Gallium oxide crystal and growth method and growth device thereof

A growth method and crystal growth technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of high price, high melting point, high hardness, etc., and achieve the goal of reducing growth cost, avoiding adhesion, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

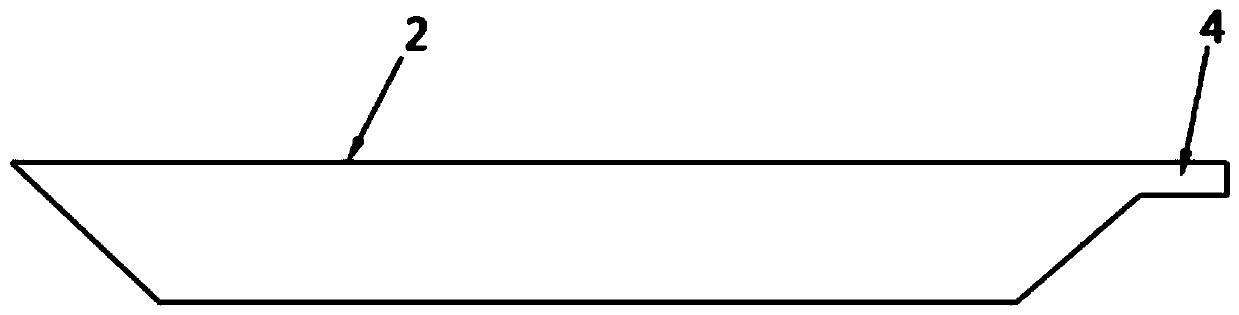

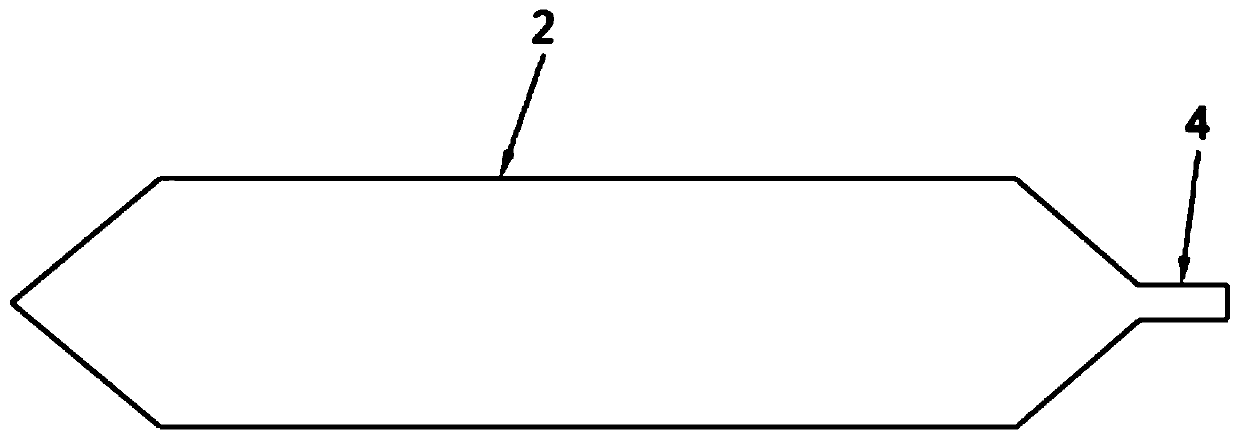

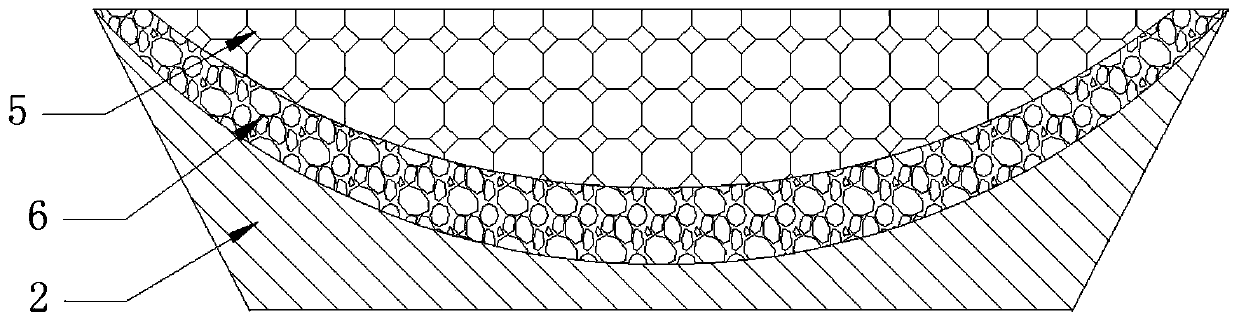

[0029] This embodiment 1 provides a growth device for gallium oxide crystals, such as Figure 1~4 As shown, it includes a growth furnace 1, a crucible 2, a heater 3 and a transmission device. Wherein, the crucible 2 is a boat-shaped PBN crucible, and one end of the crucible 2 is provided with a seed crystal tank 4 . During crystal growth, the crucible 2 is placed in the growth furnace 1 and heated by the heater 3 to raise the temperature, and the transmission device is used to drive the crucible 2 or the heater 3 to move horizontally. In addition, the heating method of the growth furnace is medium frequency induction or resistance heating. The growth device of this embodiment mainly involves improving the structure of the crucible, and the growth furnace adopts an existing crystal growth furnace, which is provided with a heater capable of heating the crucible and a transmission device for driving the crucible or the heater to move horizontally. Those skilled in the art shoul...

Embodiment 2

[0033] The gallium oxide crystal growth device of Example 1 is used to prepare gallium oxide crystals. The heating method of the growth furnace is medium-frequency induction heating. The specific operation is as follows: 1 kg of gallium oxide raw material and 5 kg of gallium are loaded into a PBN crucible, and placed in a seed crystal tank. into the gallium oxide seed crystal. Put the PBN crucible into the growth furnace, and evacuate the growth furnace to 10 -5 Pa, filled with high-purity argon as a protective gas. Raise the temperature to 1740°C, melt the gallium oxide raw material, make the gallium oxide melt contact with the seed crystal, and complete the seeding. Move the PBN crucible horizontally along the direction of the seed crystal to start crystal growth, and the horizontal moving speed of the PBN crucible is 0.5mm / h. After the crystal growth is finished, open the furnace door, take out the PBN crucible and cool it down, then heat the PBN crucible to 35°C in an ov...

Embodiment 3

[0036] The gallium oxide crystal growth device of Example 1 is used to prepare gallium oxide crystals. The heating method of the growth furnace is medium-frequency induction heating. The specific operation is as follows: 3 kg of gallium oxide raw material and 3 kg of gallium are loaded into a PBN crucible, and placed in a seed crystal tank. into the gallium oxide seed crystal. Put the PBN crucible into the growth furnace, and evacuate the growth furnace to 10 -5 Pa, filled with high-purity argon as a protective gas. Raise the temperature to 1740°C, melt the gallium oxide raw material, make the gallium oxide melt contact with the seed crystal, and complete the seeding. Move the heater horizontally along the direction away from the seed crystal to start crystal growth, and the horizontal moving speed of the heater is 10mm / h. After the crystal growth is finished, open the furnace door, take out the PBN crucible and cool it down, then use an oven to heat the PBN crucible to 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com