Negative ion polyurethane resin surface layer slurry for leather

A technology of polyurethane resin and surface layer slurry is applied in the field of automotive interior materials, which can solve the problems of material performance decline, ultrafine powder performance deterioration, and the inability of a single particle to exist stably, and achieves the effect of solving compatibility problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

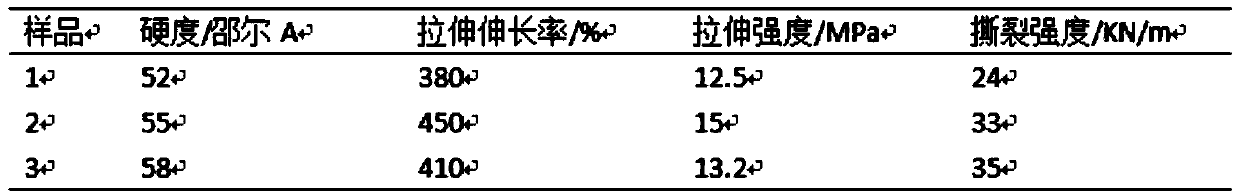

Embodiment 1

[0023] A kind of surface layer slurry of negative ion polyurethane resin for leather, is made up of following components by mass parts:

[0024] Waterborne polyurethane resin (Covestro: Bayhydrol A 2601): 100 parts

[0025] Water: 20-40 parts

[0026] Water-based ink (BASF: Joncryl 678): 10-30 parts

[0027] Negative ion additive: 3 to 5 parts.

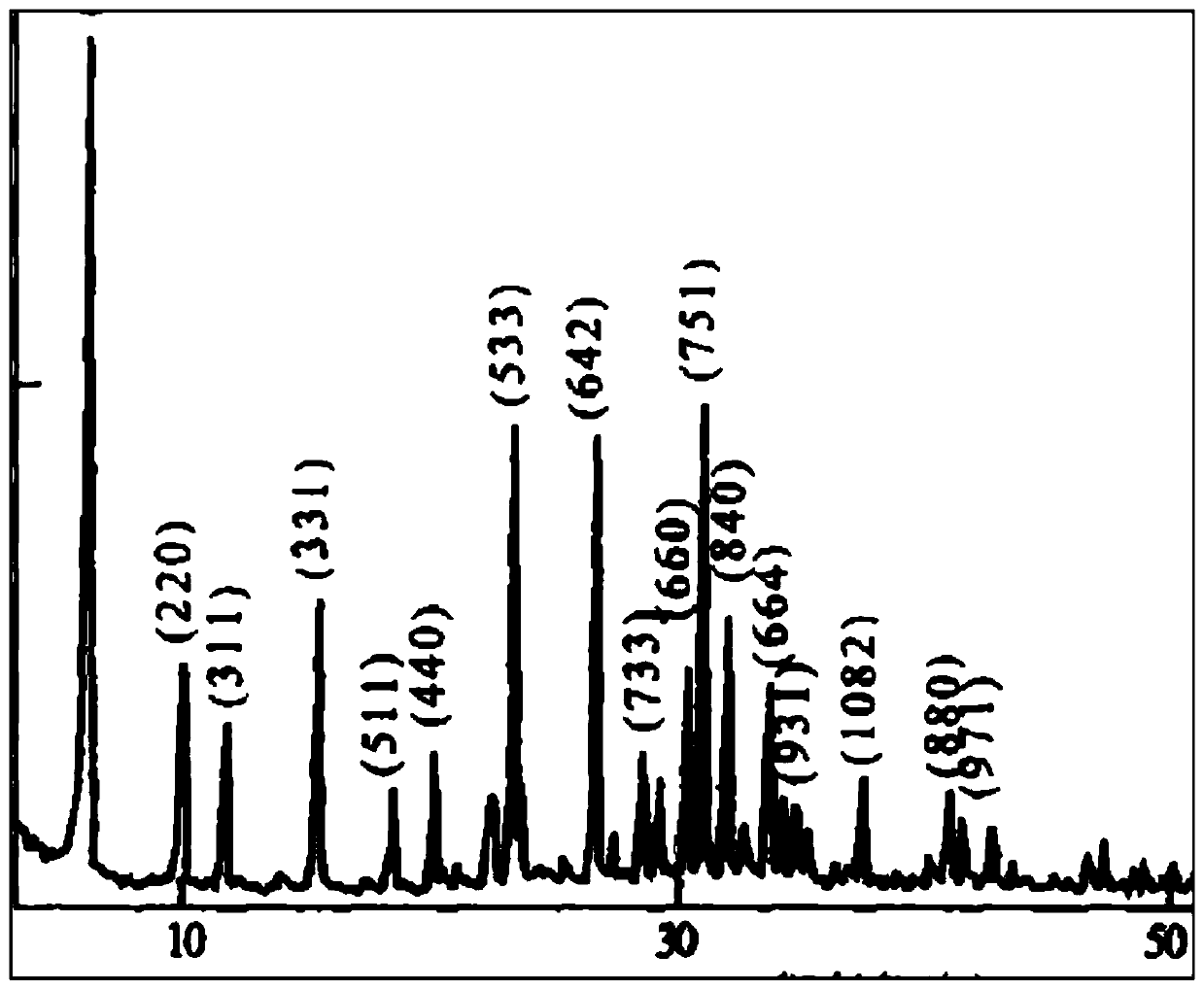

[0028] Further, the negative ion additive is a tourmaline@13X molecular sieve with a core-shell structure, and the preparation method of the tourmaline@13X molecular sieve is as follows:

[0029] a, by mechanical shearing, the tourmaline is made into a powder A with a particle size of 6-20 microns;

[0030] b. Mix sodium metaaluminate, sodium hydroxide, sodium silicate, and water according to the following molar ratio, SiO 2 / Al 2 o 3 =3~5;Na 2 O / SiO 2 =1~1.5;H 2 O / Na 2 O=35~65; get Sol B after mixing evenly;

[0031] c. Add powder A to sol B, the mass ratio is A / B=3~5%, continue stirring evenly, and let stand at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com