transfer the solution stirred in step 1 to a 25mL polytetrafluoroethylene-lined stainless steel reaction kettle, and at the same time put the acid-impregnated square carbon cloth with a length and width of 2cm into the stainless steel for reaction. In the kettle, tighten the sealing cover of the stainless steel reaction kettle and transfer it to the electric furnace. The furnace temperature of the electric furnace is 100 ° C, and the hydrothermal reaction is carried out at this temperature for 10 hours; after the reaction, the power supply of the electric furnace is turned off, and the stainless steel reaction Take out the kettle from the electric furnace and open the sealing cover of the reaction kettle, take the carbon cloth out of ...

Embodiment 2

[0076] Step 1. Add 0.70g of nickel nitrate and 0.70g of hexamethylenetetramine into a beaker filled with 15mL of deionized water in turn, then place the beaker on a magnetic stirrer and stir at room temperature to dissolve it;

[0077] Step 2. Transfer the solution stirred in step 1 to a 25mL polytetrafluoroethylene-lined stainless steel reaction kettle, and at the same time put the acid-impregnated square carbon cloth with a length and width of 2cm into the stainless steel for reaction. In the kettle, tighten the sealing cover of the stainless steel reaction kettle and transfer it to the electric furnace. The furnace temperature of the electric furnace is 100 ° C, and the hydrothermal reaction is carried out at this temperature for 10 hours; after the reaction, the power supply of the electric furnace is turned off, and the stainless steel reaction Take out the kettle from the electric furnace and open the sealing cover of the reaction kettle, take the carbon cloth out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com